To adjust V-belt tension:

1.Loosen the motor mount bolt.

2.Shift the motor up or down to increase or decrease the

3.Check the

To replace the V-belts:

1.Remove the blade.

2.Adjust the arbor so it is up all the way and in the 90¡ position.

3.Place a board under the motor and loosen the motor mount bolt. Slowly lower the arbor until the motor rests on the board, allowing the belts to be loose on the pulleys.

4.Pull off the old

5.Raise the arbor and remove the board to adjust the

6.Tighten the motor mount bolt.

Keep clothing rolled up and out of the way of machinery and keep hair pulled back.

Wear safety glasses dur- ing the entire mainte- nance process. Failure to comply may result in serious personal injury.

Lubrication

The shielded ball bearings in the motor and throughout the Model G7209/10 require no fur- ther lubrication during their lifetime. When they do wear out, replacements can be obtained through the Grizzly Parts Department.

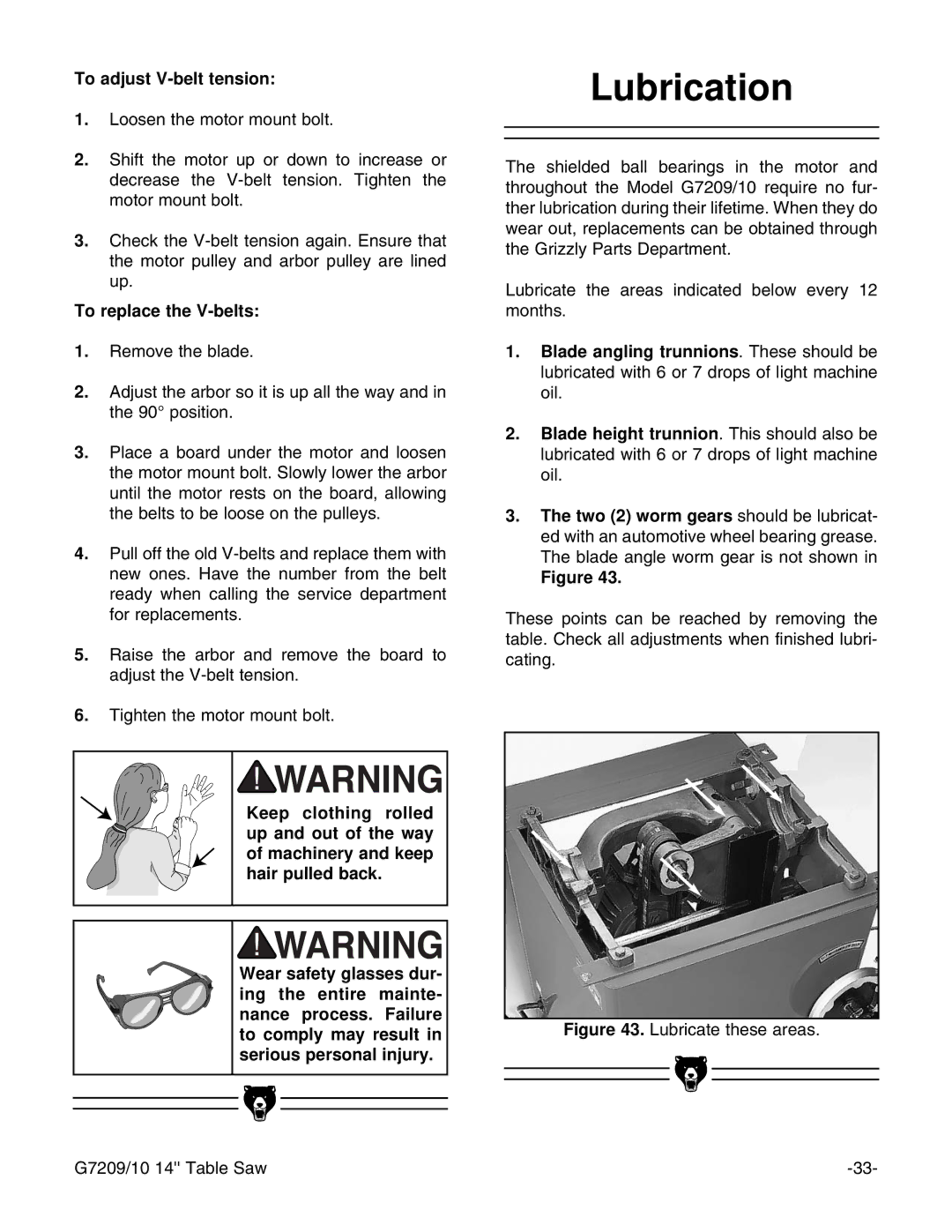

Lubricate the areas indicated below every 12 months.

1.Blade angling trunnions. These should be lubricated with 6 or 7 drops of light machine oil.

2.Blade height trunnion. This should also be lubricated with 6 or 7 drops of light machine oil.

3.The two (2) worm gears should be lubricat- ed with an automotive wheel bearing grease. The blade angle worm gear is not shown in

Figure 43.

These points can be reached by removing the table. Check all adjustments when finished lubri- cating.

Figure 43. Lubricate these areas.

G7209/10 14'' Table Saw |