PREPARING FOR USE

Before using your Grizzly Air Compressor, follow these steps:

1.Remove all packing materials and any protective plastic bags, zip tie labels or tags from the compressor.

2.Be sure the air filter is attached to the cylinder head as shown in Figure 2.

Figure 2. Air filter attached to

cylinder hear.

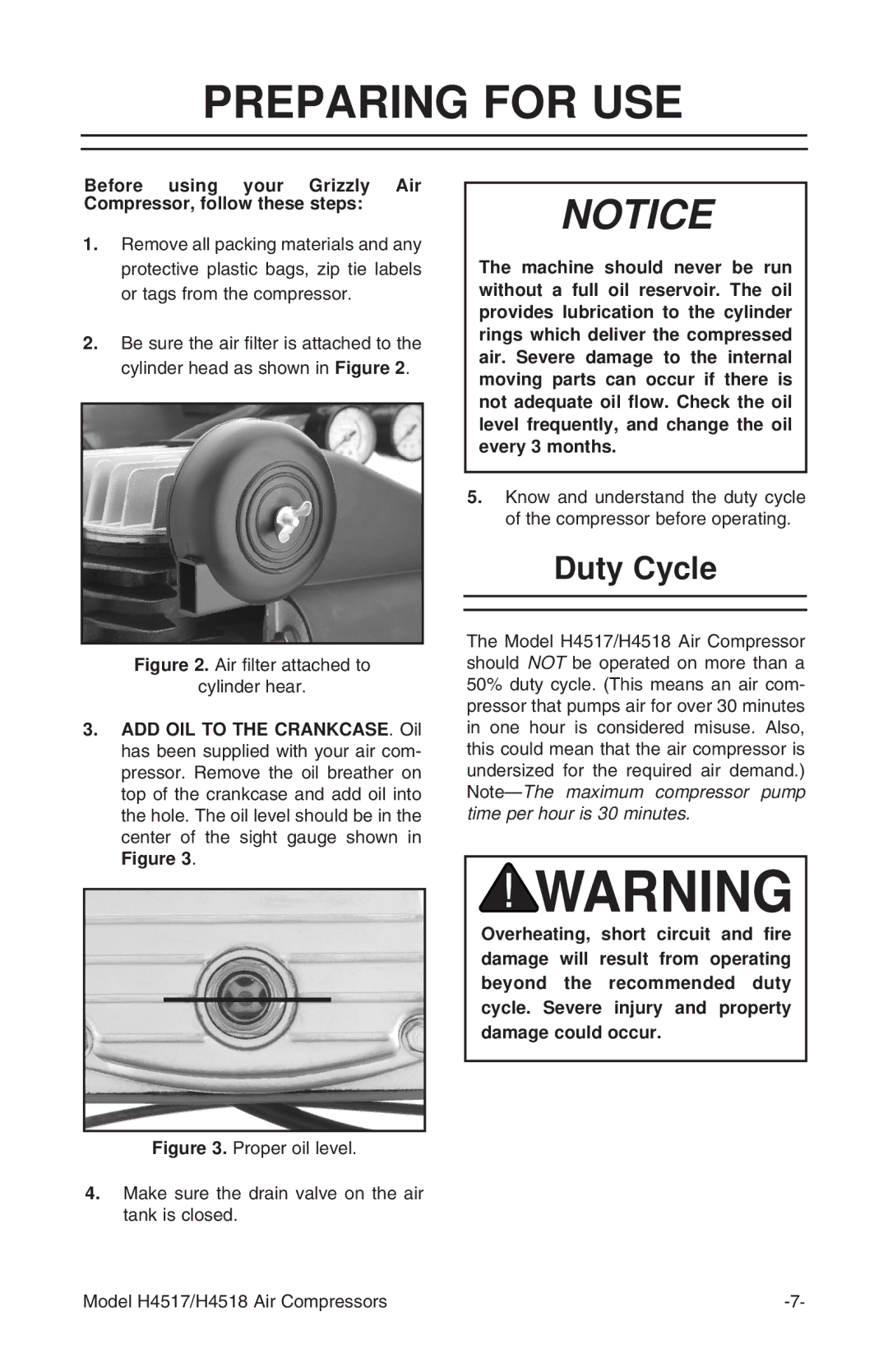

3.ADD OIL TO THE CRANKCASE. Oil has been supplied with your air com- pressor. Remove the oil breather on top of the crankcase and add oil into the hole. The oil level should be in the center of the sight gauge shown in Figure 3.

Figure 3. Proper oil level.

4.Make sure the drain valve on the air tank is closed.

NOTICE

The machine should never be run without a full oil reservoir. The oil provides lubrication to the cylinder rings which deliver the compressed air. Severe damage to the internal moving parts can occur if there is not adequate oil flow. Check the oil level frequently, and change the oil every 3 months.

5.Know and understand the duty cycle of the compressor before operating.

Duty Cycle

The Model H4517/H4518 Air Compressor should NOT be operated on more than a 50% duty cycle. (This means an air com- pressor that pumps air for over 30 minutes in one hour is considered misuse. Also, this could mean that the air compressor is undersized for the required air demand.)

Overheating, short circuit and fire damage will result from operating beyond the recommended duty cycle. Severe injury and property damage could occur.

Model H4517/H4518 Air Compressors |