Troubleshooting

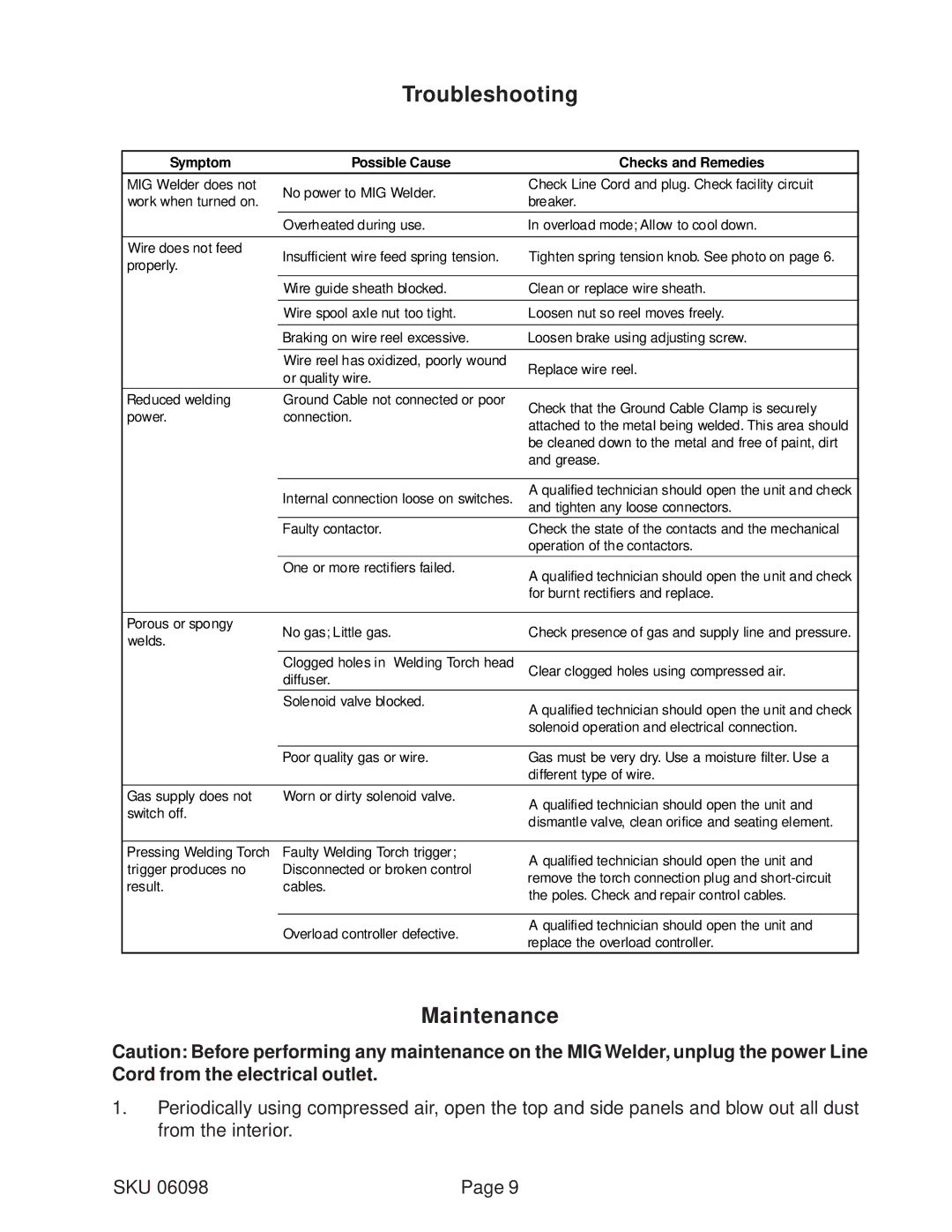

Symptom | Possible Cause | Checks and Remedies | |

|

|

| |

MIG Welder does not | No power to MIG Welder. | Check Line Cord and plug. Check facility circuit | |

work when turned on. | breaker. | ||

| |||

|

|

| |

| Overheated during use. | In overload mode; Allow to cool down. | |

|

|

| |

Wire does not feed | Insufficient wire feed spring tension. | Tighten spring tension knob. See photo on page 6. | |

properly. | |||

|

| ||

|

|

| |

| Wire guide sheath blocked. | Clean or replace wire sheath. | |

|

|

| |

| Wire spool axle nut too tight. | Loosen nut so reel moves freely. | |

|

|

| |

| Braking on wire reel excessive. | Loosen brake using adjusting screw. | |

|

|

| |

| Wire reel has oxidized, poorly wound | Replace wire reel. | |

| or quality wire. | ||

|

| ||

|

|

| |

Reduced welding | Ground Cable not connected or poor | Check that the Ground Cable Clamp is securely | |

power. | connection. | ||

attached to the metal being welded. This area should | |||

|

| ||

|

| be cleaned down to the metal and free of paint, dirt | |

|

| and grease. | |

|

|

| |

| Internal connection loose on switches. | A qualified technician should open the unit and check | |

| and tighten any loose connectors. | ||

|

| ||

|

|

| |

| Faulty contactor. | Check the state of the contacts and the mechanical | |

|

| operation of the contactors. | |

|

|

| |

| One or more rectifiers failed. | A qualified technician should open the unit and check | |

|

| ||

|

| for burnt rectifiers and replace. | |

|

|

| |

Porous or spongy | No gas; Little gas. | Check presence of gas and supply line and pressure. | |

welds. | |||

|

| ||

|

|

| |

| Clogged holes in Welding Torch head | Clear clogged holes using compressed air. | |

| diffuser. | ||

|

| ||

|

|

| |

| Solenoid valve blocked. | A qualified technician should open the unit and check | |

|

| ||

|

| solenoid operation and electrical connection. | |

|

|

| |

| Poor quality gas or wire. | Gas must be very dry. Use a moisture filter. Use a | |

|

| different type of wire. | |

|

|

| |

Gas supply does not | Worn or dirty solenoid valve. | A qualified technician should open the unit and | |

switch off. |

| ||

| dismantle valve, clean orifice and seating element. | ||

|

| ||

|

|

| |

Pressing Welding Torch | Faulty Welding Torch trigger; | A qualified technician should open the unit and | |

trigger produces no | Disconnected or broken control | ||

remove the torch connection plug and | |||

result. | cables. | ||

the poles. Check and repair control cables. | |||

|

| ||

|

|

| |

| Overload controller defective. | A qualified technician should open the unit and | |

| replace the overload controller. | ||

|

|

Maintenance

Caution: Before performing any maintenance on the MIG Welder, unplug the power Line Cord from the electrical outlet.

1.Periodically using compressed air, open the top and side panels and blow out all dust from the interior.

SKU 06098 | Page 9 |