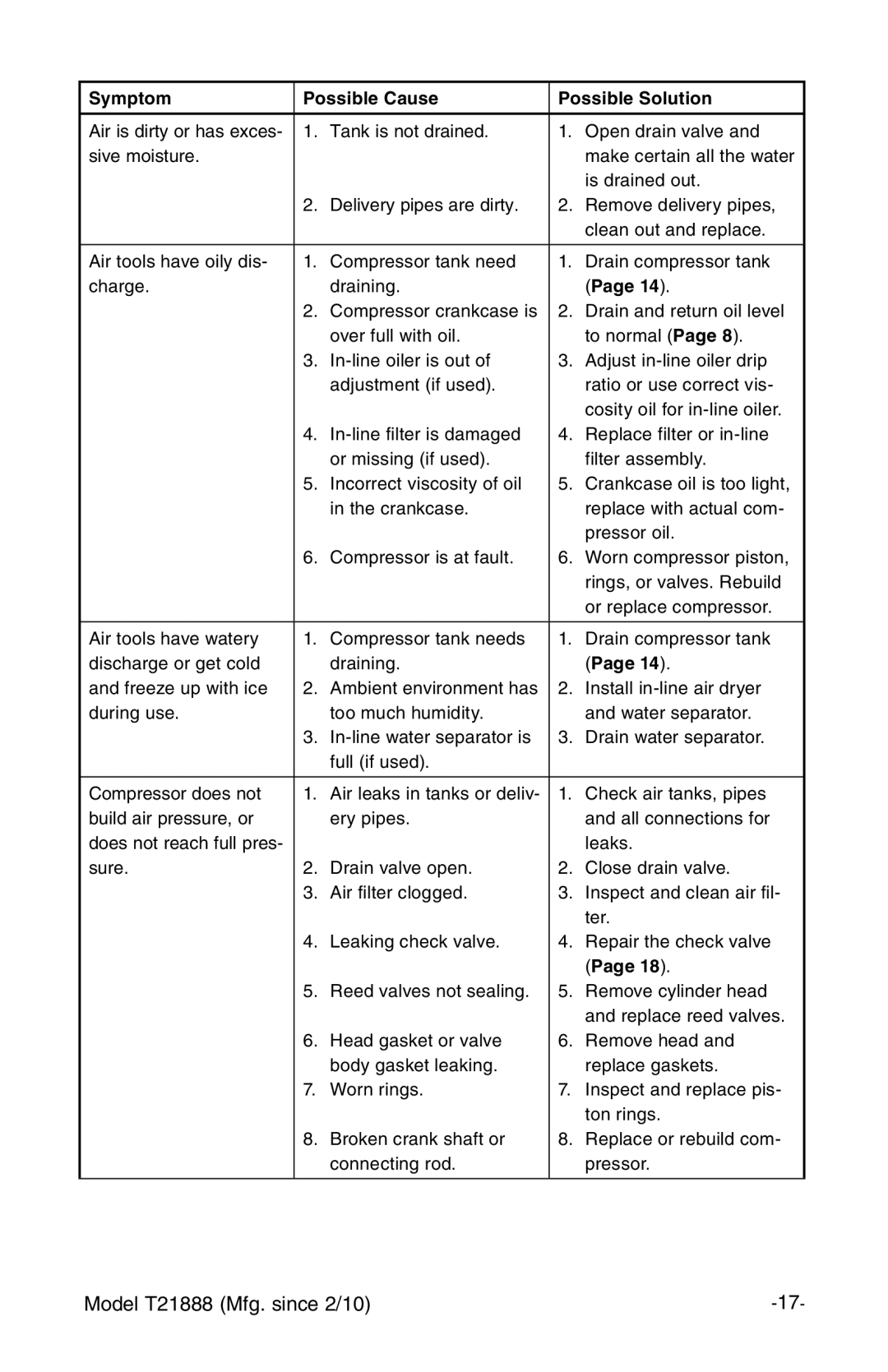

Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

Air is dirty or has exces- | 1. | Tank is not drained. | 1. | Open drain valve and |

sive moisture. |

|

|

| make certain all the water |

|

|

|

| is drained out. |

| 2. | Delivery pipes are dirty. | 2. | Remove delivery pipes, |

|

|

|

| clean out and replace. |

|

|

|

|

|

Air tools have oily dis- | 1. | Compressor tank need | 1. | Drain compressor tank |

charge. |

| draining. |

| (Page 14). |

| 2. | Compressor crankcase is | 2. | Drain and return oil level |

|

| over full with oil. |

| to normal (Page 8). |

| 3. | 3. | Adjust | |

|

| adjustment (if used). |

| ratio or use correct vis- |

|

|

|

| cosity oil for |

| 4. | 4. | Replace filter or | |

|

| or missing (if used). |

| filter assembly. |

| 5. | Incorrect viscosity of oil | 5. | Crankcase oil is too light, |

|

| in the crankcase. |

| replace with actual com- |

|

|

|

| pressor oil. |

| 6. | Compressor is at fault. | 6. | Worn compressor piston, |

|

|

|

| rings, or valves. Rebuild |

|

|

|

| or replace compressor. |

|

|

|

|

|

Air tools have watery | 1. | Compressor tank needs | 1. | Drain compressor tank |

discharge or get cold |

| draining. |

| (Page 14). |

and freeze up with ice | 2. | Ambient environment has | 2. | Install |

during use. |

| too much humidity. |

| and water separator. |

| 3. | 3. | Drain water separator. | |

|

| full (if used). |

|

|

|

|

|

|

|

Compressor does not | 1. | Air leaks in tanks or deliv- | 1. | Check air tanks, pipes |

build air pressure, or |

| ery pipes. |

| and all connections for |

does not reach full pres- |

|

|

| leaks. |

sure. | 2. | Drain valve open. | 2. | Close drain valve. |

| 3. | Air filter clogged. | 3. | Inspect and clean air fil- |

|

|

|

| ter. |

| 4. | Leaking check valve. | 4. | Repair the check valve |

|

|

|

| (Page 18). |

| 5. | Reed valves not sealing. | 5. | Remove cylinder head |

|

|

|

| and replace reed valves. |

| 6. | Head gasket or valve | 6. | Remove head and |

|

| body gasket leaking. |

| replace gaskets. |

| 7. | Worn rings. | 7. | Inspect and replace pis- |

|

|

|

| ton rings. |

| 8. | Broken crank shaft or | 8. | Replace or rebuild com- |

|

| connecting rod. |

| pressor. |

|

|

|

|

|

Model T21888 (Mfg. since 2/10) |