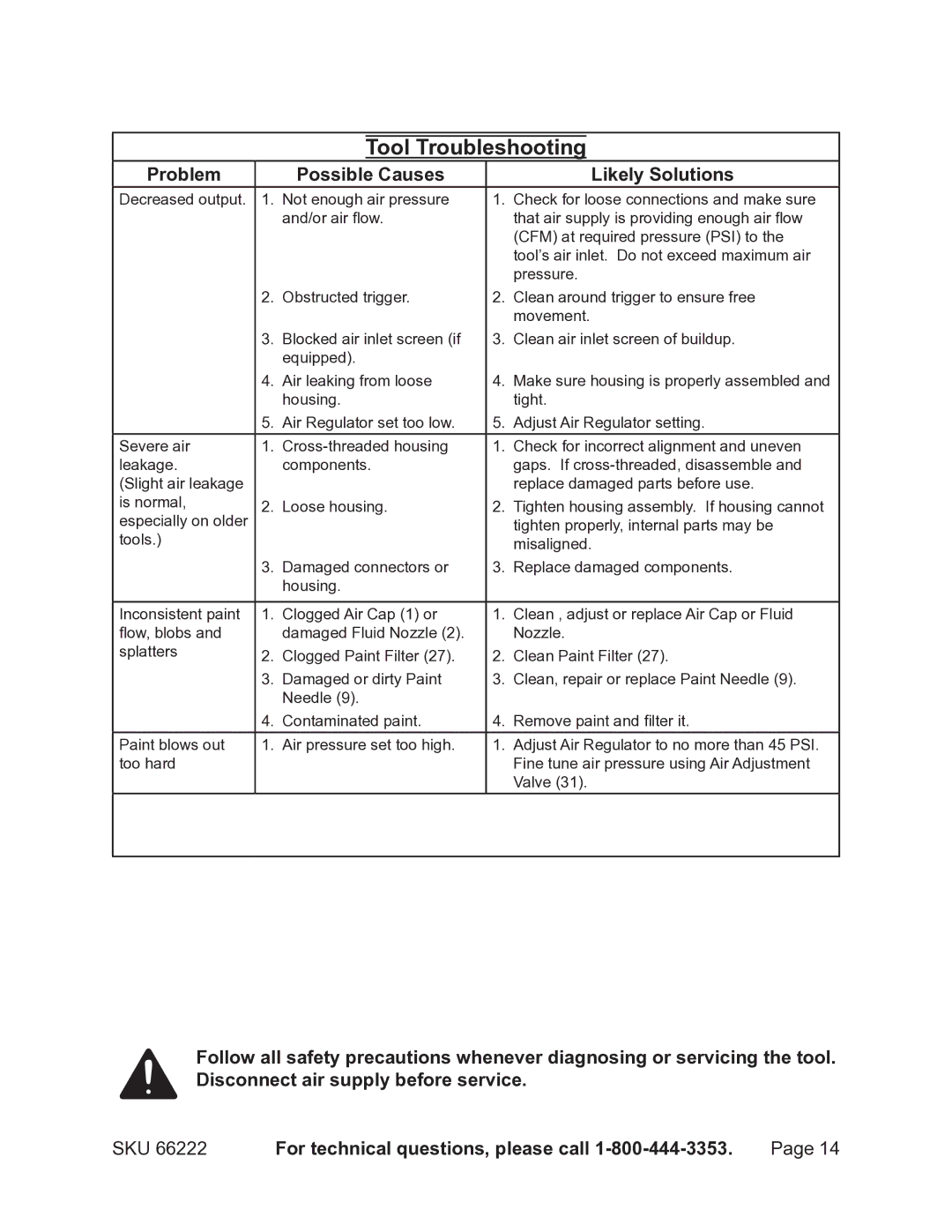

Tool Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Decreased output. | 1. Not enough air pressure | 1. | Check for loose connections and make sure | |

|

| and/or air flow. |

| that air supply is providing enough air flow |

|

|

|

| (CFM) at required pressure (PSI) to the |

|

|

|

| tool’s air inlet. Do not exceed maximum air |

|

|

|

| pressure. |

| 2. | Obstructed trigger. | 2. | Clean around trigger to ensure free |

|

|

|

| movement. |

| 3. | Blocked air inlet screen (if | 3. | Clean air inlet screen of buildup. |

|

| equipped). |

|

|

| 4. | Air leaking from loose | 4. | Make sure housing is properly assembled and |

|

| housing. |

| tight. |

| 5. | Air Regulator set too low. | 5. | Adjust Air Regulator setting. |

Severe air | 1. | 1. | Check for incorrect alignment and uneven | |

leakage. |

| components. |

| gaps. If |

(Slight air leakage |

|

|

| replace damaged parts before use. |

is normal, | 2. Loose housing. | 2. | Tighten housing assembly. If housing cannot | |

especially on older |

|

|

| tighten properly, internal parts may be |

tools.) |

|

|

| misaligned. |

| 3. | Damaged connectors or | 3. | Replace damaged components. |

|

| housing. |

|

|

|

|

|

|

|

Inconsistent paint | 1. | Clogged Air Cap (1) or | 1. | Clean , adjust or replace Air Cap or Fluid |

flow, blobs and |

| damaged Fluid Nozzle (2). |

| Nozzle. |

splatters | 2. | Clogged Paint Filter (27). | 2. | Clean Paint Filter (27). |

| 3. | Damaged or dirty Paint | 3. | Clean, repair or replace Paint Needle (9). |

|

| Needle (9). |

|

|

| 4. | Contaminated paint. | 4. | Remove paint and filter it. |

Paint blows out | 1. | Air pressure set too high. | 1. | Adjust Air Regulator to no more than 45 PSI. |

too hard |

|

|

| Fine tune air pressure using Air Adjustment |

|

|

|

| Valve (31). |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

SKU 66222 | For technical questions, please call | Page 14 |