Handheld Shaded Face Shield

Assemble the Handheld Shaded Face Shield as illustrated in its Assembly Drawing at the end of this manual.

Operation

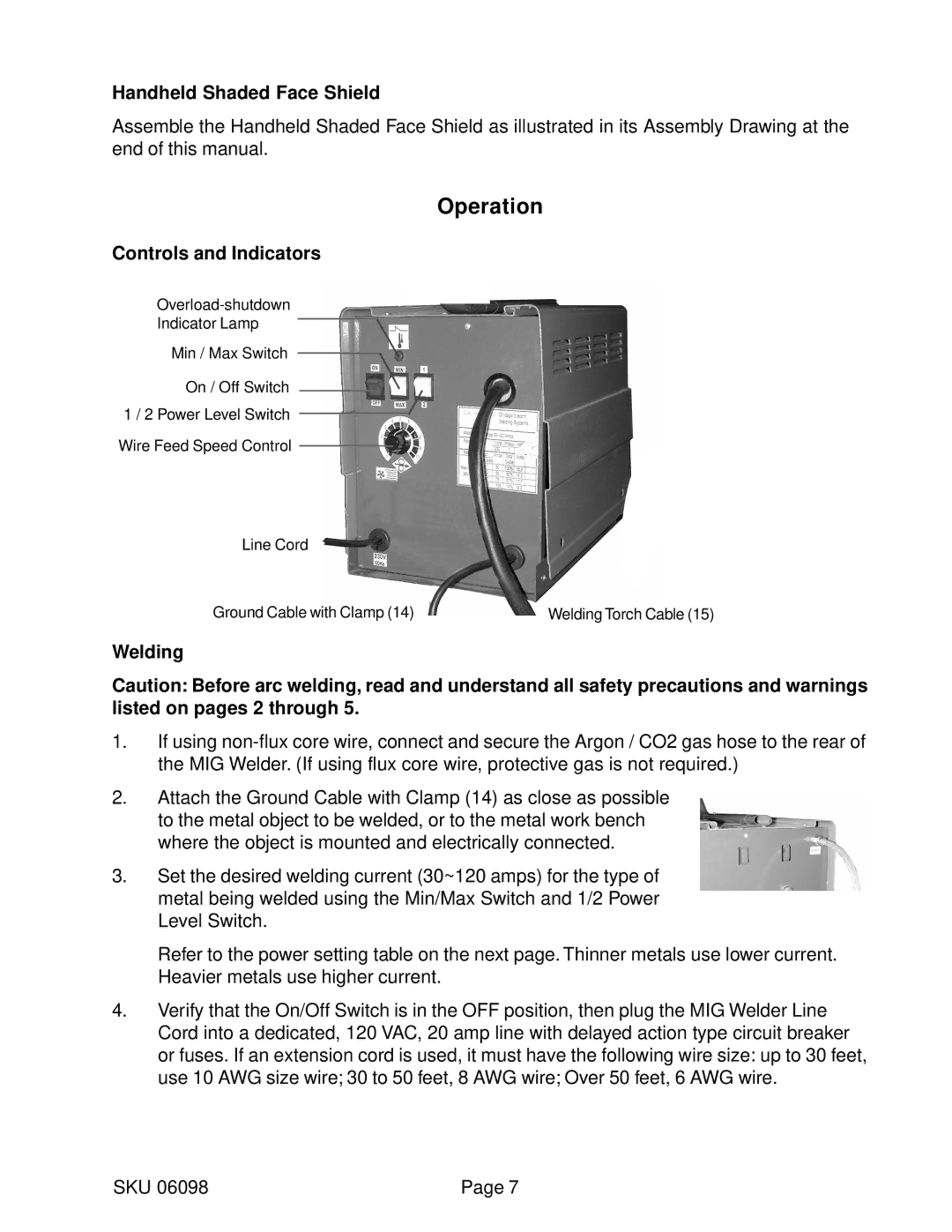

Controls and Indicators

Indicator Lamp

Min / Max Switch

On / Off Switch

1 / 2 Power Level Switch

Wire Feed Speed Control

Line Cord

Ground Cable with Clamp (14) | Welding Torch Cable (15) |

Welding

Caution: Before arc welding, read and understand all safety precautions and warnings listed on pages 2 through 5.

1.If using

2.Attach the Ground Cable with Clamp (14) as close as possible to the metal object to be welded, or to the metal work bench where the object is mounted and electrically connected.

3.Set the desired welding current (30~120 amps) for the type of metal being welded using the Min/Max Switch and 1/2 Power Level Switch.

Refer to the power setting table on the next page. Thinner metals use lower current. Heavier metals use higher current.

4.Verify that the On/Off Switch is in the OFF position, then plug the MIG Welder Line Cord into a dedicated, 120 VAC, 20 amp line with delayed action type circuit breaker or fuses. If an extension cord is used, it must have the following wire size: up to 30 feet, use 10 AWG size wire; 30 to 50 feet, 8 AWG wire; Over 50 feet, 6 AWG wire.

SKU 06098 | Page 7 |