SECTION 4: ASSEMBLY

Securing Motor

to Bench

The sanding motor body must be securely mount- ed before the machine can be safely used.

There are four 3Ú8" holes in the motor base which can be used to secure the machine to a tool stand or workbench. Figure 2 shows the approximate dimensions of the hole pattern. It is best to use the actual motor base as a guide for positioning the holes.

The Sander can be temporarily mounted by using bolts with wing nuts. The Sander must be secure- ly mounted because sanding forces can be signif- icant and could cause the sanding machine to move.

Attaching Flap Sander

The Flap Sander attachment is secured with a couple of ties which hold the assembly together when it is not mounted on the motor shaft. Carefully release the ties and remove them. Hold the assembly together by grasping both end plates at the same time.

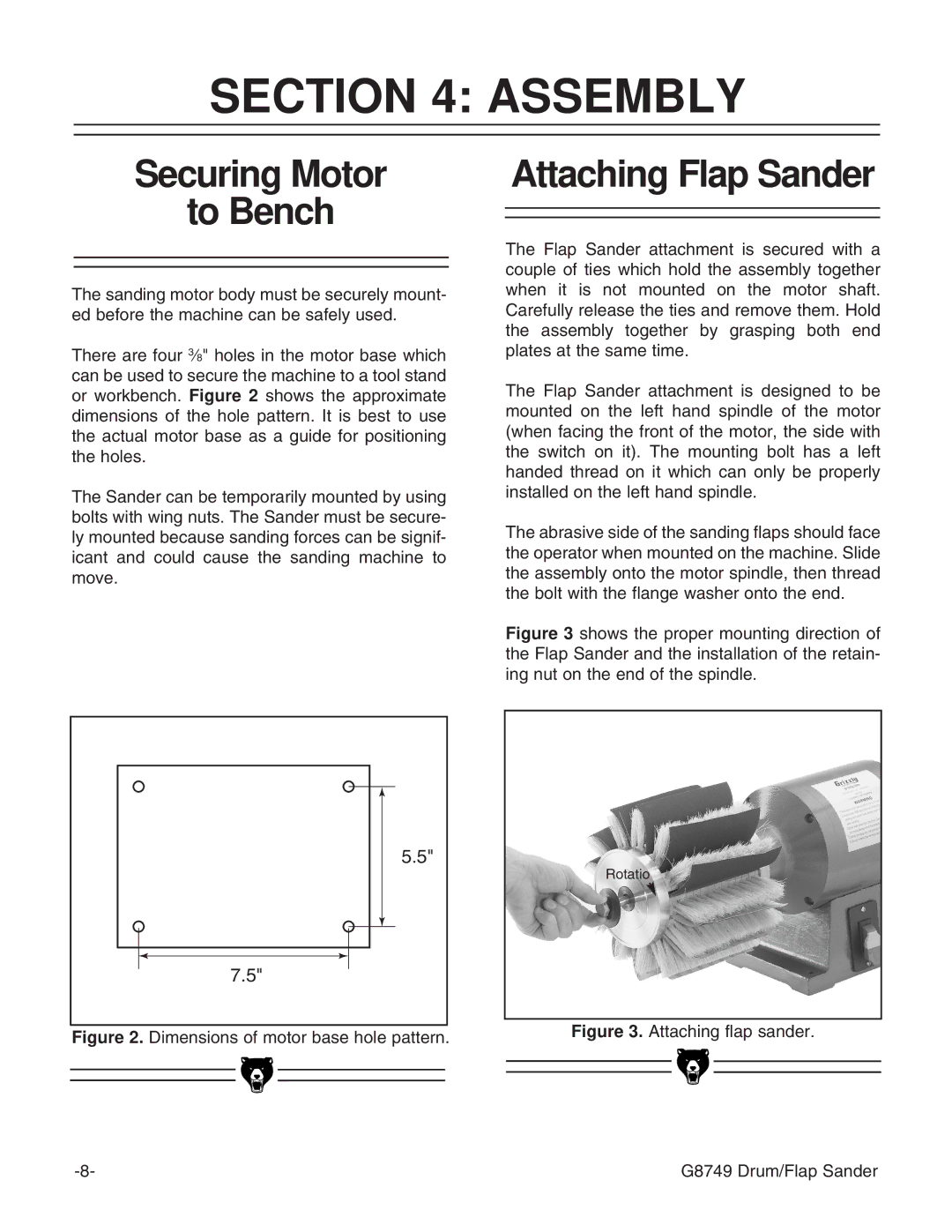

The Flap Sander attachment is designed to be mounted on the left hand spindle of the motor (when facing the front of the motor, the side with the switch on it). The mounting bolt has a left handed thread on it which can only be properly installed on the left hand spindle.

The abrasive side of the sanding flaps should face the operator when mounted on the machine. Slide the assembly onto the motor spindle, then thread the bolt with the flange washer onto the end.

Figure 3 shows the proper mounting direction of the Flap Sander and the installation of the retain- ing nut on the end of the spindle.

5.5"

7.5" |

Figure 2. Dimensions of motor base hole pattern.

Rotatio

Figure 3. Attaching flap sander.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| G8749 Drum/Flap Sander | ||

|

|

|

| |||