Flexible Motion Controller

FQM1 Series

Page

Omron

Omron Product References

Page

Table of Contents

Coordinator Module Functions 123

Inspection and Maintenance 259

Table of Contents

About this Manual

Name Cat. No Contents

Xii

Precautions

Intended Audience

General Precautions

Safety Precautions

Safety Precautions

Operating Environment Precautions

Application Precautions

Xvii

Xviii

Conformance to EC Directives

Conformance to EC Directives

Applicable Directives

Concepts

Countermeasure Examples

Current Characteristic Required element

Relay Output Noise Reduction Methods

Countermeasures

Name Model Cable length

Circuit Current Characteristic Required element

Charge the capacitor

Data Backup

Module Data Data backup

Temperature Initial After 5 years After 10 years

Backing Up DM Area Data in Flash Memory

Xxiv

Section

Section

Outline of FQM1 Flexible Motion Controller

Special I/O Servo Driver Pulse or Analog I/O Basic I/O

FQM1 Configuration

CJ1W-PA205R

FQM1-MMP21

FQM1-MMA21

Details

Modules

PLC

Outline of Internal Data Exchange and I/O

CX-Programmer

CX-Programmer

Systems

Expanded System Configuration

System Configuration

Serial Communications

Host Link System

Yes See note

FQM1

Serial Gateway

1N Connection between CJ1M and FQM1 Controllers

Connection between CJ1M and FQM1 Controller

No-protocol Custom Communications System via RS-422A Port

Basic Operating Procedure

Input wiring

Output wiring

Examples

Installation

Wiring Initial Hardware Settings

Writing the Programs

Transferring the Programs Testing Operation

Online Editing

Time Chart Monitoring

Save and Print the Programs

Data Tracing

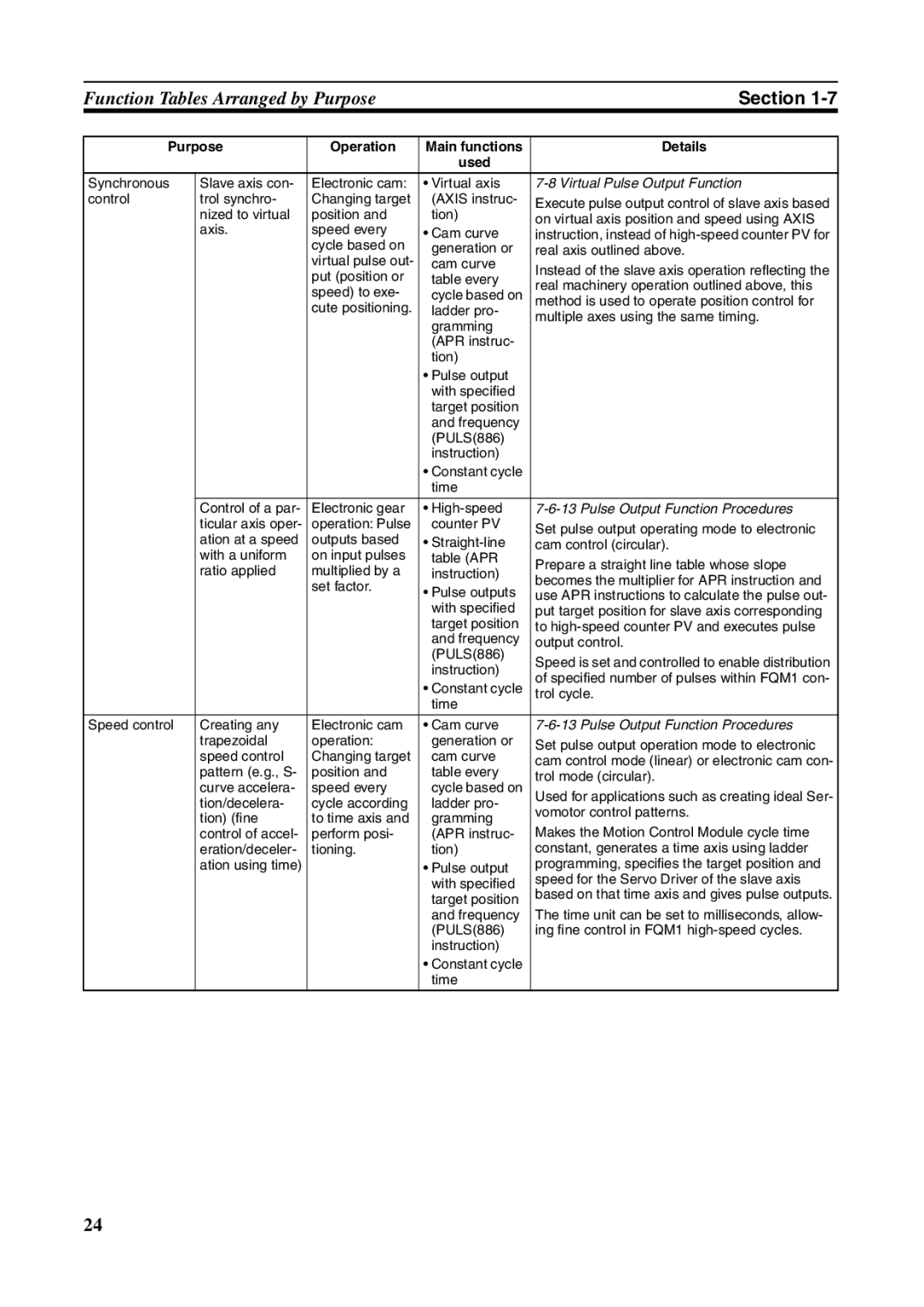

Purpose Operation Function used Details

Function Tables Arranged by Purpose

Function Tables Arranged by Purpose

Purpose Operation Main functions Details Used

Position and Speed Control

Absolute Encoders

Analog Outputs

Pulse Output Function Procedures

Measuring Input Pulses

High-speed Analog I/O Control

Analog Input Function Specifications

Pulse Outputs

Controlling Timing

Input Interrupt Mode

Time Measurement with the Pulse

Section

Specifications and Nomenclature

Name Type Model Specifications

General Specifications

General Specifications

Must be installed

VA max Inrush current At 100 to 120 V AC See note

Power Supply Unit Specifications

Nomenclature

Indicators

Indicator Color Name Status Meaning

Coordinator Module

Peripheral Port Baud Rate Detection/System Setup Switch

Function Specifications

Switch on Front Panel

Bits TR0 to TR15

Built-in General-purpose I/O

Specifications

Motion Control Modules

Motion Control Module

MMP21

FQM1-MMA21 Analog I/O

OUT7

MMA21

Performance Specifications

MMP21

Specifications

CW/CCW

Pulse I/O Specifications FQM1-MMP21 Pulse I/O

Pulse Inputs and Analog FQM1-MMA21 Analog I/O Specifications

FQM1-TER01 End Module

Dimensions

FQM1-CM001 Coordinator Module

Power Supply Units CJ1W-PA202

XW2B-80J7-1A Servo Relay Unit

Maximum Current Maximum Total Power Consumption

Module Current Consumption

Current Consumption for Each Module

Current Consumption for 24-V Systems

Example Calculation Current and Power Consumption

Combining Power Supply Units Motion Control Modules

Motion Control Modules

Areas Backed Up to Flash Memory

Memory Block Diagram

Motion Control Modules

Areas Backed Up by Super Capacitors

Section

Installation and Wiring

Accessibility for Operation and Maintenance

Installation

Installation and Wiring Precautions

Temperature Control

Improving Noise Resistance

Ing

Do not install the FQM1 in any of the following positions

FQM1 Orientation

Terminal Screws M4 1.2 N·m M3 0.5 N·m

Installation in a Control Panel

Wiring Ducts

FQM1 must be mounted inside a control panel on DIN Track

PLC FQM1

Assembled Appearance and Dimensions

Routing Wiring Ducts

Motion Control Module width 49 mm

Assembled Dimensions

Installation Dimensions

Coordinator Module width 49 mm

Installation Height

Connecting FQM1 Components

DIN Track Installation

Lock the pins on the backs of the Modules

PFP-100N/50N DIN Track

DIN Track and Accessories

DIN Track

PFP-100N2 DIN Track

Power Supply Capacity

Wiring

Wiring Power Supply Units

AC Power Source

Crimp Terminals

Grounding

Terminal Screws

FQM1

Crimp Terminals for Ground Wire

Connection Methods

2 RS-232C Port Wiring

WiringSection

Connector Pin Arrangement

Connecting to an IBM PC/AT or Compatible

Peripheral Bus Toolbus Serial Communications Mode

Applicable Connectors Coordinator Module Connector

IBM PC/AT or Compatible Connector 9-pin, Male

Direct Connection from RS-232C to RS-232C

RS-232C Port Specifications

Specification

Connection Example to Programmable Terminal PT

FQM1-CM001 Coordinator Module

Wiring Module Connectors

Connector Pin Arrangement

General-purpose I/O 40-pin Connector

Pin No Name

General-purpose I/O 26-pin Connector

FQM1-MMP21 Pulse I/O 40-pin Connector

FQM1-MM@21 Motion Control Modules

Pin Name

FQM1-MMA21 Analog I/O 40-pin Connector

Pulse Outputs

External Connection Diagrams

Input between 4 and 20 mA

Are outlined in the following tables

Example

Wiring Examples

Connecting Pulse Inputs FQM1-MMP21 MMA21

Power supply Encoder

FQM1-MMP21

Connecting Pulse Outputs FQM1-MMP21

Connectors

Wiring Methods

Connecting Analog Outputs FQM1 MMA21

Connecting Analog Inputs FQM1-MMA21

Recommended Wire Size

Wiring Servo Relay Units

Applicable Connector-Terminal Block Conversion Units

Nomenclature and Functions

RS-422 Connector

Pin No Signal

Lower Terminal Block Pin Arrangement

Upper Terminal Block Pin Arrangement

Switch Setting details

Signal Switches

Following screwdriver can be used when removing wires

External Dimensions

Wiring Screw-less Clamp Terminal Blocks

Wiring Method

Phoenix Contact Inc

Recommended Screwdriver

Model Manufacturer

Sysmac PLC

Wiring when Using Servo Relay Units

Lower Terminal Block Arrangement

Example Servo Relay Unit Wiring

Upper Terminal Block Arrangement

Specifications Model

List of FQM1 Connecting Cables

Connecting Cable Models

RS-422A Connecting Cables with 9-pin D-sub Connector

Reducing Electrical Noise

Wiring Precautions

Signal Wiring

OUT

External Wiring

Surge suppressor specifications Diode specifications

Inductive Loads

COM +

Connecting I/O Devices

Input Devices

VON ≤ VCC VR

Precautions when Connecting a Two-wire DC Sensor

Residual Voltage

Output Wiring Precautions

Output Short-circuit Protection

Transistor Output

Method

Add a control resistor as shown in the following diagram

Output Surge Current

Reduce the surge current

Operation

Memory

Outline

User Program

Coordinator Module Operation

System Setup Flash Memory

Refreshing

Servicing Contents

3 I/O Refreshing and Peripheral Servicing

Startup Initialization

User Program Area

Description of Each Area

Motion Control Module Operation

Memory System Setup Read/Write DM Area D00000 to D32767

System Setup Using CX-Programmer

Tab Settings

Ules. Refer to 5-4 Synchronous Data Refresh for details

Sync Mode Operation

Same time

Scan or at the specified sync cycle time. See note

Program

Operating Modes

Following tables list status and operations for each mode

Mode Cyclic task status Interrupt task status

Operating Modes

Mode Changes Cleared areas Retained areas

Power OFF Operation

Operating Mode Changes and I/O Memory

Power OFF Operation

Power Holding Time

Power OFF Timing Chart

Fixed Power OFF Detection Time

User-set Power OFF Detection Time

Description of Operation

Instruction Execution for Power Interruptions

Module Functions and Data Exchange

Sync and ASync Modes

Sync Mode

ASync Mode

Synchronous Operation between Modules

Method Outline Description

Data Exchange between Modules

Applications

Cyclic Refresh

Word Bits Details Address

Cyclic Refresh Area Details

Coordinator Module Cyclic Refresh Area

Motion Control Module Cyclic Refresh Areas

Bit

Cyclic Refresh Area Allocations

CM Coordinator Module MM Motion Control Module

Bits Details

Synchronous Data

Synchronous Data Refresh

Sync Cycle Time

Transfer time

Input or analog output value in the System Setup

Synchronous Data Link Bit Area

Ladder execution results data

Synchronization between Modules

Settings

System Setup Coordinator Module

Trol Modules

Interruption of the Sync

System Setup Motion Control Modules

DM Data Transfer

Prohibit System

Area

Settings Details

Make Auxiliary Area Settings

Executing DM Data Transfer

Turn on Request Bit Programming Example

Cycle Time Settings

Constant Cycle Time Function

Constant Cycle Time Function Enabled for Coordinator Module

Constant Cycle Time Function in Sync Mode

System Setup

Constant Cycle Time Exceeded Error Clear Bit

Auxiliary Area Words

Watch Cycle Time Function

Cycle Time Monitoring Function

Cycle Time Too Long Flag

Auxiliary Area Bits

Clearing Constant Cycle Time Exceeded Errors

Constant Cycle Time Exceeded Error Clear Function

Normal Operation

Program Protection

Operation Settings at Startup and Maintenance Functions

Specifying the Startup Mode

Tab Name Details Settings Default

Flash Memory

Automatic Backup to Flash Memory

Password Protection

Name Address Meaning

Diagnostic Functions

Error Log

Auxiliary Area Flags

Operation of FAL006

Failure Alarm Functions

Operation of FALS007

Coordinator Module Functions

Peripheral 232C 422A

Serial Communications

FQM1 supports the following serial communications functions

Protocol Connections Description

Serial Communications

FQM1. Select the method that best suits your application

Procedure

Host Link Communications

Type Header Name Function Code

Host Link Commands

Type Command Name Function Code

Fins Commands

CR+LF

Forced SET/RESET

Forced SET/RESET Cancel

No-protocol Communications RS-232C Port

CR+LF

End code setting Yes

Message Frame Formats

On the TXD236 and RXD235 instructions

NT Link 1N Mode

System Setup RS-232C Settings Host Link Port Settings

Setting Default Enabled

CIO 0080 to CIO 0089 CJ1M master to FQM1 slave

Serial PLC Links

Overview

Ule are shared with the CJ1M master as shown below

Source Words and Number of Link Words

CJ1M Master Settings

FQM1 Slave Settings

Function

Settings

Smartstep

Smart Active Parts Communications Settings

Settings Default Enabled

No-protocol Communications RS-422A Port

RS-422A Settings

Motion Control Module Functions

138

Main function Sub-functions Applicable Modules

Overview

OverviewSection

FQM1 Modules have the following functions

Executing Interrupt Programs

Interrupt Functions

Overview

Interrupt Priority

Enabling All Interrupts

DI802 instruction will disable all interrupts

Disabling and Enabling All Interrupts

Disabling All Interrupts

Overview of the Input Interrupt Function

Input Interrupt Specifications

Input Interrupts

Applicable Models

Input Allocated input bit Interrupt task number

Using Input Interrupts

Counter Mode

Input Interrupt Mode Procedure

Counter Mode Procedure

Application Example

Equipped with one interval timer each

Interval Timer Interrupts

Interval Timer Interrupt Modes

Using Interval Timer Interrupts

@STIM

Stim Interval Timer

Model Functions

Specifications

Pulse Inputs

Based on the counter PV

Pulse Inputs

Pulse Input Specifications

151

Pulse Inputs

Latch Input Specifications

Internal Circuit Configurations

Applicable Instructions

High-speed Counter Function Description

Pulse Input Function Description

Linear Counter

Reset Methods

Counter Operation Numeric Ranges

Circular Counter

Target-value Comparison Method

Phase-Z Signal Reset Input and Software Reset

Software Reset

Checking for High-speed Counter Interrupts

Range Comparison Method

Tab Function Details

Monitoring High-speed Counter Movement Mode

Word Bits Function Details

System Setup Function Details

Word Bit Function Details

High-speed Counter Procedure

Pulse Input Function Procedures

Target-value comparison interrupt

Mode 1 Procedure

Pulse Input Function Example Application

Mode 2 Procedure

Procedure

163

164

165

Example Latching High-speed Counter PV

Pulse Outputs

168

One-shot Pulse Outputs

All Pulse Outputs Except for One-shot Pulse Outputs

Instructions Ineffective during Pulse Output

Sible is also listed in the following table

Pulse Output Function Details

Mode Description

172

SPED88

Pulse Output Operations

PULS88

Dividing ratio

Precautions when Using Pulse Outputs

Target frequency

Set by user

Target frequency Hz Actual output frequency

One-shot Pulse Output Function

Formula

Word Bits Function Contents

One-shot Pulse Output Specifications

Tab Function Setting

Time Measurement with the Pulse Counter

Target-value Comparison Interrupts from Pulse Output PVs

Pulse Counter Timer Specifications

Linear Mode Operation

END ACC

Range Comparison Bit Pattern Outputs from Pulse Output PVs

Circular Mode Operation

Ms Cycle

12 PLS2887 Pulse Output Direction Priority Mode

Setting

Speed-change Cycle

Execute PLS2887 with A628.14 OFF

Pulse Output Function Procedures

Setting the Pulse Output Direction Priority Mode

Pulse Output Direction Priority Mode

Pulse output port

Pulse Outputs with Acceleration/Deceleration

Port Pulse output port

Electronic Cam Control Functions

187

One-shot Pulse Output STIM980

Pulse Counter Timer Function STIM980

@SPED

Pulse Output Function Examples

Accelerating the Frequency at a Fixed Rate

Changing the Frequency in Steps

Speed

Number of pulses is 0 or more

192

@PLS2

Using PLS2887 for Trapezoidal Acceleration/Deceleration

One-shot Pulse Output Function Example

Pulse Counter Time Measurement Timer Example

Supports continuous mode only

Pulse Output Starting Conditions

CCW

Use this function for positioning

SPED8 PULS8 PULS88

PULS886 Absolute Pulse Output in Progress

Target position Present position

Case

Absolute linear

Cases 7, 11, 12

Cases 6, 8, 9,

199

P is in ASCII. It is 50 hex in hexadecimal

Serial Data Specification

Data Format of Absolute Encoder Output

Data Format

Counting Operation Counter Operation Details

Counter Operation

Absolute Linear Counter Absolute Circular Counter

Absolute Number of Rotations PV Counter 1 A604 and A605

Absolute Present Value

7FFF

Absolute Present Value Preset

Absolute Offset Preset

Related Areas

Tab Function Details Time when Setting

Word Bits Function Details Controlled

Auxiliary Area

206

Acquiring Method

Overview of Absolute Encoder Output Data Acquire

Absolute Encoder

Output Data

208

Program Description

Sample Programs Connecting an Omron W-series Servo Driver

210

211

Axis

Virtual Pulse Output Function

Operands

Mode Specifier Sets the output mode

First Word of Setting Table

Axis Instruction For Virtual Pulse Outputs

Description

Motion Control Module for Analog I/O

Positioning or Speed Control Using a Virtual Axis

Analog Input Functions

FQM1-MMA21

Analog Input Function Specifications

Tab Function Settings Time when setting Becomes effective

Related Areas and Settings

Word Bits Function Settings Controlled

220

221

With END Refreshing With Immediate

Signal Range −10 to 10 Signal Range 0 to 10

6 A/D Conversion Value

Overview CTBL882 Instruction Operation

Signal Range 1 to 5 V and 4 to 20 mA

Signal Range 0 to 5

High-speed Analog Sampling FQM1-MMA21 Only

Comparison Table

At several measurement points

@CTBL

Analog Outputs

Analog Outputs

Analog Output Function Specifications

Condition Analog output

Overall accuracy is the ratio of accuracy to the full scale

CPU standby status

To 5

Specified Output Values and Analog Output Signals

END Refreshing With Immediate Refreshing

To 10

Procedure

Outputting a Sloped Analog Output

Outputting the Analog Output Value Stored Auxiliary Area

Outputting a Stepped Analog Output

231

232

Connecting the CX-Programmer

CS1W-CIF31

Make System Setup settings, and monitor or debug operation

Name Model Specifications

Cables shown in the following table

Connecting a Personal Computer Running Support Software

Connecting the CX-Programmer

System Configuration

CS1W-CIF31

Cable Connection Diagram

Connection Methods Using a USB-Serial Conversion Cable

Cable Port Communic Connecting Ations Connector Model

CX-Programmer Connecting Cables

Serial Features Communications Mode

Connecting an RS-232C Cable to the RS-232C Port

When connecting the CX-Programmer to the FQM1

Connecting an RS-232C Cable to the Peripheral Port

240

Error Processing

Instruction FAL numbers Error codes

Error Log

Errors Generated by FAL006/FALS007

Error Log Structure

Indicator Status and Error Conditions

Error Processing

Error Categories

Error Information

Prphl OFF COMM1 COMM2

Error Codes

Classification Error code Error name

ERR OFF

Error Processing Flowchart

CPU Standby

Error Tables

CPU Errors

Fatal Errors

247

Fatal Errors

Lit Flashing

Non-fatal Errors

Non-fatal Errors

C2FF

Other Errors

Power Supply Check

Program Error Check

Memory Error Check

System Setup Error Check

Cycle Time Overrun Error Check

11 I/O Setting Error Check

12 I/O Check

Environmental Conditions Check

Troubleshooting Problems in Modules

Coordinator Module Errors

Error condition Probable cause Remedy

Input Errors

Motion Control Module Errors

Output Errors

Inspection and Maintenance

Inspection Criteria Action

Inspections

Inspection Points

Inspection Points for Periodic Inspections

Tools Required

Module Replacement Precautions

Tools Required for Inspections

Required Tools

262

Type of task Description

Programming Programs and Tasks

Tasks

Type of subroutine Description Calling instruction

Using Normal Subroutines

Subroutines

What Are Subroutines?

Overview

Using Subroutines That Pass Parameters

Execution without Subroutine Input Condition Flags

Execution with Subroutine Input Condition Flags

JSB

JSB982 Operation

Address Corresponding subroutines Word Bits

RET

Appendix a

Mcro

Main Program

Instruction Conditions

Power Flow

Basic Information on Programming

Basic Information on Instructions

Operands

Instruction Description Setting Canceling Condition

Operand types Description Symbol

Flags

Word Addresses

Instruction Location and Input Conditions

Addressing I/O Memory Areas

Bit Addresses

Operand Description Notation Application

Specifying Operands

BCD

Operand Description Notation Application Examples

#FFFFFFFF

Data Operand Data form Symbol Range Application example

LD ,IR0

BCD

NUL NUL

Abcde

NUL

Abcd

Decimal Digit

Data Formats

Data type

Two’s Complements

Complements

7FFF

Decimal Hexadecimal Binary

Ffff

Fffe

Non-differentiated Instructions

Variation Symbol Description

Instruction Variations

Input Conditions

280

Condition Flags

Programming Precautions

Using Condition Flags

Using Execution Results in NC and no Inputs

CMP

Difu

Using Execution Results from Differentiated Instructions

Error Flag

Main Conditions Turning on Condition Flags

Negative Flag

Equals Flag

Carry Flag

Less Than and Greater Than Flags

Program section Instructions Instruction condition Status

Special Program Sections

Instruction Combinations

Subroutines

Following instructions cannot be placed in a subroutine

Instructions Not Allowed in Subroutines

Instructions Not Allowed in Step Ladder Program Sections

Instructions Not Allowed in Block Program Sections

YES

FQM1 Operation Flowchart

Computing the Cycle Time

Calculating the Cycle Time of the Coordinator Module

Overview of Cycle Time Calculations

Coordinator Module

Motion Control Modules

Cyclic Refreshing

Peripheral Service

Calculating the Cycle Time of a Motion Control Module

Sync Bus Refreshing

Model Refresh time

Module I/O Refresh Times

Cyclic Refresh Time in the Coordinator Module

Cyclic Refresh Time in Motion Control Modules

Calculation Example for FQM1-MMP21

Example of Calculating the Cycle Time

Online Editing Cycle Time Extension

Conditions

Coordinator Module I/O Response Time

Response Time

Response Time

Minimum I/O Response Time General-purpose I/O 0 to

Motion Control Module I/O Response Time

Input Interrupt Tasks

Interrupt Response Times

Motion Control Module Interrupt Response Times

Response Time for Pulse and Analog I/O

Scheduled Interrupt Task

Motion Control Module Interrupt Processing Times

Maximum Response Time

Processing Time

Interrupt Response Time Calculation Example

Minimum Response Time

298

Parameter Area

Memory Overview of I/O Memory

Introduction

CIO

Memory Structure

Coordinator Module

Motion Control Modules

Bit Area CIO 0000 and CIO

CIO Area

END Refresh

Refresh

Synchronous Data Link Bit Area CIO 0200 to

Serial PLC Link Bit Area CIO 0080 to CIO

Temporary Relay Area TR

Refreshing Using the IORF097 Instruction

Work Area W000 to W255 W000.00 to W255.15, 4,096 Bits

Auxiliary Area A000 to A649 A000.00 to A649.15

Timer Area

Appendix B

Counter Area

BCD-mode Addressing *D

Data Memory DM Area

Condition Flags

Binary-mode Addressing @D

Summary of the Condition Flags

Using the Condition Flags

Name CX-Programmer Function Symbol

Clock Pulses

Using the Clock Pulses

Name Label CX-Programmer Operation Symbol

Parameter Area

System Setup

Allow Writing to User Memory

System Setup in the Coordinator Module

Prohibit System Interrupt of the Sync Mode

Appendix C

Startup Mode Setting CX-Programmer Startup Tab

Cycle Time Settings CX-Programmer Timer/Peripheral Service

Peripheral Port Settings for Host Link

Peripheral Port Settings CX-Programmer Peripheral Port Tab

Host Link Unit Number

Peripheral Port Settings for NT Link

Peripheral Port Settings for Peripheral Bus ToolBus

Standard/Customer Setting

Format

RS-232C Port Settings for Host Link

RS-232C Port Settings for Peripheral Bus ToolBus

RS-232C Port Settings for NT Link

Data Format

RS-232 Port Settings for No-protocol Communications RS-232C

Send Delay

PLC Link Unit No. PC Link Unit Number

RS-232C Port Settings for PLC Link PC Link Slave

Start Code and End Code

Number of Received Bytes

Send Delay Time

Peripheral Service Time

Fixed Service Time Enable Setting Set Time to All Events

CX-Programmer Cycle Time Tab

System Setup in Motion Control Modules

Settings Used by All Motion Control Modules

CX-Programmer Module Settings Tab

CX-Programmer Pulse Input Tab

FQM1-MMP21 Motion Control Modules with Pulse I/O

Function Details

CX-Programmer Pulse Output Tab

FQM1-MMA21 Motion Control Modules with Analog I/O

Address Bits Function Remarks When setting

RS-232C Port Settings Host Link Port

Details on System Setup Settings

Startup Mode

Peripheral Port Settings

Watch Cycle Time

Messages Sent and Received with No-protocol Mode

Constant Cycle Time

Over

Fixed Peripheral Servicing Time

328

FQM1-MMP21 Motion Control Modules with Pulse I/O

Auxiliary Area Allocations by Function

Allocations That Are the Same for All Modules

330

331

332

333

334

335

FQM1-MMA21 Motion Control Modules with Analog I/O

337

338

339

340

341

342

Appendix C

Allocations Related to Built-in Inputs

System Flags

Program Error Flags

Other Error Flags and Bits

Error Log and Error Code

Module Errors

FAL/FALS Errors

Memory Errors

Errors

Peripheral Port

Communications

Other

RS-422A Port

Allocations Directly Related to Instructions

RS-232C Port

Motion Control Module Built-in I/O Allocations

Coordinator Module Built-in I/O Allocations

Appendix D

Appendix D

351

352

353

354

355

356

357

358

Detailed Explanations on the Auxiliary Area

Error Codes and Error Flags

Error Log Area A100 to A199

Classification Error code Meaning Error flags

FQM1 Memory Addresses

Memory Configuration

Memory Map

Sequence Output Instructions

FQM1 Instruction Execution Times and Number of Steps

Sequence Input Instructions

Comparison Instructions

Timer and Counter Instructions

Sequence Control Instructions

Data Movement Instructions

Increment/Decrement Instructions

Data Shift Instructions

Symbol Math Instructions

Logic Instructions

Conversion Instructions

Floating-point Math Instructions

Special Math Instructions

Subroutine Instructions

Table Data Processing Instructions

Data Control Instructions

High-speed Counter and Pulse Output Instructions

Interrupt Control Instructions

Refresh Instruction

Step Instructions

Other Instructions

Serial Communications Instructions

Debugging Instructions

Failure Diagnosis Instructions

Iend

If not

Else

374

Index

Index

377

378

379

Page

381

382

383

384

385

386

Original production

Revision code Date Revised content

Revision History

388

Regional Headquarters

Omron Corporation

Terms and Conditions of Sale

Omron Electronics LLC