OPERATION

Inserting Attachments

Your kit comes with a large variety of dif- ferent attachments ranging from grinding stones, sanding discs and sleeves, buffing pads and carving tools. There are two dif- ferent collet sizes, 7⁄64" and 1⁄8" diameter.

Some of the cutting wheels, polishing tips and other accessories need to be attached or inserted into another shaft or mandrel in order to be used. If you are using one of these, first thread the accessory onto the shaft.

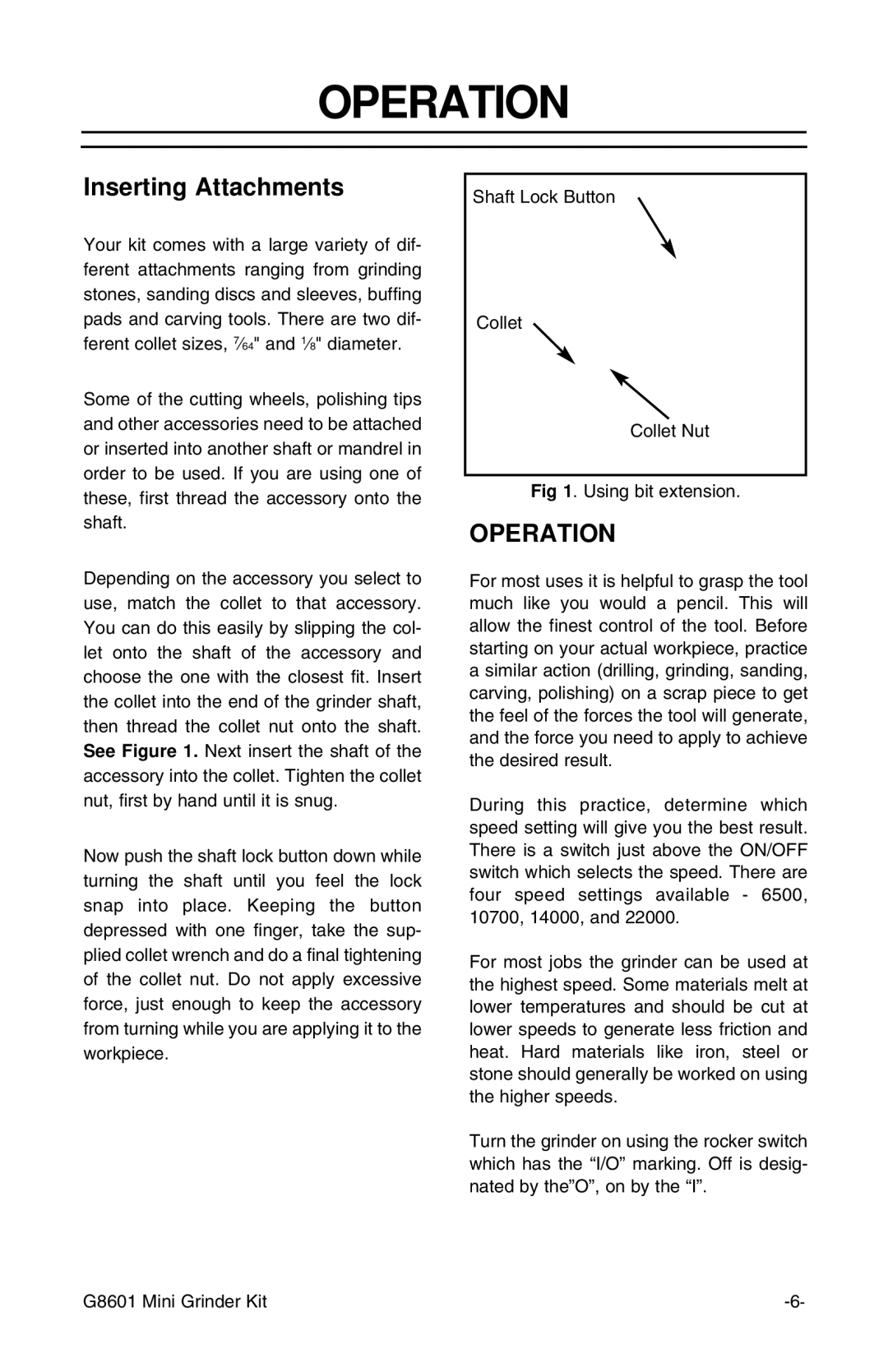

Depending on the accessory you select to use, match the collet to that accessory. You can do this easily by slipping the col- let onto the shaft of the accessory and choose the one with the closest fit. Insert the collet into the end of the grinder shaft, then thread the collet nut onto the shaft. See Figure 1. Next insert the shaft of the accessory into the collet. Tighten the collet nut, first by hand until it is snug.

Now push the shaft lock button down while turning the shaft until you feel the lock snap into place. Keeping the button depressed with one finger, take the sup- plied collet wrench and do a final tightening of the collet nut. Do not apply excessive force, just enough to keep the accessory from turning while you are applying it to the workpiece.

Shaft Lock Button

Collet

Collet Nut

Fig 1. Using bit extension.

OPERATION

For most uses it is helpful to grasp the tool much like you would a pencil. This will allow the finest control of the tool. Before starting on your actual workpiece, practice a similar action (drilling, grinding, sanding, carving, polishing) on a scrap piece to get the feel of the forces the tool will generate, and the force you need to apply to achieve the desired result.

During this practice, determine which speed setting will give you the best result. There is a switch just above the ON/OFF switch which selects the speed. There are four speed settings available - 6500, 10700, 14000, and 22000.

For most jobs the grinder can be used at the highest speed. Some materials melt at lower temperatures and should be cut at lower speeds to generate less friction and heat. Hard materials like iron, steel or stone should generally be worked on using the higher speeds.

Turn the grinder on using the rocker switch which has the “I/O” marking. Off is desig- nated by the”O”, on by the “I”.

G8601 Mini Grinder Kit |