AIR CONTROL

Delivered Pressure |

| Air Release |

|

|

|

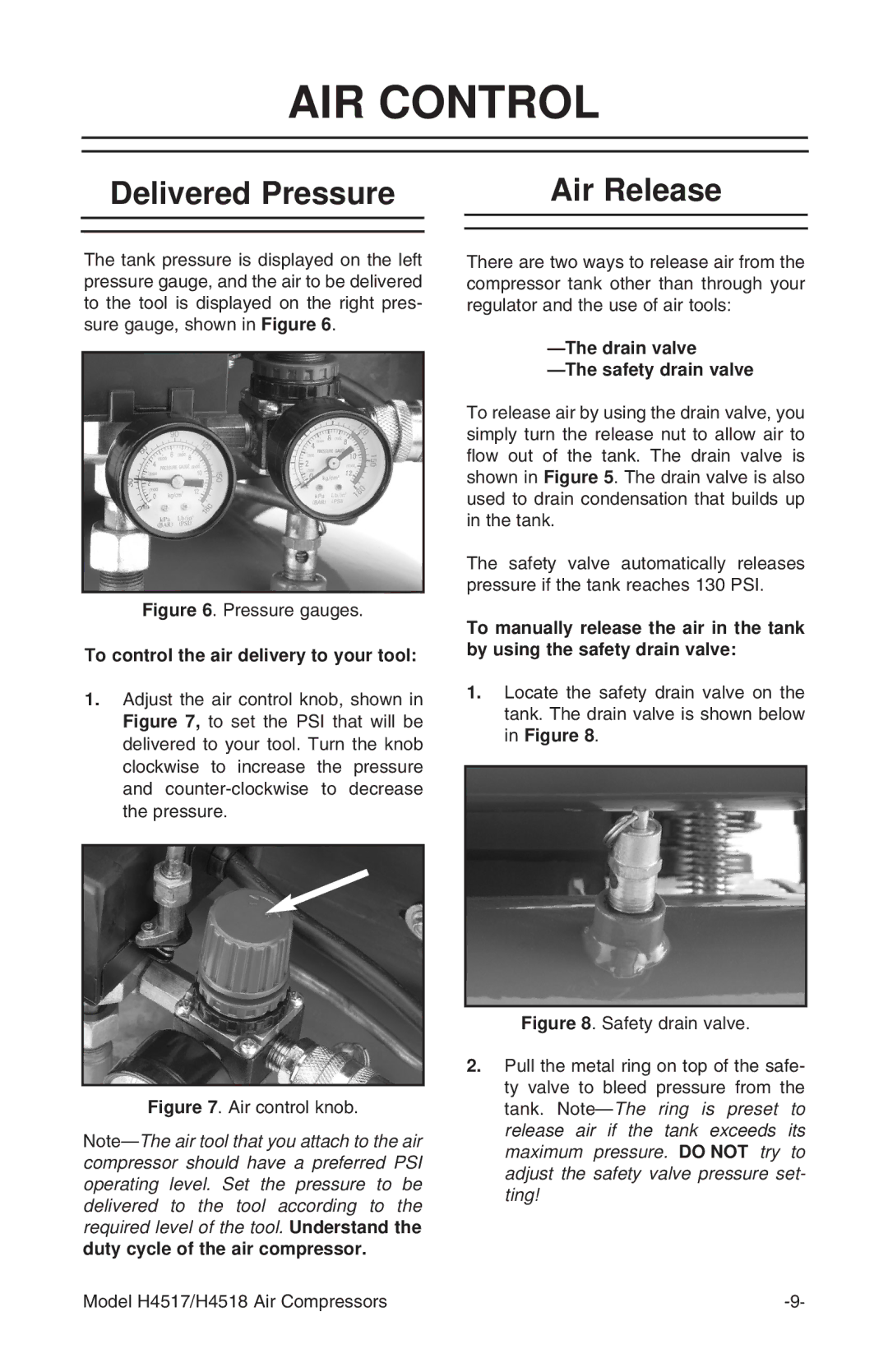

The tank pressure is displayed on the left pressure gauge, and the air to be delivered to the tool is displayed on the right pres- sure gauge, shown in Figure 6.

Figure 6. Pressure gauges.

To control the air delivery to your tool:

1.Adjust the air control knob, shown in Figure 7, to set the PSI that will be delivered to your tool. Turn the knob clockwise to increase the pressure and

Figure 7. Air control knob.

There are two ways to release air from the compressor tank other than through your regulator and the use of air tools:

To release air by using the drain valve, you simply turn the release nut to allow air to flow out of the tank. The drain valve is shown in Figure 5. The drain valve is also used to drain condensation that builds up in the tank.

The safety valve automatically releases pressure if the tank reaches 130 PSI.

To manually release the air in the tank by using the safety drain valve:

1.Locate the safety drain valve on the tank. The drain valve is shown below in Figure 8.

Figure 8. Safety drain valve.

2.Pull the metal ring on top of the safe- ty valve to bleed pressure from the tank. Note—The ring is preset to release air if the tank exceeds its maximum pressure. DO NOT try to adjust the safety valve pressure set- ting!

Model H4517/H4518 Air Compressors |