Before using your Grizzly Air Compressor, follow these steps before the first use:

1.Remove all packing materials and the pro- tective plastic plugs from the cylinder head and oil plug. Do not remove the yellow cap underneath the black plastic cover of the pressure switch housing.

2.Screw the air filter(s) into the cylinder head(s).

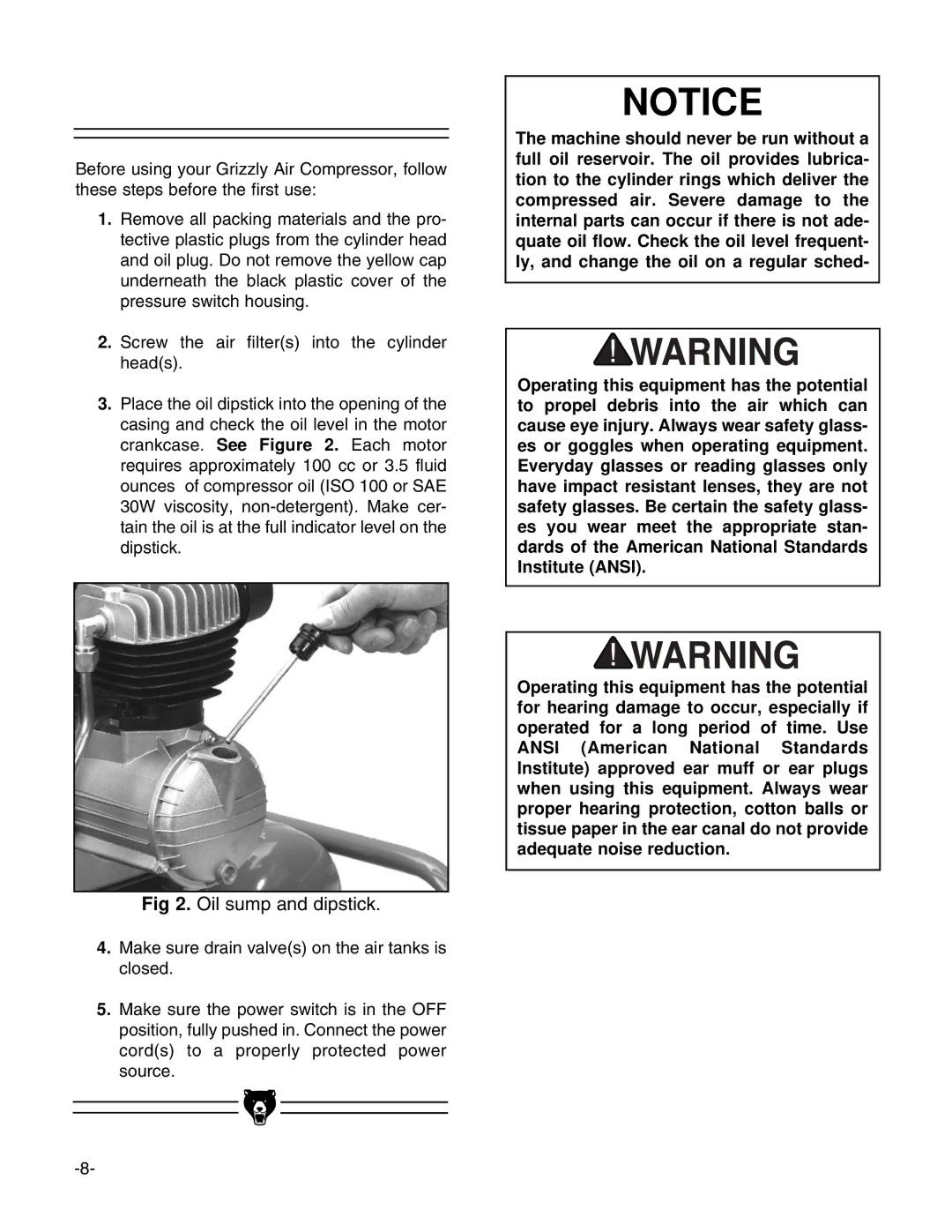

3.Place the oil dipstick into the opening of the casing and check the oil level in the motor crankcase. See Figure 2. Each motor requires approximately 100 cc or 3.5 fluid ounces of compressor oil (ISO 100 or SAE 30W viscosity,

Fig 2. Oil sump and dipstick.

4.Make sure drain valve(s) on the air tanks is closed.

5.Make sure the power switch is in the OFF position, fully pushed in. Connect the power cord(s) to a properly protected power source.

NOTICE

The machine should never be run without a full oil reservoir. The oil provides lubrica- tion to the cylinder rings which deliver the compressed air. Severe damage to the internal parts can occur if there is not ade- quate oil flow. Check the oil level frequent- ly, and change the oil on a regular sched-

Operating this equipment has the potential to propel debris into the air which can cause eye injury. Always wear safety glass- es or goggles when operating equipment. Everyday glasses or reading glasses only have impact resistant lenses, they are not safety glasses. Be certain the safety glass- es you wear meet the appropriate stan- dards of the American National Standards Institute (ANSI).

Operating this equipment has the potential for hearing damage to occur, especially if operated for a long period of time. Use ANSI (American National Standards Institute) approved ear muff or ear plugs when using this equipment. Always wear proper hearing protection, cotton balls or tissue paper in the ear canal do not provide adequate noise reduction.