SECTION 5: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Loose mounting bolts.

•Worn switch.

•Worn or damaged cords and plugs.

•Damaged or worn wheel rubber.

•Any other condition that could hamper the safe operation of this machine.

Cleaning

Frequently

•After the first 200 hours of use, or after the first month, change the gearbox oil with 5.1 fluid ounces of a good automotive grade

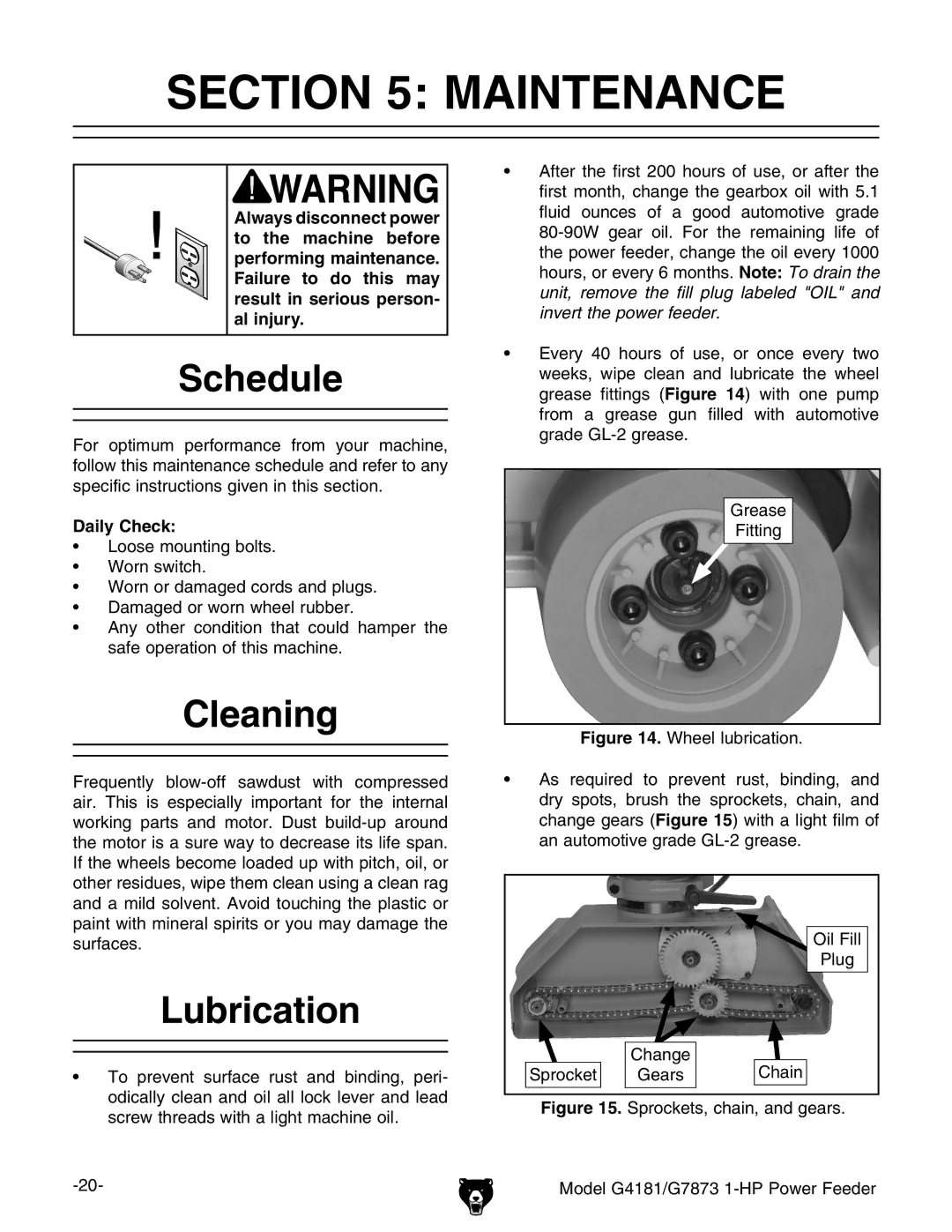

•Every 40 hours of use, or once every two weeks, wipe clean and lubricate the wheel grease fittings (Figure 14) with one pump from a grease gun filled with automotive grade

Grease

Fitting

Figure 14. Wheel lubrication.

•As required to prevent rust, binding, and dry spots, brush the sprockets, chain, and change gears (Figure 15) with a light film of an automotive grade GL-2 grease.

surfaces.

Lubrication

• | To prevent surface rust and binding, peri- |

| odically clean and oil all lock lever and lead |

Sprocket

Change

Gears

Oil Fill

Plug

Chain

screw threads with a light machine oil. |