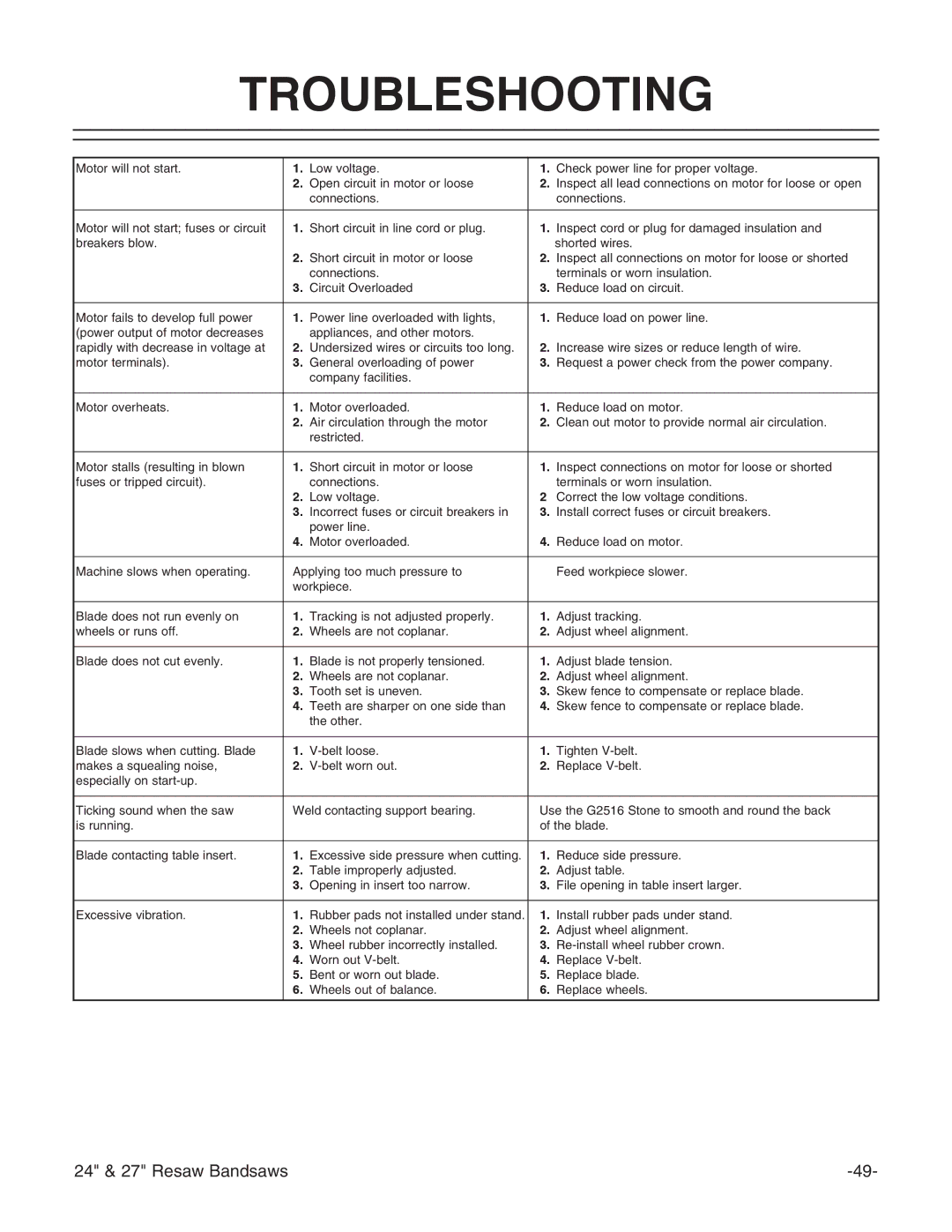

TROUBLESHOOTING

Motor will not start. | 1. | Low voltage. | 1. | Check power line for proper voltage. |

| 2. | Open circuit in motor or loose | 2. | Inspect all lead connections on motor for loose or open |

|

| connections. |

| connections. |

|

|

|

|

|

Motor will not start; fuses or circuit | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and |

breakers blow. |

|

|

| shorted wires. |

| 2. | Short circuit in motor or loose | 2. | Inspect all connections on motor for loose or shorted |

|

| connections. |

| terminals or worn insulation. |

| 3. | Circuit Overloaded | 3. | Reduce load on circuit. |

|

|

|

|

|

Motor fails to develop full power | 1. | Power line overloaded with lights, | 1. | Reduce load on power line. |

(power output of motor decreases |

| appliances, and other motors. |

|

|

rapidly with decrease in voltage at | 2. | Undersized wires or circuits too long. | 2. | Increase wire sizes or reduce length of wire. |

motor terminals). | 3. | General overloading of power | 3. | Request a power check from the power company. |

|

| company facilities. |

|

|

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

| restricted. |

|

|

|

|

|

|

|

Motor stalls (resulting in blown | 1. | Short circuit in motor or loose | 1. | Inspect connections on motor for loose or shorted |

fuses or tripped circuit). |

| connections. |

| terminals or worn insulation. |

| 2. | Low voltage. | 2 | Correct the low voltage conditions. |

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. |

|

| power line. |

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. |

|

|

|

| |

Machine slows when operating. | Applying too much pressure to |

| Feed workpiece slower. | |

| workpiece. |

|

| |

|

|

|

|

|

Blade does not run evenly on | 1. | Tracking is not adjusted properly. | 1. | Adjust tracking. |

wheels or runs off. | 2. | Wheels are not coplanar. | 2. | Adjust wheel alignment. |

|

|

|

|

|

Blade does not cut evenly. | 1. | Blade is not properly tensioned. | 1. | Adjust blade tension. |

| 2. | Wheels are not coplanar. | 2. | Adjust wheel alignment. |

| 3. | Tooth set is uneven. | 3. | Skew fence to compensate or replace blade. |

| 4. | Teeth are sharper on one side than | 4. | Skew fence to compensate or replace blade. |

|

| the other. |

|

|

|

|

|

|

|

Blade slows when cutting. Blade | 1. | 1. | Tighten | |

makes a squealing noise, | 2. | 2. | Replace | |

especially on |

|

|

|

|

|

|

| ||

Ticking sound when the saw | Weld contacting support bearing. | Use the G2516 Stone to smooth and round the back | ||

is running. |

|

| of the blade. | |

|

|

|

|

|

Blade contacting table insert. | 1. | Excessive side pressure when cutting. | 1. | Reduce side pressure. |

| 2. | Table improperly adjusted. | 2. | Adjust table. |

| 3. | Opening in insert too narrow. | 3. | File opening in table insert larger. |

|

|

|

|

|

Excessive vibration. | 1. | Rubber pads not installed under stand. | 1. | Install rubber pads under stand. |

| 2. | Wheels not coplanar. | 2. | Adjust wheel alignment. |

| 3. | Wheel rubber incorrectly installed. | 3. | |

| 4. | Worn out | 4. | Replace |

| 5. | Bent or worn out blade. | 5. | Replace blade. |

| 6. | Wheels out of balance. | 6. | Replace wheels. |

|

|

|

|

|

24" & 27" Resaw Bandsaws |