To assemble the jig for hollow chisels:

1.Completely disassemble the chisel sharpen- ing jig as shown in Figure 5.

2.

Chisel Sharpening Jig

Figure 9. Hollow chisel jig assembly.

To sharpen hollow chisels:

1.DISCONNECT GRINDER FROM POWER!

2.Place the universal support in either the verti- cal or horizontal mounts, depending on the desired grinding action as described in the Model T10010/T10097 owner's manual.

3.Clamp the chisel

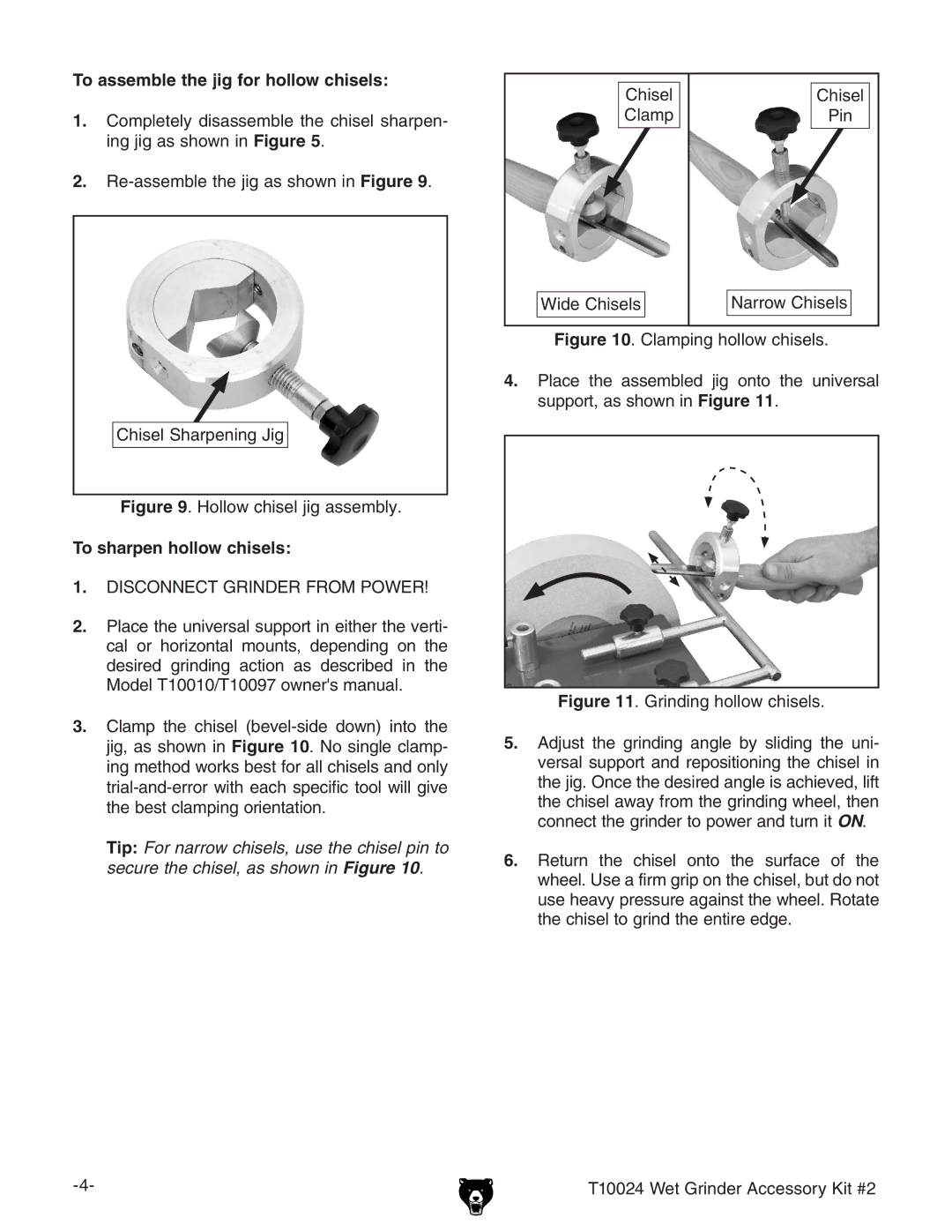

Tip: For narrow chisels, use the chisel pin to secure the chisel, as shown in Figure 10.

Chisel | Chisel |

Clamp | Pin |

Wide Chisels | Narrow Chisels |