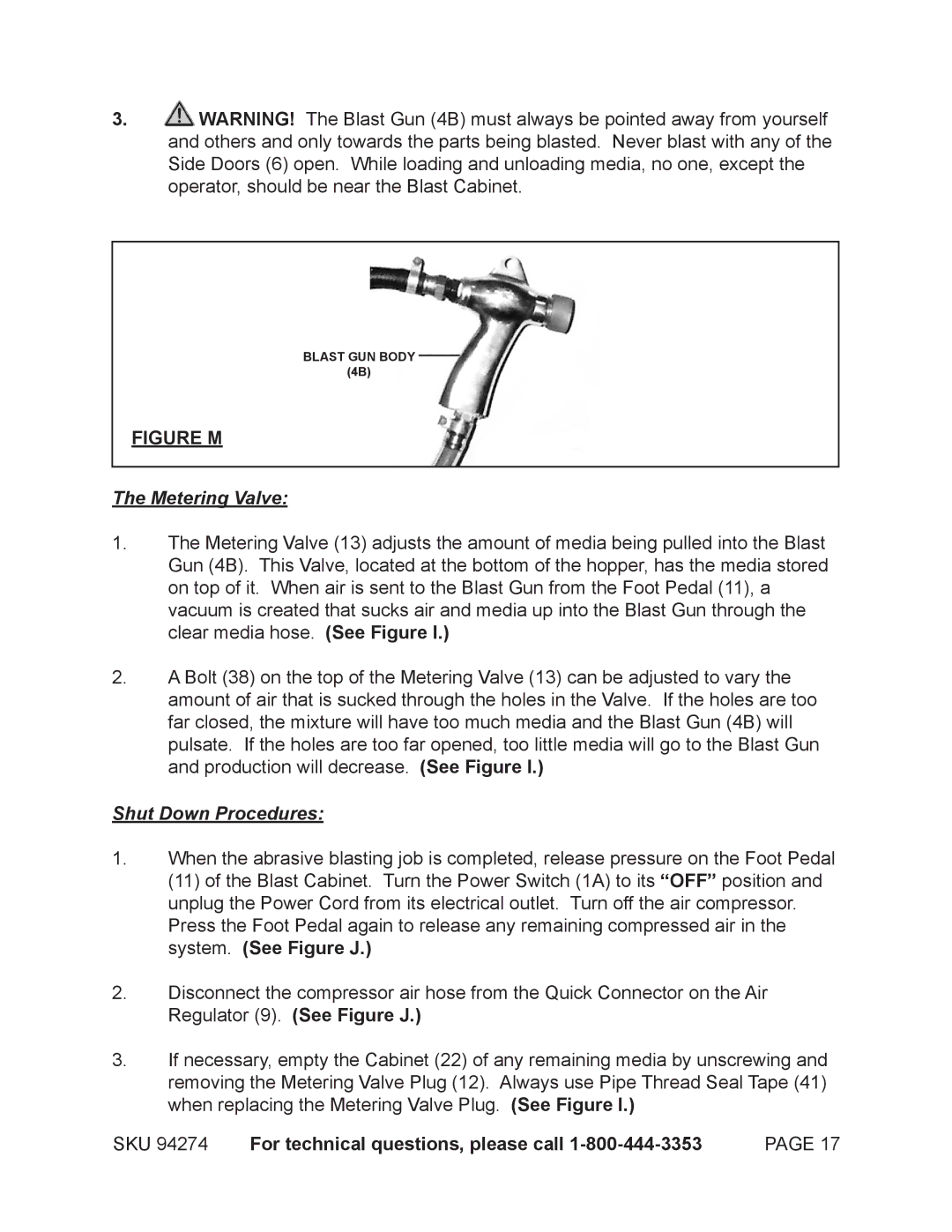

3.![]() WARNING! The Blast Gun (4B) must always be pointed away from yourself and others and only towards the parts being blasted. Never blast with any of the Side Doors (6) open. While loading and unloading media, no one, except the operator, should be near the Blast Cabinet.

WARNING! The Blast Gun (4B) must always be pointed away from yourself and others and only towards the parts being blasted. Never blast with any of the Side Doors (6) open. While loading and unloading media, no one, except the operator, should be near the Blast Cabinet.

BLAST GUN BODY

(4B)

FIGURE M

The Metering Valve:

1.The Metering Valve (13) adjusts the amount of media being pulled into the Blast Gun (4B). This Valve, located at the bottom of the hopper, has the media stored on top of it. When air is sent to the Blast Gun from the Foot Pedal (11), a vacuum is created that sucks air and media up into the Blast Gun through the clear media hose. (See Figure I.)

2.A Bolt (38) on the top of the Metering Valve (13) can be adjusted to vary the amount of air that is sucked through the holes in the Valve. If the holes are too far closed, the mixture will have too much media and the Blast Gun (4B) will pulsate. If the holes are too far opened, too little media will go to the Blast Gun and production will decrease. (See Figure I.)

Shut Down Procedures:

1.When the abrasive blasting job is completed, release pressure on the Foot Pedal (11) of the Blast Cabinet. Turn the Power Switch (1A) to its “OFF” position and unplug the Power Cord from its electrical outlet. Turn off the air compressor. Press the Foot Pedal again to release any remaining compressed air in the system. (See Figure J.)

2.Disconnect the compressor air hose from the Quick Connector on the Air Regulator (9). (See Figure J.)

3.If necessary, empty the Cabinet (22) of any remaining media by unscrewing and removing the Metering Valve Plug (12). Always use Pipe Thread Seal Tape (41) when replacing the Metering Valve Plug. (See Figure I.)

SKU 94274 | For technical questions, please call | PAGE 17 |