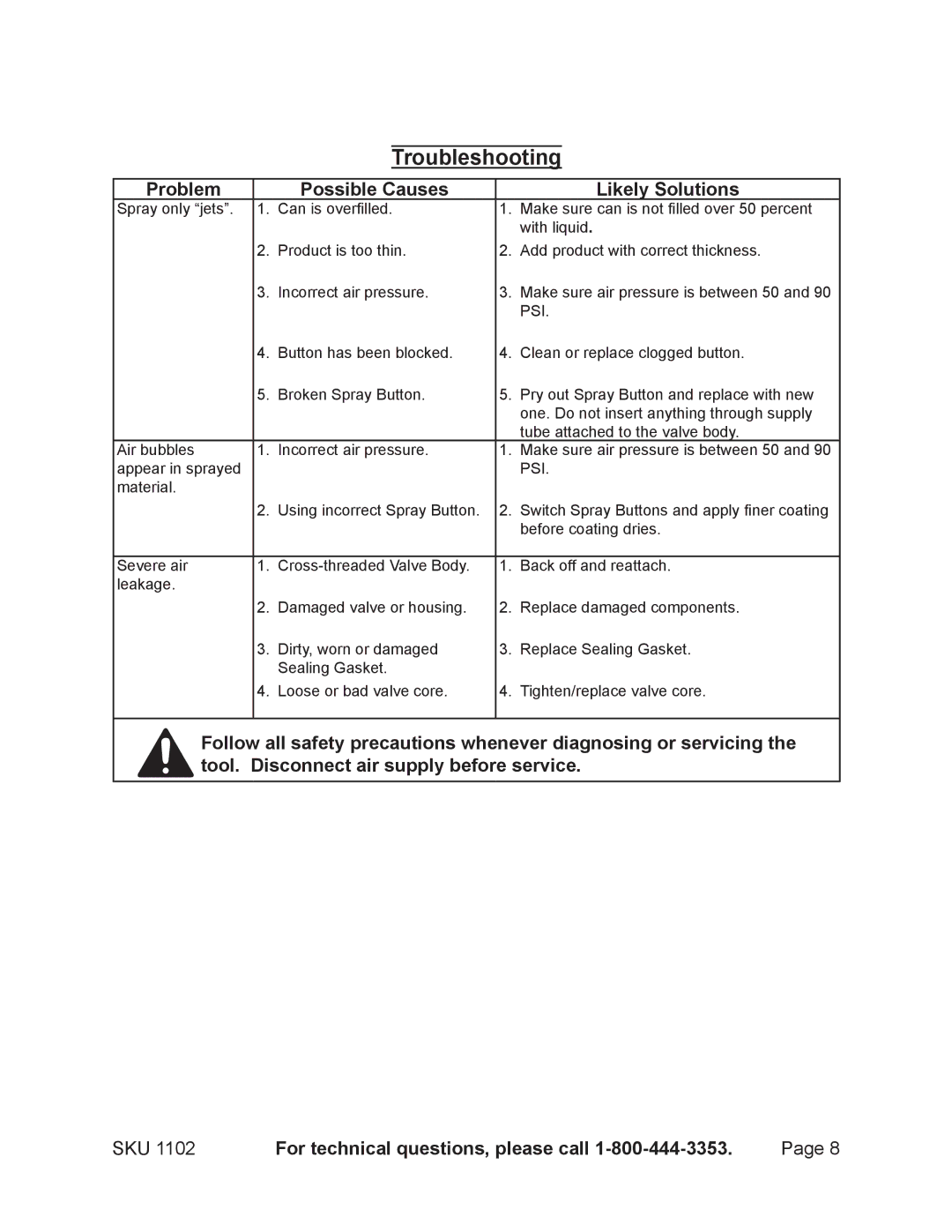

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Spray only “jets”. | 1. | Can is overfilled. | 1. | Make sure can is not filled over 50 percent |

|

|

|

| with liquid. |

| 2. | Product is too thin. | 2. | Add product with correct thickness. |

| 3. | Incorrect air pressure. | 3. | Make sure air pressure is between 50 and 90 |

|

|

|

| PSI. |

| 4. | Button has been blocked. | 4. | Clean or replace clogged button. |

| 5. | Broken Spray Button. | 5. | Pry out Spray Button and replace with new |

|

|

|

| one. Do not insert anything through supply |

|

|

|

| tube attached to the valve body. |

Air bubbles | 1. Incorrect air pressure. | 1. | Make sure air pressure is between 50 and 90 | |

appear in sprayed |

|

|

| PSI. |

material. |

|

|

|

|

2.Using incorrect Spray Button. 2. Switch Spray Buttons and apply finer coating before coating dries.

Severe air | 1. | 1. | Back off and reattach. | |

leakage. |

|

|

|

|

| 2. | Damaged valve or housing. | 2. | Replace damaged components. |

| 3. | Dirty, worn or damaged | 3. | Replace Sealing Gasket. |

|

| Sealing Gasket. |

|

|

| 4. | Loose or bad valve core. | 4. | Tighten/replace valve core. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

SKU 1102 | For technical questions, please call | Page 8 |