Using the Grinder

Always test the tooling bit on a scrap piece of material similar to the workpiece. Trial and error is the best way to determine the ideal setup.

To use the grinder:

1.Attach the 1/4" NPT male quick connect fitting to the air inlet plug.

2.Attach the grinder to an air supply set at 90 PSI.

3.Hold the grinder securely.

4.Using the trigger to control RPM, ease the working end of the bit against the workpiece with a light, but steady, pres- sure.

To avoid accidental starting, disconnect the grinder from the air supply when it is not in use.

Daily Maintenance

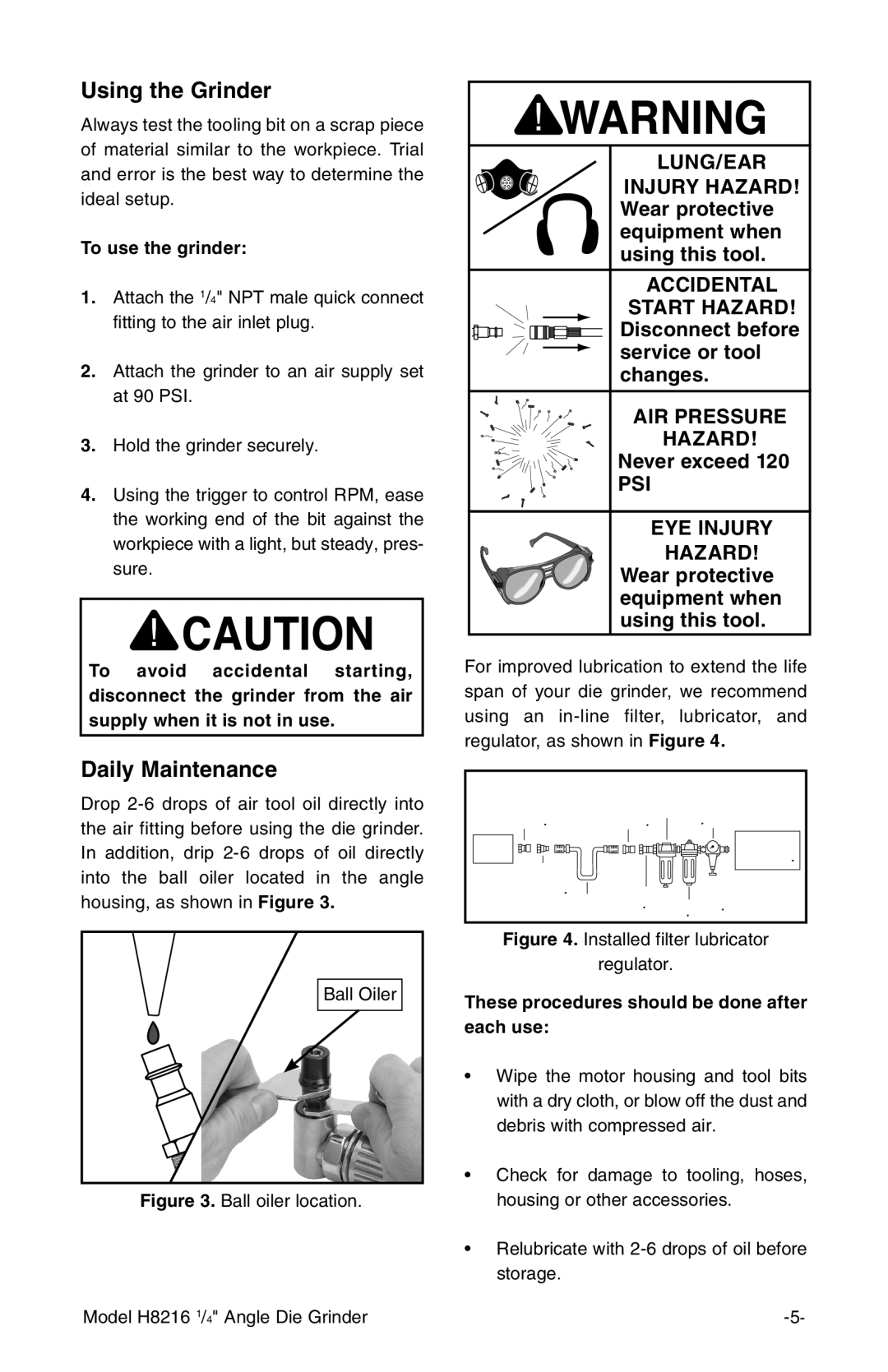

Drop

Ball Oiler

Figure 3. Ball oiler location.

Model H8216 1/4" Angle Die Grinder

LUNG/EAR |

INJURY HAZARD! |

Wear protective |

equipment when |

using this tool. |

ACCIDENTAL |

START HAZARD! |

Disconnect before |

service or tool |

changes. |

AIR PRESSURE |

HAZARD! |

Never exceed 120 |

PSI |

EYE INJURY |

HAZARD! |

Wear protective |

equipment when |

using this tool. |

For improved lubrication to extend the life span of your die grinder, we recommend using an

Quick | Quick | Lubricator | |

Connector | Connector | Regulator | |

Your |

|

| Air |

Tool |

|

| Compressor |

Quick |

|

|

|

Coupler |

| Quick |

|

| Air Hose | Filter | |

| Coupler | ||

|

| ||

Figure 4. Installed filter lubricator

regulator.

These procedures should be done after each use:

•Wipe the motor housing and tool bits with a dry cloth, or blow off the dust and debris with compressed air.

•Check for damage to tooling, hoses, housing or other accessories.

•Relubricate with