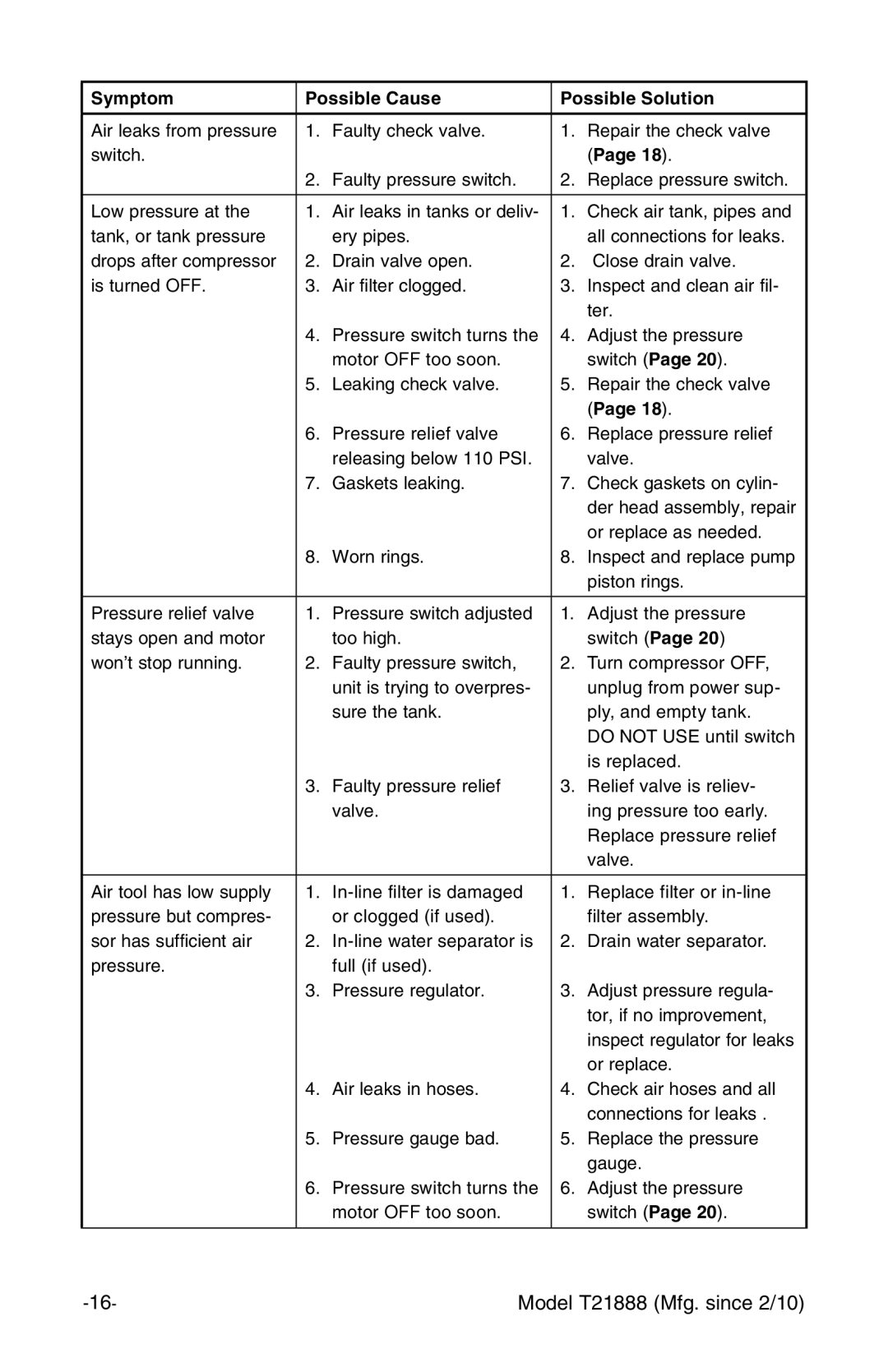

Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

Air leaks from pressure | 1. | Faulty check valve. | 1. | Repair the check valve |

switch. |

|

|

| (Page 18). |

| 2. | Faulty pressure switch. | 2. | Replace pressure switch. |

|

|

|

|

|

Low pressure at the | 1. | Air leaks in tanks or deliv- | 1. | Check air tank, pipes and |

tank, or tank pressure |

| ery pipes. |

| all connections for leaks. |

drops after compressor | 2. | Drain valve open. | 2. | Close drain valve. |

is turned OFF. | 3. | Air filter clogged. | 3. | Inspect and clean air fil- |

|

|

|

| ter. |

| 4. | Pressure switch turns the | 4. | Adjust the pressure |

|

| motor OFF too soon. |

| switch (Page 20). |

| 5. | Leaking check valve. | 5. | Repair the check valve |

|

|

|

| (Page 18). |

| 6. | Pressure relief valve | 6. | Replace pressure relief |

|

| releasing below 110 PSI. |

| valve. |

| 7. | Gaskets leaking. | 7. | Check gaskets on cylin- |

|

|

|

| der head assembly, repair |

|

|

|

| or replace as needed. |

| 8. | Worn rings. | 8. | Inspect and replace pump |

|

|

|

| piston rings. |

|

|

|

|

|

Pressure relief valve | 1. | Pressure switch adjusted | 1. | Adjust the pressure |

stays open and motor |

| too high. |

| switch (Page 20) |

won’t stop running. | 2. | Faulty pressure switch, | 2. | Turn compressor OFF, |

|

| unit is trying to overpres- |

| unplug from power sup- |

|

| sure the tank. |

| ply, and empty tank. |

|

|

|

| DO NOT USE until switch |

|

|

|

| is replaced. |

| 3. | Faulty pressure relief | 3. | Relief valve is reliev- |

|

| valve. |

| ing pressure too early. |

|

|

|

| Replace pressure relief |

|

|

|

| valve. |

|

|

|

|

|

Air tool has low supply | 1. | 1. | Replace filter or | |

pressure but compres- |

| or clogged (if used). |

| filter assembly. |

sor has sufficient air | 2. | 2. | Drain water separator. | |

pressure. |

| full (if used). |

|

|

| 3. | Pressure regulator. | 3. | Adjust pressure regula- |

|

|

|

| tor, if no improvement, |

|

|

|

| inspect regulator for leaks |

|

|

|

| or replace. |

| 4. | Air leaks in hoses. | 4. | Check air hoses and all |

|

|

|

| connections for leaks . |

| 5. | Pressure gauge bad. | 5. | Replace the pressure |

|

|

|

| gauge. |

| 6. | Pressure switch turns the | 6. | Adjust the pressure |

|

| motor OFF too soon. |

| switch (Page 20). |

|

|

|

|

|

Model T21888 (Mfg. since 2/10) |