Base Mounting

Position the power feeder on the table top to determine where to drill your base mounting holes, so you can maximize power feeder swing and adjustment options.

There are two mounting options available: Through Bolt Mounting and Direct Mounting (discussed on Page 16). Choose an option that suits your requirements.

Whichever way you mount your power feeder, you must be able to use the handcranks and lock levers to position the rubber wheels parallel with the table surface and 1⁄8" lower than the thickness of your workpiece.

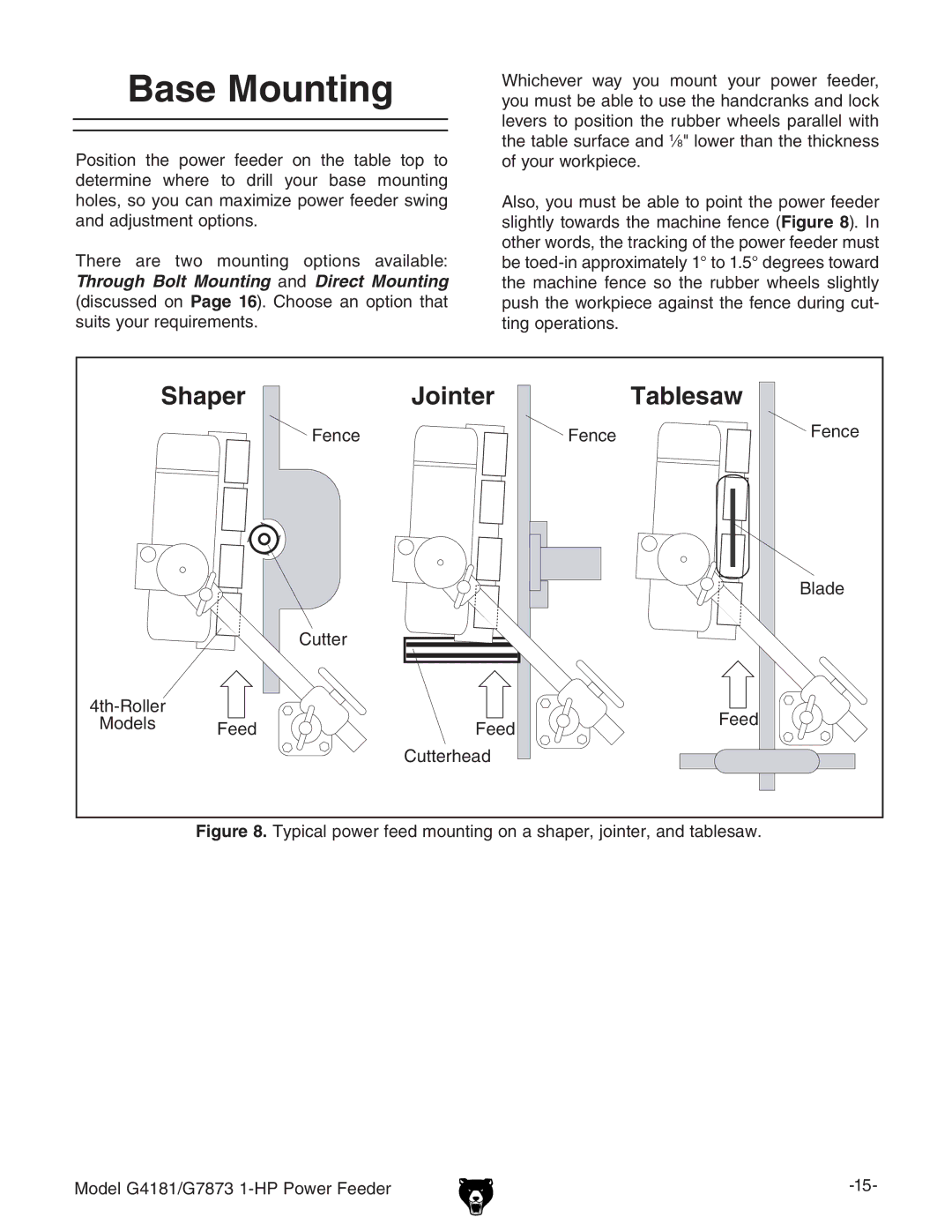

Also, you must be able to point the power feeder slightly towards the machine fence (Figure 8). In other words, the tracking of the power feeder must be

Shaper | Jointer | Tablesaw | |

| ;ZcXZ | ;ZcXZ | ;ZcXZ |

|

|

| 7aVYZ |

| 8jiiZg |

|

|

)i]"GdaaZg |

|

| ;ZZY |

BdYZah | ;ZZY | ;ZZY | |

|

| ||

|

| 8jiiZg]ZVY |

|

Figure 8. Typical power feed mounting on a shaper, jointer, and tablesaw.

Model G4181/G7873 |