Groove Cutting

Groove cutting produces a groove or bead into the face of the board.

To cut a groove into the face of the workpiece:

1.DISCONNECT ROUTER FROM POWER!

2.Secure the bit into the router according to the router manufacturer's instructions.

3.Install the smallest table insert into the table that still allows the bit to freely rotate.

4.Make sure both fence boards are even with one another and secured to the fence assem- bly.

5.Raise the bit to the desired height, then adjust the fence assembly so that the fence boards are behind the bit the same distance as the desired

Figures 23–24).

Top View |

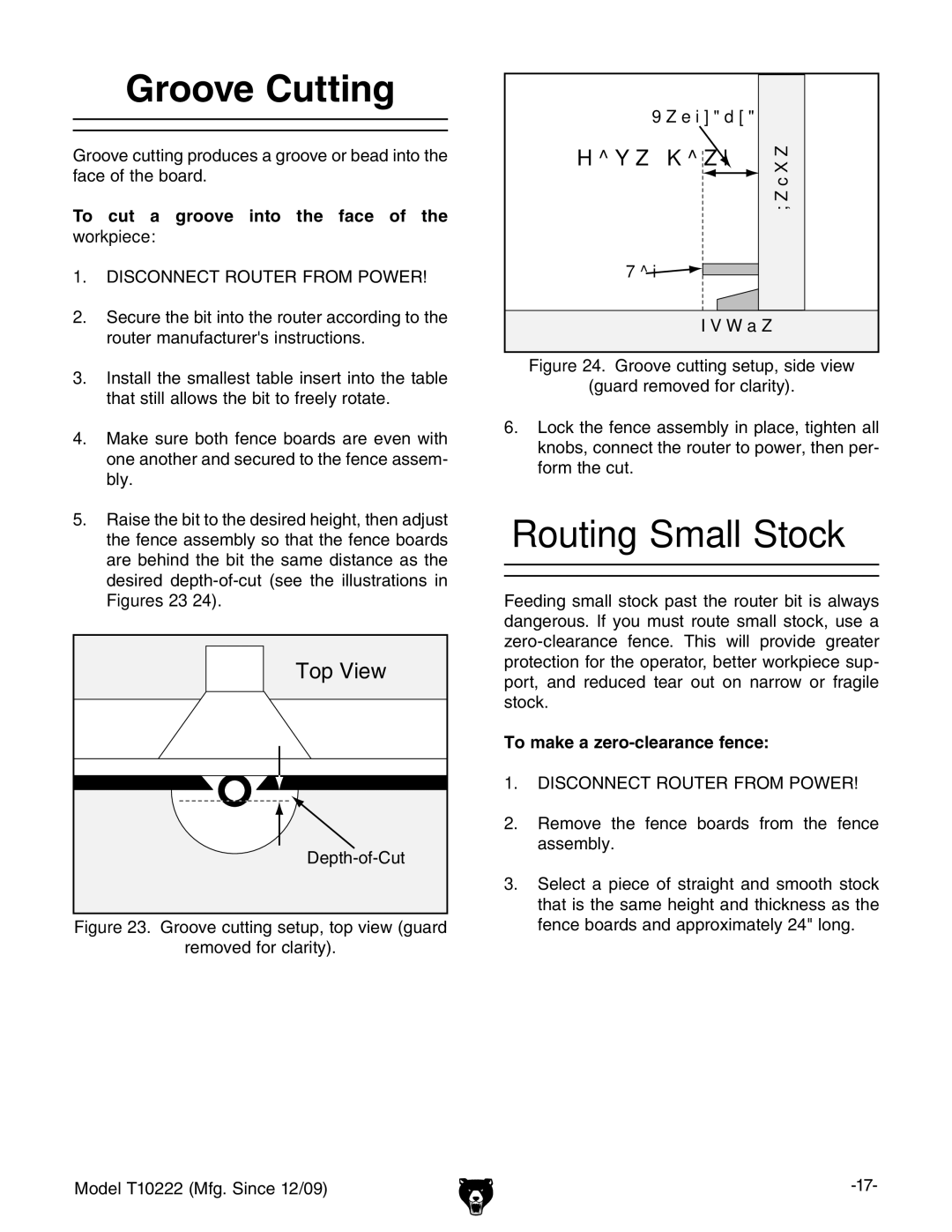

Figure 23. Groove cutting setup, top view (guard

removed for clarity).

Depth-of-Cut

Side View

Fence

Bit ![]()

Table

Figure 24. Groove cutting setup, side view

(guard removed for clarity).

6.Lock the fence assembly in place, tighten all knobs, connect the router to power, then per- form the cut.

Routing Small Stock

Feeding small stock past the router bit is always dangerous. If you must route small stock, use a

To make a zero-clearance fence:

1.DISCONNECT ROUTER FROM POWER!

2.Remove the fence boards from the fence assembly.

3.Select a piece of straight and smooth stock that is the same height and thickness as the fence boards and approximately 24" long.

Model T10222 (Mfg. Since 12/09) |