ASSEMBLY AND OPERATING INSTRUCTIONS (Continued)

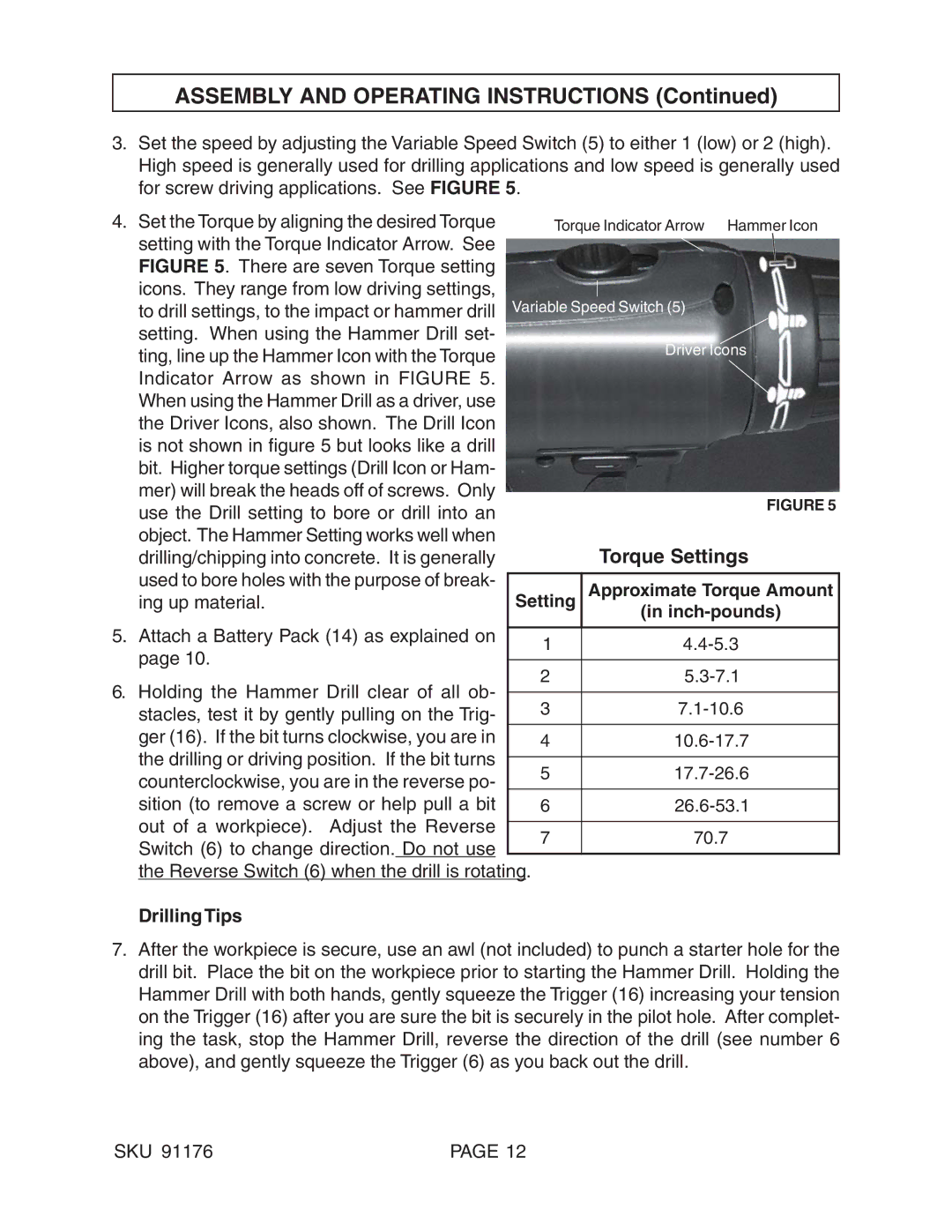

3.Set the speed by adjusting the Variable Speed Switch (5) to either 1 (low) or 2 (high). High speed is generally used for drilling applications and low speed is generally used for screw driving applications. See FIGURE 5.

4. | Set the Torque by aligning the desired Torque | Torque Indicator Arrow Hammer Icon | ||||

| setting with the Torque Indicator Arrow. See |

|

| |||

| FIGURE 5. There are seven Torque setting |

|

| |||

| icons. They range from low driving settings, | Variable Speed Switch (5) | ||||

| to drill settings, to the impact or hammer drill | |||||

| setting. When using the Hammer Drill set- |

| Driver Icons | |||

| ting, line up the Hammer Icon with the Torque |

| ||||

| Indicator Arrow as shown in FIGURE 5. |

|

| |||

| When using the Hammer Drill as a driver, use |

|

| |||

| the Driver Icons, also shown. The Drill Icon |

|

| |||

| is not shown in figure 5 but looks like a drill |

|

| |||

| bit. Higher torque settings (Drill Icon or Ham- |

|

| |||

| mer) will break the heads off of screws. Only |

| FIGURE 5 | |||

| use the Drill setting to bore or drill into an |

| ||||

|

|

| ||||

| object. The Hammer Setting works well when |

| Torque Settings | |||

| drilling/chipping into concrete. It is generally |

| ||||

| used to bore holes with the purpose of break- |

|

| |||

| Setting | Approximate Torque Amount | ||||

| ing up material. | |||||

|

|

|

|

| (in | |

5. | Attach a Battery Pack (14) as explained on |

|

| |||

1 | ||||||

| page 10. | |||||

|

|

| ||||

| 2 | |||||

6. | Holding the Hammer Drill clear of all ob- | |||||

|

| |||||

3 | ||||||

| stacles, test it by gently pulling on the Trig- | |||||

|

|

| ||||

| ger (16). If the bit turns clockwise, you are in | 4 | ||||

| the drilling or driving position. If the bit turns |

|

| |||

| 5 | |||||

| counterclockwise, you are in the reverse po- | |||||

|

|

| ||||

| sition (to remove a screw or help pull a bit | 6 | ||||

| out of a workpiece). Adjust the Reverse |

|

| |||

| 7 | 70.7 | ||||

| Switch (6) to change direction. Do not use | |||||

|

|

| ||||

|

|

| ||||

|

|

|

|

|

| |

| the Reverse Switch (6) when the drill is rotating. |

| ||||

DrillingTips

7.After the workpiece is secure, use an awl (not included) to punch a starter hole for the drill bit. Place the bit on the workpiece prior to starting the Hammer Drill. Holding the Hammer Drill with both hands, gently squeeze the Trigger (16) increasing your tension on the Trigger (16) after you are sure the bit is securely in the pilot hole. After complet- ing the task, stop the Hammer Drill, reverse the direction of the drill (see number 6 above), and gently squeeze the Trigger (6) as you back out the drill.

SKU 91176 | PAGE 12 |