3.Turn the upper wheel clockwise by hand and watch the blade ride on the wheels. If the bottom of the blade gullets are not approxi- mately 1⁄16 " away from the edge of the wheels then you need to adjust the tracking handwheel on the backside of the saw.

4.Turn the tracking handwheel a few times and note the direction that the blade shifts when you spin it by hand.

5.Adjust the tracking handwheel until the blade gullets ride approximately 1⁄16" away from the edge of the wheels while you are spinning the upper wheel by hand. Your saw is now properly tracked.

To adjust the support bearings behind the blade:

1.Loosen the hex bolt that secures the support bearing shaft in place.

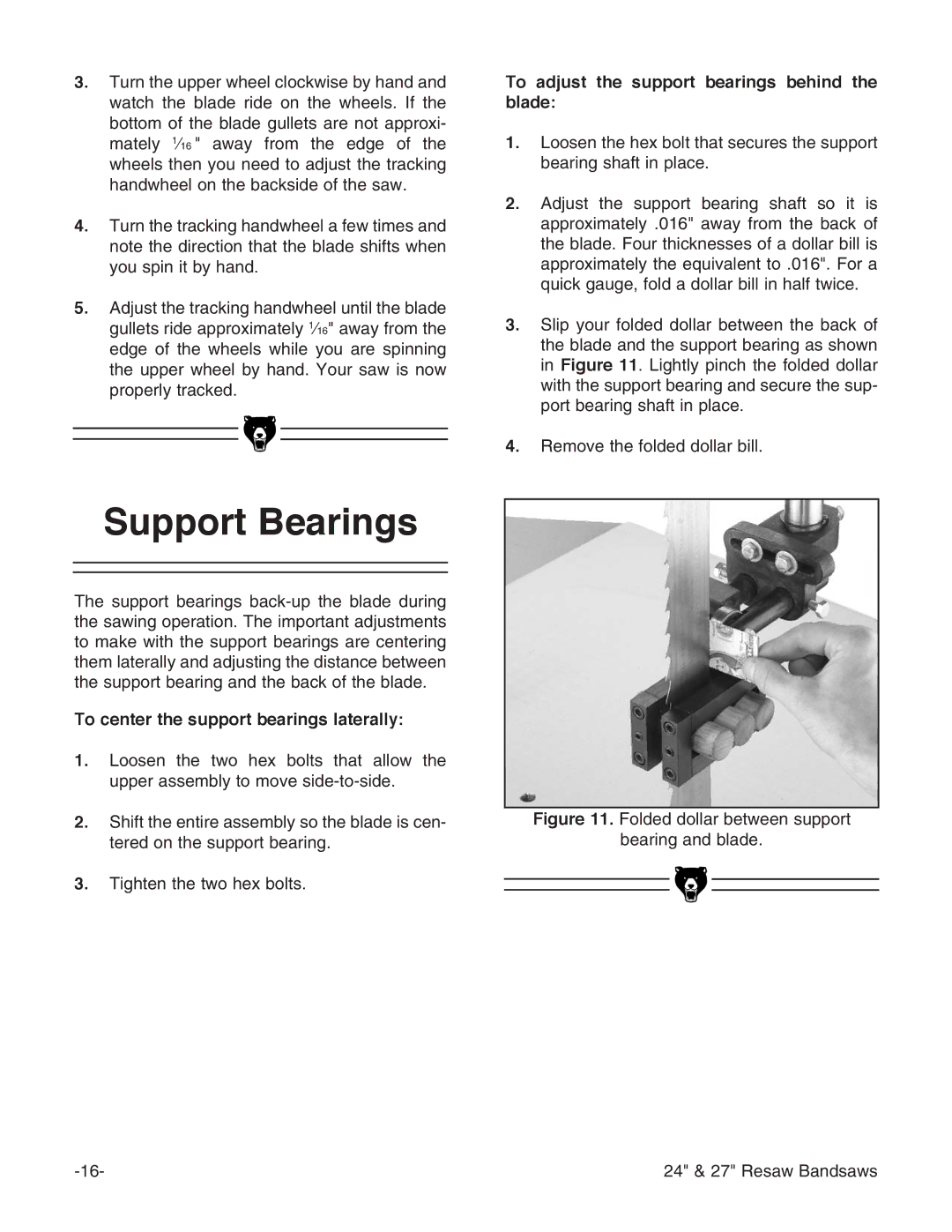

2.Adjust the support bearing shaft so it is approximately .016" away from the back of the blade. Four thicknesses of a dollar bill is approximately the equivalent to .016". For a quick gauge, fold a dollar bill in half twice.

3.Slip your folded dollar between the back of the blade and the support bearing as shown in Figure 11. Lightly pinch the folded dollar with the support bearing and secure the sup- port bearing shaft in place.

4.Remove the folded dollar bill.

Support Bearings

The support bearings

To center the support bearings laterally:

1.Loosen the two hex bolts that allow the upper assembly to move

2.Shift the entire assembly so the blade is cen- tered on the support bearing.

3.Tighten the two hex bolts.

Figure 11. Folded dollar between support

bearing and blade.

24" & 27" Resaw Bandsaws |