G5979 specifications

The Grizzly G5979 is a versatile and robust woodworking lathe designed for both professional and amateur woodworkers. Known for its durability and precision, the G5979 model stands out in the woodworking community for its innovative features and user-friendly design.One of the main characteristics of the Grizzly G5979 is its powerful 1 HP motor, providing ample torque for turning a wide variety of wood pieces. The variable speed range, adjustable from 600 to 3200 RPM, gives users the flexibility to select the optimal speed for their specific project, whether it’s shaping delicate spindles or roughing out larger bowls.

The lathe boasts a solid cast iron construction, which not only contributes to stability during operation but also helps minimize vibrations. This ensures a smooth finish on the woodwork and allows for greater accuracy in shaping the material. Additionally, the bed of the lathe is designed to accommodate longer workpieces, making it suitable for projects of varying sizes.

Another key feature of the Grizzly G5979 is its swiveling headstock, which can be rotated 180 degrees. This functionality enhances the versatility of the lathe, enabling users to easily access different angles for intricate designs and detailed work. Enhancing this feature is an easy-to-read scale for adjustments, making it effortless for woodworkers to make precise changes.

The lathe also includes a built-in tailstock with a precision live center, allowing for secure and accurate positioning of workpieces. An easy to operate handwheel enables fine adjustments, adding to the overall convenience of the device.

The G5979 is equipped with a sturdy tool rest that can be adjusted for height and angle, facilitating smoother transitions during turning. The tool rest is designed for easy installation and removal, enhancing the lathe's operation efficiency.

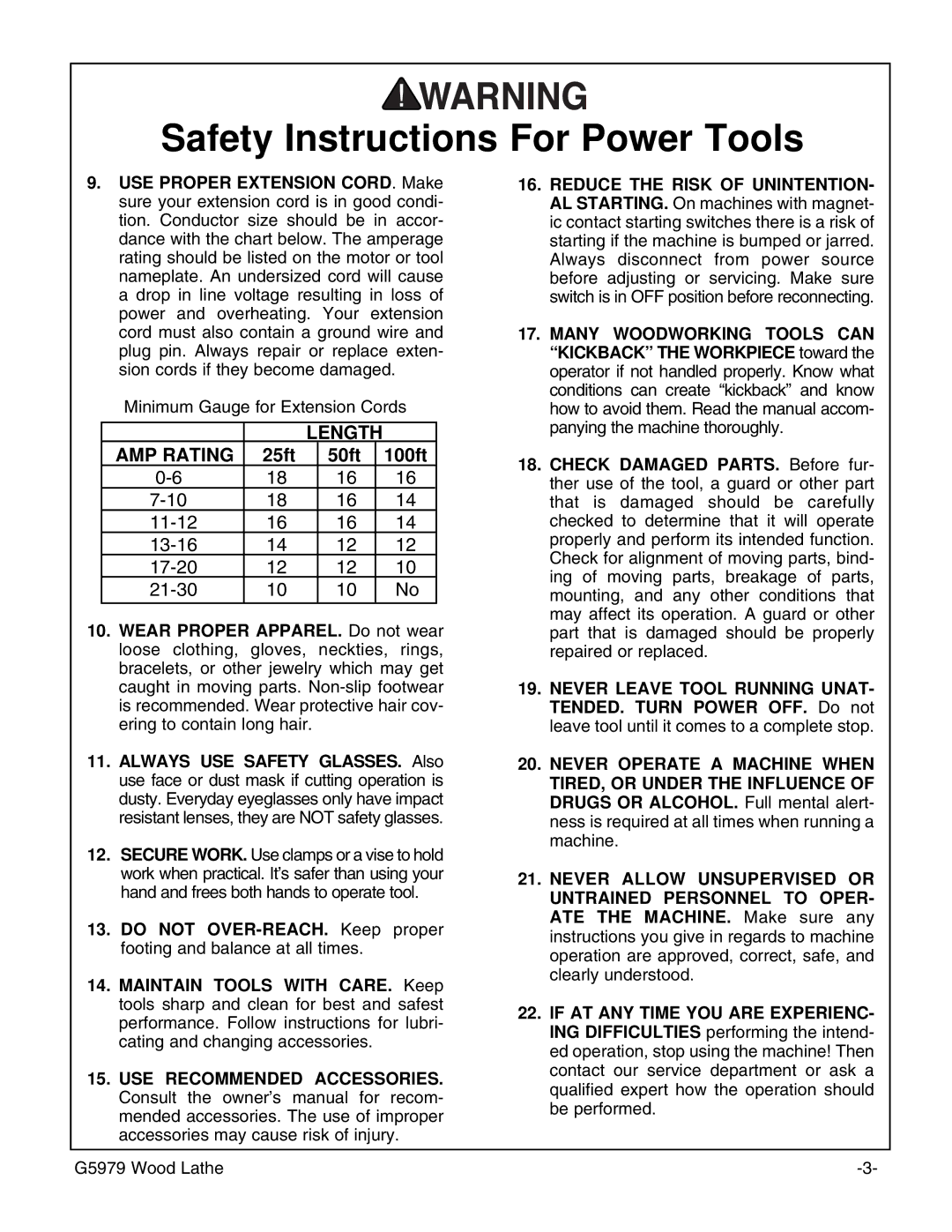

Safety features of the Grizzly G5979 include a safety switch and an emergency stop button, ensuring that users can quickly halt operation in case of any unforeseen issues. Moreover, the overall design reflects a commitment to user safety and ease of use, making it an appealing choice for woodworkers at any skill level.

In summary, the Grizzly G5979 woodworking lathe represents a great blend of power, precision, and safety. Its array of features and technologies ensures that users can tackle a wide range of woodworking projects effectively. Whether you are an experienced craftsman or a beginner, the G5979 is a solid investment for any woodworking shop.