SECTION 4: OPERATIONS

EYE INJUry HAZARD!

Wear safety glasses when using this tool.

Lung/Ear

InJUry HAZARD! Wear protective equipment when using this tool.

ACCIDENTAL

Start HAZARD! Disconnect before service or staple replacement.

AIR PRESSURE

HAzard!

Never exceed max

Psi rating for tool.

Deflection due to material irregulari- ties can cause puncture injuries to improperly placed hands or body parts. Always position hands and body away from staple trajectory and deflection paths.

The purpose of this overview is to pro- vide the novice tool operator with a basic understanding of how the tool is used.

To perform a typical operation:

1.DISCONNECT STAPLER FROM AIR SUPPLY!

2. Check to ensure there are enough staples in the magazine and reconnect to air supply.

3. drive a staple into a scrap piece of the same material, and inspect the depth of the driven staple.

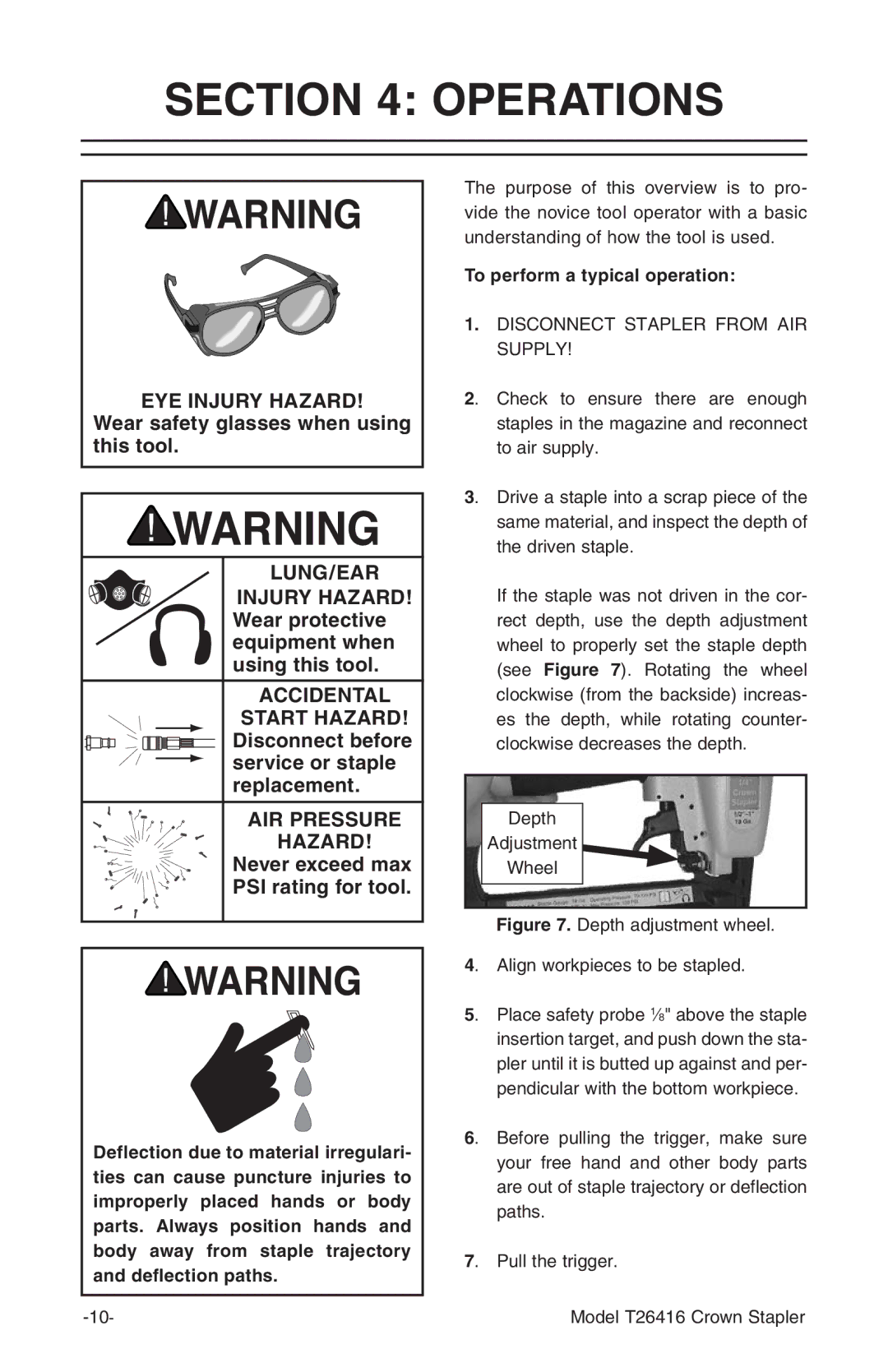

if the staple was not driven in the cor- rect depth, use the depth adjustment wheel to properly set the staple depth (see Figure 7). Rotating the wheel clockwise (from the backside) increas- es the depth, while rotating counter- clockwise decreases the depth.

Depth

Adjustment

Wheel

Figure 7. Depth adjustment wheel.

4. Align workpieces to be stapled.

5. place safety probe 1⁄8" above the staple insertion target, and push down the sta- pler until it is butted up against and per- pendicular with the bottom workpiece.

6. Before pulling the trigger, make sure your free hand and other body parts are out of staple trajectory or deflection paths.

7. Pull the trigger.

Model T26416 Crown Stapler