Installation

1.DISCONNECT JOINTER FROM POWER!

2.Remove the jointer fence and cutterhead guard.

3.Remove the

4.Lower both beds to make enough room for the cutterhead to come out, as shown in

Figure 3.

Note: When lowering, make sure that the fence support does not come in contact with the cutterhead pulley.

Figure 3. Example of jointer disassembly Steps

5.Remove the nut and lock washer on the bear- ing block stud, as shown in Figure 4, and repeat on the other side.

Figure 4. Example of removing nut and lock

washer on bearing block stud.

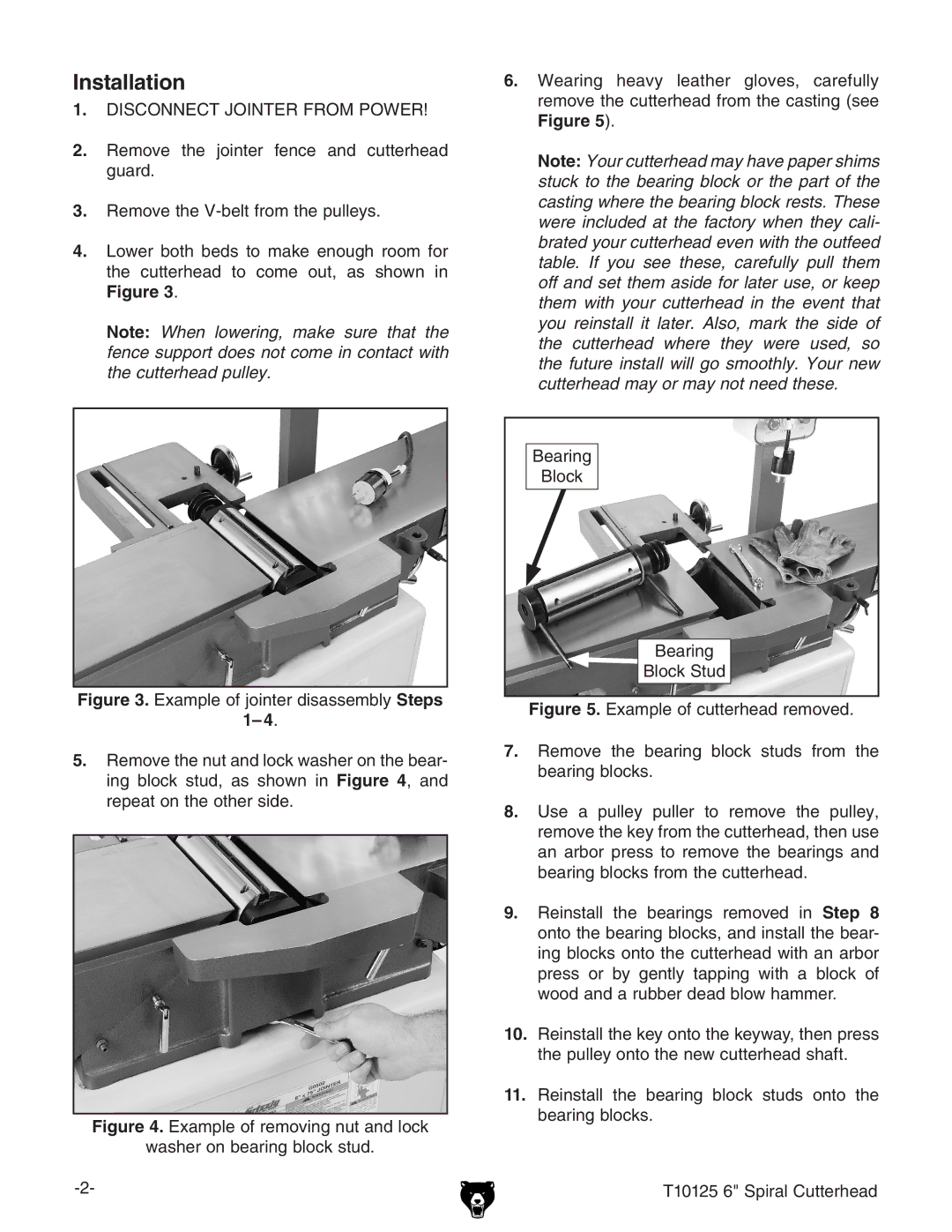

6.Wearing heavy leather gloves, carefully remove the cutterhead from the casting (see

Figure 5).

Note: Your cutterhead may have paper shims stuck to the bearing block or the part of the casting where the bearing block rests. These were included at the factory when they cali- brated your cutterhead even with the outfeed table. If you see these, carefully pull them off and set them aside for later use, or keep them with your cutterhead in the event that you reinstall it later. Also, mark the side of the cutterhead where they were used, so the future install will go smoothly. Your new cutterhead may or may not need these.

Bearing

Block

Bearing