Attaching Sanding

Drum

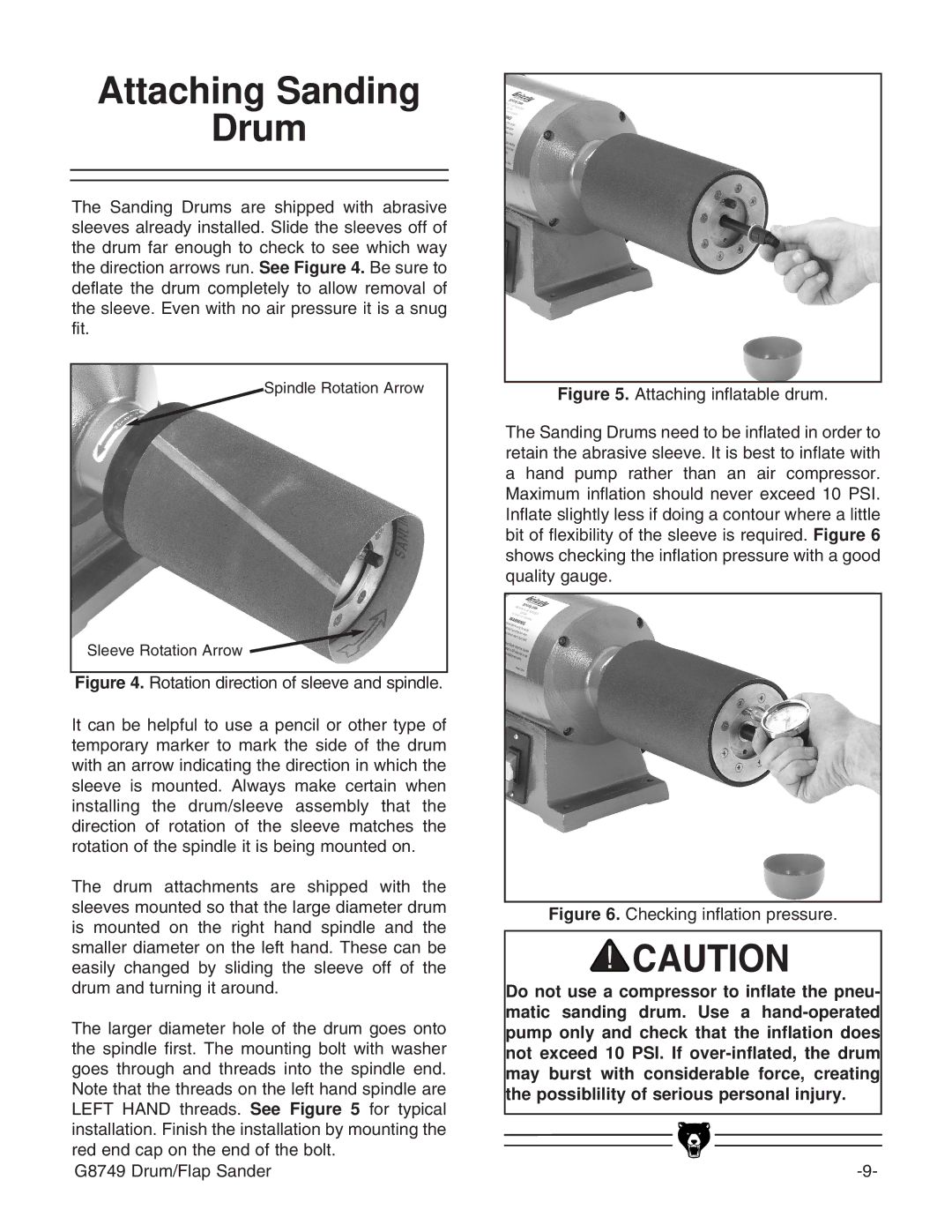

The Sanding Drums are shipped with abrasive sleeves already installed. Slide the sleeves off of the drum far enough to check to see which way the direction arrows run. See Figure 4. Be sure to deflate the drum completely to allow removal of the sleeve. Even with no air pressure it is a snug fit.

Spindle Rotation Arrow

Sleeve Rotation Arrow ![]()

Figure 4. Rotation direction of sleeve and spindle.

It can be helpful to use a pencil or other type of temporary marker to mark the side of the drum with an arrow indicating the direction in which the sleeve is mounted. Always make certain when installing the drum/sleeve assembly that the direction of rotation of the sleeve matches the rotation of the spindle it is being mounted on.

The drum attachments are shipped with the sleeves mounted so that the large diameter drum is mounted on the right hand spindle and the smaller diameter on the left hand. These can be easily changed by sliding the sleeve off of the drum and turning it around.

The larger diameter hole of the drum goes onto the spindle first. The mounting bolt with washer goes through and threads into the spindle end. Note that the threads on the left hand spindle are LEFT HAND threads. See Figure 5 for typical installation. Finish the installation by mounting the red end cap on the end of the bolt.

G8749 Drum/Flap Sander

Figure 5. Attaching inflatable drum.

The Sanding Drums need to be inflated in order to retain the abrasive sleeve. It is best to inflate with a hand pump rather than an air compressor. Maximum inflation should never exceed 10 PSI. Inflate slightly less if doing a contour where a little bit of flexibility of the sleeve is required. Figure 6 shows checking the inflation pressure with a good quality gauge.

Figure 6. Checking inflation pressure.

Do not use a compressor to inflate the pneu- matic sanding drum. Use a