4.Cut an outline of the spindle and cutter from the center of the stock selected in Step 3, as illustrated in Figure 25.

Note: Make the outline as close as possible to the cutter and spindle without interfering with rotation.

Mounting |

Fastener |

Table |

Cutter |

Figure 25. Example of a zero-clearance fence.

5.Create countersunk mounting holes in the zero-clearance fence so that the screws and T-nuts removed from the split fence can be used to secure the new fence to the fence assembly in the same manner.

ALWAYS use

6.Secure the

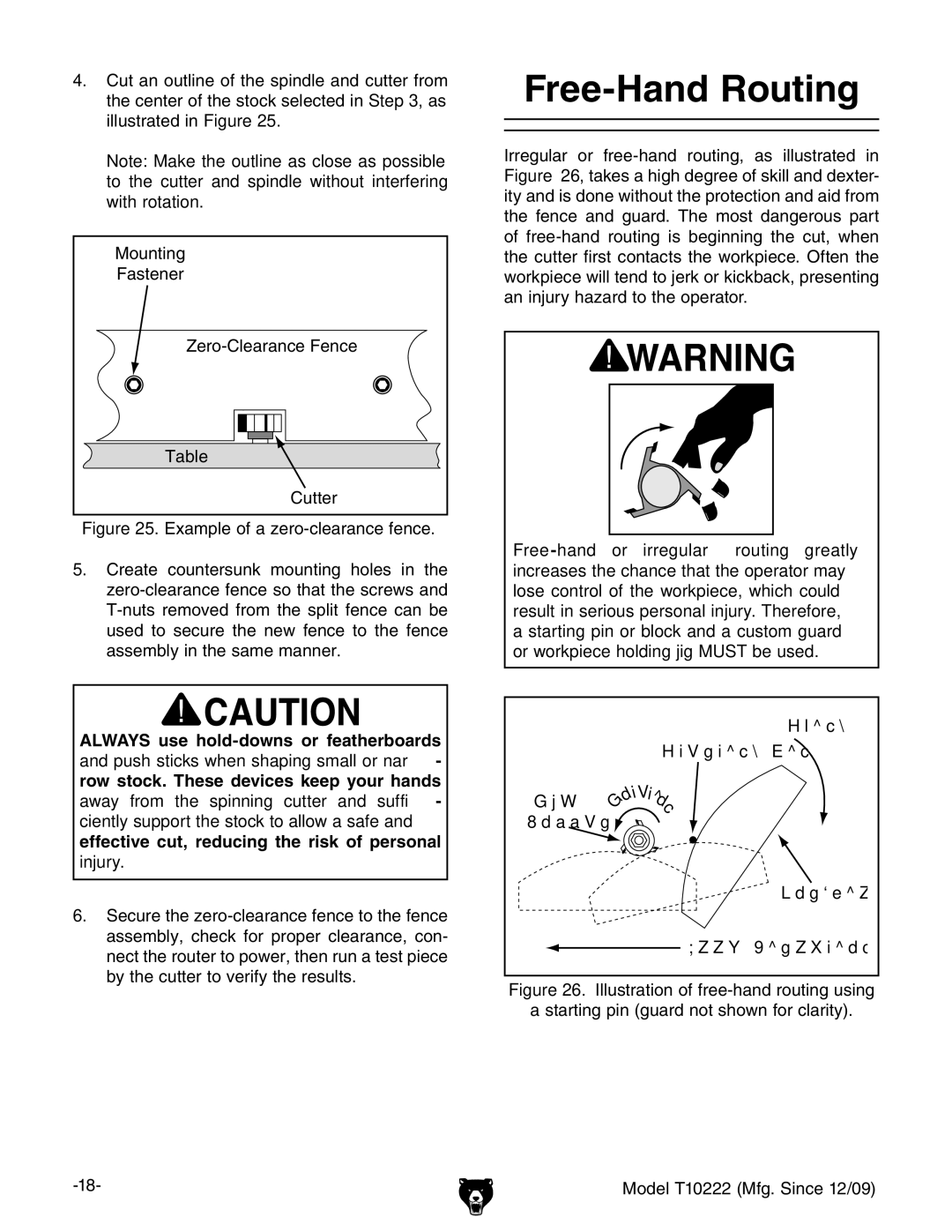

Free-Hand Routing

Irregular or

|

|

|

|

| Swing |

|

|

|

|

| Starting Pin |

|

| t | a |

|

|

|

| ti |

| ||

Rub | o |

| o | ||

R |

|

|

| n | |

Collar |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| Workpiece |

|

|

|

|

| Feed Direction |

Figure 26. Illustration of free-hand routing using

a starting pin (guard not shown for clarity).

Model T10222 (Mfg. Since 12/09) |