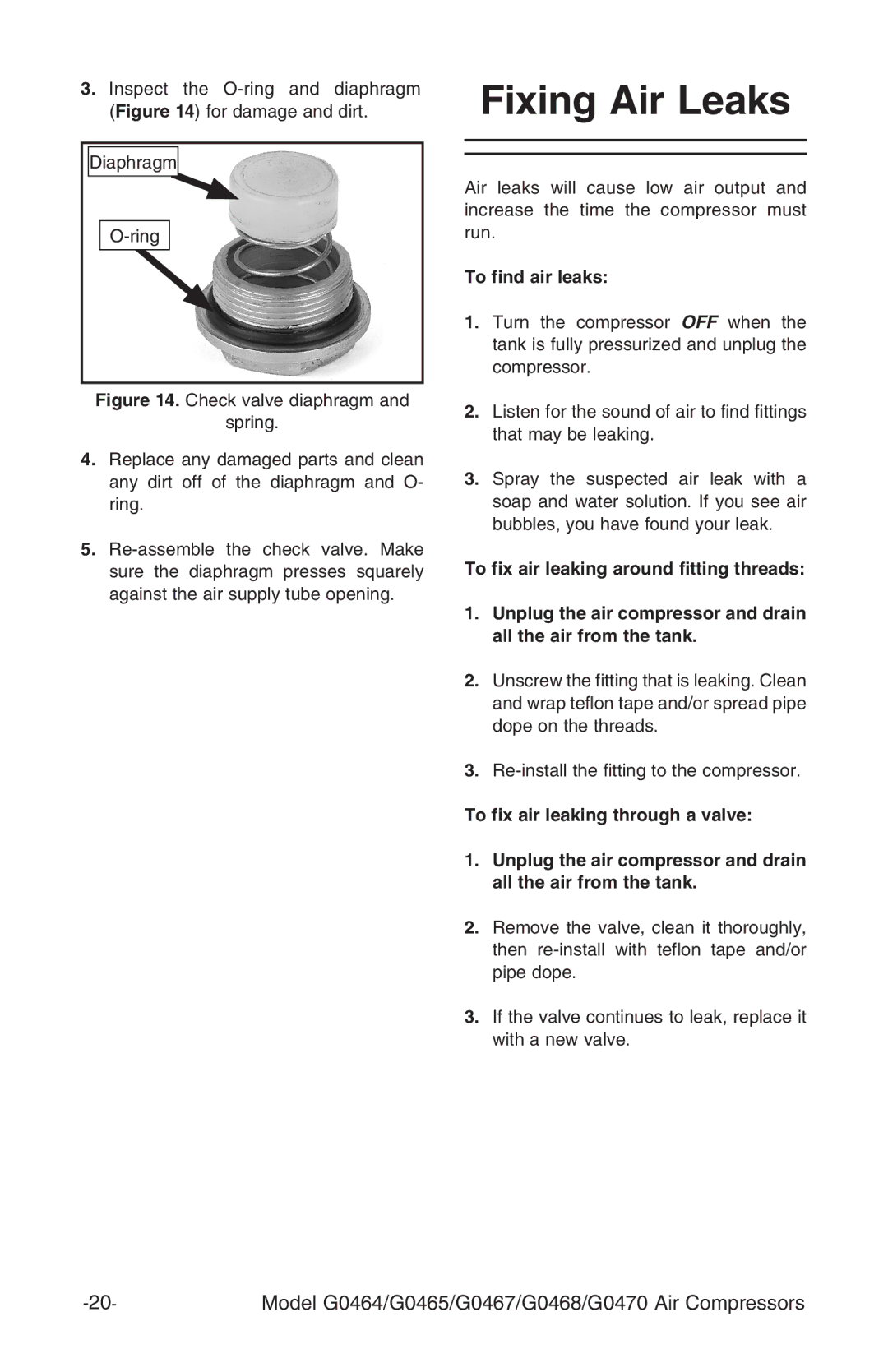

3.Inspect the

Diaphragm

Figure 14. Check valve diaphragm and

spring.

4.Replace any damaged parts and clean any dirt off of the diaphragm and O- ring.

5.Re-assemble the check valve. Make sure the diaphragm presses squarely against the air supply tube opening.

Fixing Air Leaks

Air leaks will cause low air output and increase the time the compressor must run.

To find air leaks:

1.Turn the compressor OFF when the tank is fully pressurized and unplug the compressor.

2.Listen for the sound of air to find fittings that may be leaking.

3.Spray the suspected air leak with a soap and water solution. If you see air bubbles, you have found your leak.

To fix air leaking around fitting threads:

1.Unplug the air compressor and drain all the air from the tank.

2.Unscrew the fitting that is leaking. Clean and wrap teflon tape and/or spread pipe dope on the threads.

3.

To fix air leaking through a valve:

1.Unplug the air compressor and drain all the air from the tank.

2.Remove the valve, clean it thoroughly, then

3.If the valve continues to leak, replace it with a new valve.

Model G0464/G0465/G0467/G0468/G0470 Air Compressors |