FQM1 Series

OPERATION MANUAL

Flexible Motion Controller

FQM1-CM001 FQM1-MMP21 FQM1-MMA21

FQM1-CM001 FQM1-MMP21 FQM1-MMA21

Flexible Motion Controller Operation Manual

FQM1 Series

Produced November

Page

Notice

OMRON Product References

Visual Aids

OMRON,

Page

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION

TABLE OF CONTENTS

Inspection and Maintenance

SECTION

Appendices

TABLE OF CONTENTS

About this Manual

Page

PRECAUTIONS

xiii

2 General Precautions

3 Safety Precautions

1 Intended Audience

Intended Audience

3-1Operating Environment Precautions

Safety Precautions

3-2Application Precautions

Safety Precautions

•Changing the operating mode of the FQM1

Safety Precautions

xvii

xviii

Safety Precautions

•Do not apply voltages or connect loads to the built-inoutputs in excess of the maximum switching capacity. Excess voltage or loads may result in burning

Conformance to EC Directives

EMC Directive Conformance Conditions

Conformance to EC Directives

EMC Directives

4-5Relay Output Noise Reduction Methods

Conformance to EC Directives

Countermeasures

Countermeasure Examples

Characteristic

Conformance to EC Directives

Motion Controller

Circuit

xxii

5 Data Backup

Data Backup

Data Backup

Backing Up DM Area Data in Flash Memory

xxiii

A404.14

Data Backup

xxiv

SECTION Features and System Configuration

1-1Outline of FQM1 Flexible Motion Controller

Flexible Configurations of Up To 8 Axes

Outline of FQM1 Flexible Motion Controller

Section

Outline of FQM1 Flexible Motion Controller

Section

Built-in RS-232CPort in Coordinator Module

Built-in RS-422APort in Coordinator Module

1-2FQM1 Configuration

FQM1 Configuration

Section

Pulse Input Frequency Measurement Function

FQM1 Configuration

CJ1W-PA202/PA205RPower Supply Units

Section

FQM1-CM001Coordinator Module

Section

Modules

Modules

Outline of Internal Data Exchange and I/O

Modules

Section

1-4 CX-Programmer

CX-Programmer

Section

CX-Programmer

1-5Expanded System Configuration

Expanded System Configuration

System Configuration

Section

Expanded System Configuration

Section

Host Link System

NT Link System 1:N Mode, Standard

NT Link 1:N Mode RS-232C PT NT Link 1:N Mode

Expanded System Configuration

Section

Expanded System Configuration

System Configuration Example

Section

Serial Gateway

Section

1-6Basic Operating Procedure

Basic Operating Procedure

Section

Basic Operating Procedure

3.Initial Hardware Settings

Basic Operating Procedure

1. Installation

2.Wiring 3.Initial Hardware Settings

1-6-1Examples

Basic Operating Procedure

5.System Setup Settings

Section

6.Writing the Programs

Basic Operating Procedure

7.Transferring the Programs 8.Testing Operation

8-aI/O Wiring Checks 8-bTrial Operation

Check Output Wiring

Basic Operating Procedure

Time Chart Monitoring

Section

9.Save and Print the Programs

Function Tables Arranged by Purpose

5-4-4Settings

1-7-1

Sync Cycles and Synchronized data

Function Tables Arranged by Purpose

Section

5-1Synchronous Operation between Modules

5-1Synchronous Operation between Modules

1-7-2

Function Tables Arranged by PurposeSection

7-6-6Pulse Output Function Details

7-6-12PLS2887 Pulse Output Direction Prior

Function Tables Arranged by Purpose

Section

Absolute Encoders

7-6-6Pulse Output Function Details

Function Tables Arranged by Purpose

Section

7-10Analog Outputs

7-8Virtual Pulse Output Function

7-6-13Pulse Output Function Procedures

7-6-13Pulse Output Function Procedures

Function Tables Arranged by Purpose

Section

1-7-3

Function Tables Arranged by Purpose

Section

7-9Analog Input Functions

7-9-3Analog Input Function Specifications

1-7-4

Function Tables Arranged by Purpose

Section

Function Tables Arranged by Purpose

Section

7-9Analog Input Functions

7-6Pulse Outputs

7-4Interval Timer Interrupts

7-4-3Interval Timer Interrupt Modes

7-4Interval Timer Interrupts

7-4-3Interval Timer Interrupt Modes

Function Tables Arranged by Purpose

Section

7-5Pulse Inputs

7-6-8Time Measurement with the Pulse

Function Tables Arranged by Purpose

Section

SECTION Specifications and Nomenclature

General Specifications

List of Models

General Specifications

List of ModelsSection

Section

General Specifications

Power Supply Unit Specifications

2-3Coordinator Module

Indicators

Coordinator Module

Section

Function Specifications

Switch on Front Panel

Coordinator Module

Section

CIO Area

Coordinator Module

Section

Motion Control Modules

I/O Specifications

Motion Control Modules

Section

Indicators

Motion Control Modules

Section

Nomenclature

Section

Performance Specifications

Motion Control Modules

I/O Specifications

General-purposeI/O Specifications

Motion Control Modules

Section

Pulse I/O Specifications

Motion Control Modules

Section

FQM1-MMP21Pulse I/O

I/O Specifications

Motion Control Modules

Section

Pulse Inputs and Analog

2-5Dimensions

Dimensions

Section

FQM1-CM001Coordinator Module

Dimensions

Power Supply Units

POWER L1

POWER L1

2-6Module Current Consumption

Maximum Current and Maximum Total Power

Module Current Consumption

Section

Example Calculation of Current and Power

Combining Power Supply Units and Motion Control

Module Current Consumption

Section

2-7Memory Block Diagram

Memory Block Diagram

Section

Areas Backed Up by Super Capacitors

Memory Block Diagram

Section

SECTION Installation and Wiring

3-1Installation

Installation

Installation in Cabinets or Control Panels

Temperature Control

Installation

Power lines 200 mm min FQM1 200 mm min

Section

Improving Noise Resistance

FQM1 Orientation

Installation

Section

3-1-2Installation in a Control Panel

Installation

Wiring Ducts

Wiring Duct Example

3-1-3Assembled Appearance and Dimensions

Installation

Routing Wiring Ducts

Section

Installation

Assembled Dimensions

Installation Dimensions

Power Supply Unit width: “a” mm

3-1-4Connecting FQM1 Components

Installation

Installation Height

Section

3-1-5DIN Track Installation

Installation

Release DIN Track mounting pins

Section

Section

Installation

2 3. Lock the pins on the backs of the Modules

Installation

DIN Track and Accessories

Section

•DIN Track

3-2Wiring

Wiring

AC Power Source

Power Supply Capacity

Wiring

Section

Grounding

Terminal Screws and

Wiring

Section

FQM1

Control panel

Wiring

Crimp Terminals for Ground Wire

Section

Terminal Screws and

WiringSection

Connector Pin Arrangement

Connection Methods

1:1 Connections with

Wiring

Applicable Connectors

Coordinator Module Connector

IBM PC/AT or Compatible Connector 9-pin,Male

Wiring

RS-232CPort Specifications

Section

Connection Example to Programmable Terminal PT

3-3Wiring Module Connectors

Wiring Module Connectors

General-purposeI/O 40-pinConnector

Section

Wiring Module Connectors

General-purposeI/O 26-pinConnector

FQM1-MMP21Pulse I/O 40-pinConnector

Section

Section

Wiring Module Connectors

FQM1-MMA21Analog I/O 40-pinConnector

Wiring Module Connectors

3-3-2

Section

FQM1-MM@21Motion Control Modules

3-3-3Wiring Examples

Wiring Module Connectors

Connecting Pulse Inputs FQM1-MMP21 MMA21

Section

Wiring Module Connectors

Power supply Encoder

Section

FQM1 Shielded twisted-paircable

Wiring Module Connectors

Connecting Pulse Outputs FQM1-MMP21

Section

Example

Wiring Module Connectors

Connecting Analog Outputs FQM1 MMA21

Connecting Analog Inputs FQM1-MMA21

Connectors

3-4Wiring Servo Relay Units

Wiring Servo Relay Units

Recommended Wire Size

Section

Nomenclature and Functions

Wiring Servo Relay Units

Section

Wiring Servo Relay Units

Section

Upper Terminal Block Pin Arrangement

Lower Terminal Block Pin Arrangement

Section

Wiring Servo Relay Units

6. Signal Switches

Wiring Servo Relay Units

External Dimensions

Wiring Screw-less Clamp Terminal Blocks

Wiring Method

Wiring Servo Relay Units

Section

Recommended Screwdriver

Model

Section

Wiring Servo Relay Units

Wiring when Using Servo Relay Units

Wiring Servo Relay Units

Example Servo Relay Unit Wiring

Section

Upper Terminal Block Arrangement

3-5List of FQM1 Connecting Cables

List of FQM1 Connecting Cables

Connecting Cable Models

Section

Section

List of FQM1 Connecting Cables

6.Servomotor Connecting Cables

3-6Wiring Precautions

Wiring Precautions

I/O Signal Wiring

3-6-1Reducing Electrical Noise

Wiring Precautions

External Wiring

Surge suppressor specifications

Diode specifications

3-6-2Connecting I/O Devices

Wiring Precautions

Section

Input Devices

Wiring Precautions

Precautions when Connecting a Two-wireDC Sensor

Section

1,2,3

Wiring Precautions

Output Wiring Precautions

Section

Output Short-circuitProtection

Wiring Precautions

Section

FQM1

FQM1

SECTION Operation

4-1Coordinator Module

Coordinator Module

Section

User Program

System Setup Flash Memory

4-1-2Coordinator Module Operation

Coordinator Module

Section

4-1-3I/O Refreshing and Peripheral Servicing

4-1-4Startup Initialization

Coordinator Module

Section

4-2Motion Control Modules

4-2-1Outline

4-2-2Description of Each Area

Motion Control Modules

I/O Memory System Setup

System Setup Using CX-Programmer

Motion Control Modules

Section

Sync Mode Operation

Motion Control Modules

Section

Initialization at At power ON Common Processing

Motion Control Modules

Section

Program Execution

4-3Operating Modes

4-3-2

Status and Operations in Each Operating Mode

Operating Modes

4-4Power OFF Operation

4-4-1Power OFF Operation

Power OFF OperationSection

4-3-3Operating Mode Changes and I/O Memory

Power OFF Operation

Power OFF Timing Chart

Fixed Power OFF Detection Time

User-setPower OFF Detection Time

Description of Operation

Power OFF Operation

Section

SECTION Module Functions and Data Exchange

Synchronous Operation between Modules

Synchronous Operation between ModulesSection

Sync and ASync Modes

Sync Mode

Section

5-2Data Exchange between Modules

Data Exchange between Modules

5-3Cyclic Refresh

5-3-1Outline

5-3-2Applications

Cyclic Refresh

5-3-3Cyclic Refresh Area Details

Cyclic Refresh

Section

Coordinator Module Cyclic Refresh Area

Cyclic Refresh Area Allocations

5-3-4

Cyclic Refresh

Section

Synchronous Data Refresh

5-4-1

Outline

5-4-2

Synchronous Data Link Bit Area

5-4-3

Synchronous Data Refresh

Section

System Setup Coordinator Module

Synchronous Data Refresh

Section

Synchronization between Modules

5-5DM Data Transfer

System Setup Motion Control Modules

DM Data Transfer

Section

Settings Details

Step 1: Make Auxiliary Area Settings

5-5-3Executing DM Data Transfer

5-5-2

5-6Cycle Time Settings

Cycle Time Settings

5-6-1Constant Cycle Time Function

Section

Cycle Time Settings

System Setup

Constant Cycle Time Exceeded Error Clear Bit

Section

Cycle Time Settings

System Setup

Section

Cycle Time Too Long Flag

Cycle Time Settings

Constant Cycle Time Exceeded Error Clear Function

Section

Normal Operation

Read Protection Using Passwords

System Setup

5-7-1Specifying the Startup Mode

5-7-2Program Protection

Automatic Backup to Flash Memory

Password Protection

5-7-3Flash Memory

Section

5-8Diagnostic Functions

Diagnostic Functions

Refer to SECTION 9 Error Processing for details

Section

5-8-2Failure Alarm Functions

Diagnostic Functions

Section

Operation of FAL006

Diagnostic Functions

Section

Operation of FALS007

FALS

SECTION Coordinator Module Functions

Serial Communications

Serial CommunicationsSection

Serial Communications

Section

Procedure

Host Link Communications

6-1-1

Serial CommunicationsSection

Host Link Commands

Section

Serial Communications

Link Units System Manual W143 for details

Section

FINS Commands

Serial Communications

Section

6-1-2 No-protocolCommunications RS-232CPort

Serial Communications

Procedure

End code setting

Serial Communications

Section

System Setup

RS-232CSettings Host Link Port Settings

System Setup

Serial Communications

System Configuration

6-1-4Serial PLC Links

Serial CommunicationsSection

Overview

Procedure

CJ1M Master Settings

FQM1 Slave Settings

Serial Communications

Settings

CJ1M Master PLC Setup

FQM1 Slave System Setup

System Configuration

System Setup

Smart Active Parts Communications Settings

Serial Communications

Section

RS-422ASettings

6-1-6 No-protocolCommunications RS-422APort

Serial Communications

Section

SECTION Motion Control Module Functions

7-6-10

Overview

OverviewSection

7-2Interrupt Functions

Interval Timer Interrupts

Interrupt Functions

Section

7-2-3Disabling and Enabling All Interrupts

Interrupt Functions

Section

Disabling All Interrupts

Input Interrupts

Input Interrupts

Section

Clearing Recorded Interrupts

7-3-5Using Input Interrupts

Input Interrupt Mode Procedure

Input Interrupts

Section

Counter Mode Procedure

Input Interrupts

Section

1,2,3

Section

7-3-6Application Example

Input Interrupts

7-4Interval Timer Interrupts

Interval Timer Interrupt Modes

7-4-4Using Interval Timer Interrupts

Interval Timer Interrupts

Section

Interval Timer Interrupts

7-4-5Application Example

Pulse Inputs

Specifications

7-5-1

Applicable Models

Pulse Inputs

Section

7-5-4Pulse Input Specifications

Pulse InputsSection

Pulse Inputs

Section

Minimum response pulse

At 50 kHz

Phases A and B

Phase Z

7-5-6

7-5-7

Input Signal Type and Count Mode

Phase Differential Inputs

Phase Differential Input Operation

Pulse Inputs

Reset Methods

Pulse Inputs

Section

Counter Operation Numeric Ranges

Phase-ZSignal Reset Input and Software Reset

Software Reset

Pulse Inputs

Section

Range Comparison Method

Pulse Inputs

Section

Monitoring High-speedCounter Movement Mode

Pulse Inputs

Section

High-speedCounter Movement Mode 1 Specifications

Pulse Inputs

Section

Monitoring a High-speedCounter’s Frequency Mode

Frequency Measurement Mode 2 Specifications

Pulse Inputs

Section

Latching a High-speedCounter’s PV

7-5-9Pulse Input Function Procedures

High-speedCounter Procedure

Pulse Inputs

Section

Section

Mode 1 Procedure

Pulse Inputs

Mode 2 Procedure

Procedure

Procedure

Pulse Inputs

Pulse Inputs

Section

Example

High-speed Counter PV

Pulse Inputs

Section

Example High-speedCounter Range Comparison

Bit Pattern Output

P_On

Pulse Inputs

Section

Example Latching High-speed Counter PV

Pulse Inputs

Section

Pulse Outputs

7-6-1

7-6-2

Pulse OutputsSection

Acceleration/ decelera

7-6-3

Pulse OutputsSection

Pulse Output Specifications

7-6-4

Pulse Outputs

Section

7-6-5

Applicable Instructions

Pulse OutputsSection

Instructions Ineffective during Pulse Output

7-6-6

Pulse Output Function Details

Pulse OutputsSection

Overview

Pulse Outputs

Section

Pulse output

Description

Procedure

Settings

Pulse Outputs

Section

Indepen

Pulse Outputs

Section

Precautions when Using Pulse Outputs

Pulse Outputs

Section

Target frequency

7-6-7 One-shotPulse Output Function

Pulse Outputs

Section

Formula

Section

One-shotPulse Output Specifications

Pulse Outputs

Section

7-6-8Time Measurement with the Pulse Counter

Pulse Outputs

Section

Pulse Counter Timer Specifications

Pulse Outputs

Pulse Outputs

Section

Linear Mode Operation

Frequency speed Target value Target value

3.00

Pulse Outputs

Section

Section

Circular Mode Operation

Single-rotationspeed control pattern

High-speedregion Low-speed 0region

Setting the

Pulse Outputs

Section

Speed-changeCycle

Setting the Pulse Output Direction Priority Mode

Pulse Outputs

Section

Pulse Output Direction Priority Mode

Pulse Outputs with Acceleration/Deceleration

Pulse Outputs

Section

Procedure

Pulse Outputs

Section

Electronic Cam Control Functions

Pulse Outputs

Section

Pulse Counter Timer Function STIM980

Pulse Outputs

Section

One-shotPulse Output STIM980

Section

7-6-14Pulse Output Function Examples

Pulse Outputs

Pulse Outputs

Section

Changing the Frequency in Steps

Accelerating the Frequency at a Fixed Rate

Pulse Outputs

Section

Specified number of pulses

Speed reaches 0 while the remaining

P_On Always ON Flag P_On Always ON Flag

Pulse Outputs

Section

Pulse Outputs

Section

Pulse Counter Time Measurement Timer Example

7-6-15Pulse Output Starting Conditions

Pulse Outputs

Section

Pulse Outputs

Section

Pulse Outputs

Section

PULS886 Absolute Pulse Output in Progress

Pulse Output Operation

Pulse Outputs

Section

PLS2887

Cases 1, 2, and

Pulse Outputs

Section

Cases 6, 8, 9, and

Cases 7, 11, 12,

Section

7-7-1Applicable Models

7-7-2Overview

Serial Data Specification

7-7-3Data Format of Absolute Encoder Output

Section

Data Format

7-7-4Counter Operation

Section

Counting Operation Counter Operation Details

Absolute Linear CW−

Absolute Linear Counter Absolute Circular Counter

7-7-6Absolute Present Value

Section

Section

7-7-7Absolute Present Value Preset

7-7-8Absolute Offset Preset

7-7-9

System Setup

Related Areas

Section

Auxiliary Area

Note Refer to 7-7-6Absolute Present Value

Section

A606

Step 1 Required: Setting

Setting the Pulse Input Method

Setting the Input Pulse Counting Speed

Setting the Counter Operation

Offset Preset

Step 4 Required Absolute Present Value Preset

Section

Step 3 as Needed: Origin Compensation Absolute

Section

Program Description

Section

0.00

Section

000005

7-8Virtual Pulse Output Function

7-8-1

7-8-2

Virtual Pulse Output FunctionSection

T First Word of Setting Table

Virtual Pulse Output FunctionSection

Overview

Operands

Description

Virtual Pulse Output Function

Section

7-9Analog Input Functions

Positioning or Speed Control Using a Virtual Axis

7-9-1

7-9-2

Section

Sensor pressure, displacement, etc

Analog Input Functions

Analog Input FunctionsSection

Analog Input Function Specifications

7-9-3

Related Areas and Settings

System Setup

Settings

Time when setting

Analog Input Functions

Section

Auxiliary Area

A550

A562

Analog Input Functions

Section

A570

Analog Input Functions

Section

Signal Range: −10 to 10 Signal Range: 0 to 10

7-9-5Applicable Instructions

7-9-6A/D Conversion Value

Analog Input Functions

Signal Range: 1 to 5 V and 4 to 20 mA

Signal Range: 0 to 5

Analog Input Functions

Section

Analog Input Functions

Section

Example

Application Example

7-10

Analog Outputs

7-10-1

7-10-2

7-10-3Analog Output Function Specifications

Analog OutputsSection

Analog Outputs

put Tab Page − Output

CPU standby status

Analog Outputs

Section

Specified Output Values and Analog Output Signals

Analog Outputs

Section

END Refreshing With Immediate Refreshing

Section

7-10-5Procedure

Analog Outputs

Analog Outputs

Section

Outputting the Analog Output Value Stored

in the Auxiliary Area

Analog Outputs

Section

Analog Outputs

Section

SECTION Connecting the CX-Programmer

CX-Programmer

CX-ProgrammerSection

8-2Connecting the CX-Programmer

Connecting the CX-Programmer

Connecting to the Peripheral Port

Connecting to the RS-232CPort

Connecting the CX-Programmer

Connecting to the Peripheral Port

Connection Diagram

Section

Connecting the CX-Programmer

Connecting to the RS-232CPort

Using an RS-232CCable

Section

Section

8-2-2 CX-ProgrammerConnecting Cables

Connecting the CX-Programmer

Section

Connecting the CX-Programmer

Connecting an RS-232CCable to the RS-232CPort

Connecting the CX-Programmer

Section

SECTION Error Processing

9-1Error Log

Error Log

Errors Generated by FAL006/FALS007

Error Log Structure

Error Processing

Error Categories

9-2-2Error Information

Error ProcessingSection

Error Codes

Error Processing

9-2-3

Section

Section

9-2-4Error Processing Flowchart

Error Processing

Error Processing

CPU Errors

Fatal Errors

Section

Section

Error Processing

message and related Auxiliary Area flags/words and correct the cause of the error

Error Processing

Fatal Errors

Error

Error

Error Processing

Non-fatalErrors

Non-fatalErrors

Section

Section

Error Processing

Other Errors

Section

9-2-6Power Supply Check

Error Processing

9-2-7Memory Error Check

9-2-8Program Error Check

Error Processing

Section

9-2-9Cycle Time Overrun Error Check

9-2-10System Setup Error Check

Error Processing

Section

9-2-11I/O Setting Error Check

Error Processing

I/O Setting Error occurred

Section

Section

Error Processing

9-2-12I/O Check

Troubleshooting Problems in Modules

Troubleshooting Problems in Modules

Coordinator Module Errors

9-2-13Environmental Conditions Check

Troubleshooting Problems in Modules

Motion Control Module Errors

Input Errors

Section

Section

Troubleshooting Problems in Modules

Output Errors

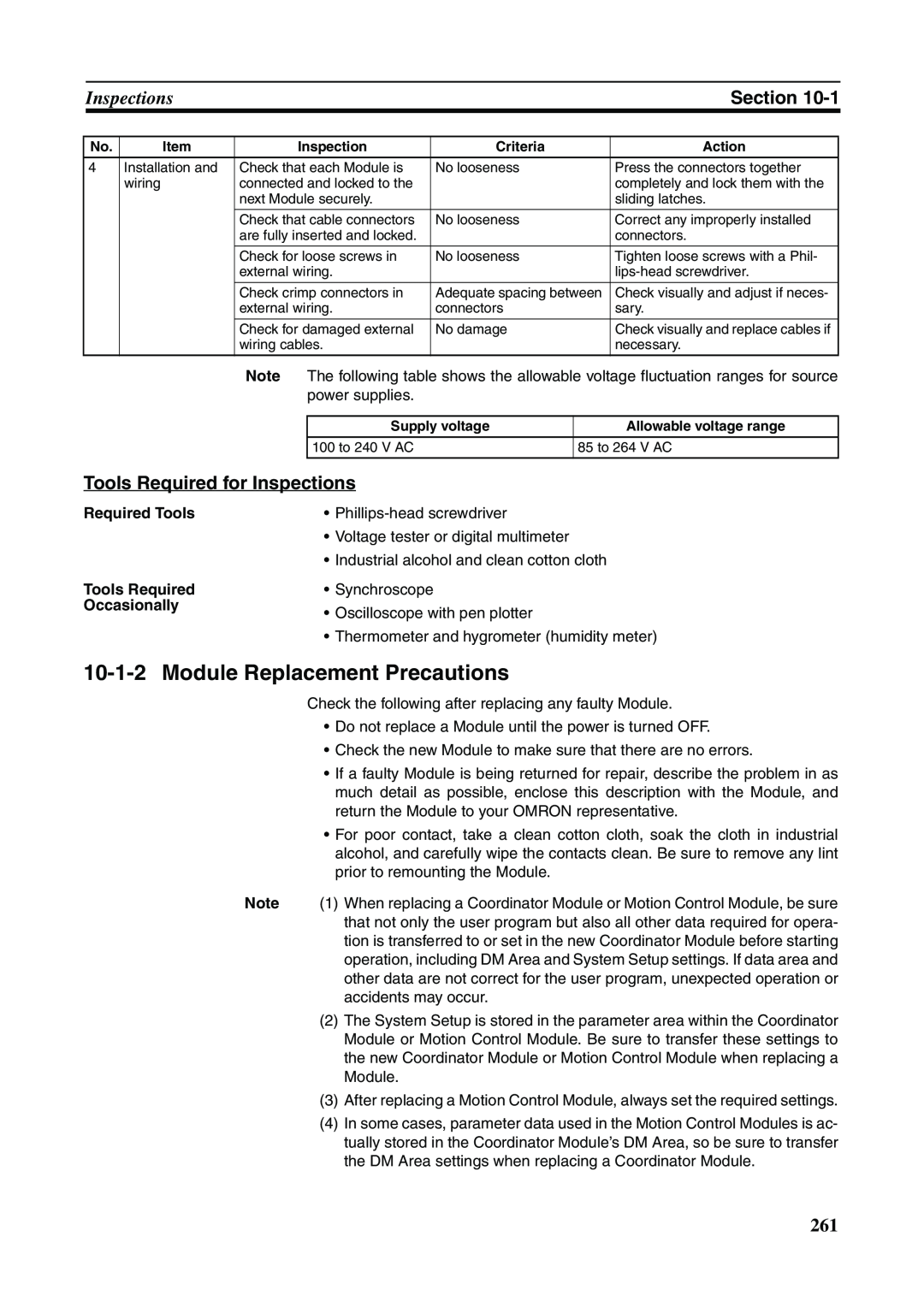

Inspection and Maintenance

SECTION

Module Replacement Precautions

10-1Inspections

10-1Inspections

10-1-1Inspection Points

InspectionsSection

Inspection Points for Periodic Inspections

Inspections

Section

Tools Required for Inspections

Required Tools

Inspections

Section

Appendix A

Programming Programs and Tasks

Subroutines

Using Normal Subroutines

What Are Subroutines?

Programming

Using Subroutines That Pass Parameters

Programming

Appendix A

Execution with Subroutine Input Condition Flags

Programming

Appendix A

JSB982 Operation

Address

Programming

Appendix A

Application Examples

Without Macro Function

Programming

Appendix A

Execution with Subroutine Input Condition Flags

Main Program

Basic Information on Programming

Power Flow

Programming

Appendix A

Programming

Appendix A

Flags

Operands

Instruction Location and Input Conditions

Addressing I/O Memory Areas

Programming

Appendix A

Specifying Operands

Programming

Appendix A

Operand

Programming

Appendix A

Operand

Description

Operand

Programming

Appendix A

Programming

Appendix A

Upper 4 bits

Lower 4 bits

Data Formats

Programming

Appendix A

Note Signed Binary Data

Programming

Appendix A

Complements

Two’s Complements

ProgrammingAppendix A

Note Signed BCD Data

Instruction Variations

Input Conditions

Programming

Appendix A

Upwardly differentiated input instruction

Programming

Appendix A

Programming Precautions

Using Condition Flags

Condition Flags

Programming

1.Using Execution Results in NC and NO Inputs

Programming

Appendix A

Instruction A

Programming

Appendix A

CMP 0010 D00100 Reflects CMP execution results

MOV 1 0200 D00200 Reflects MOV execution results

Error Flag

Programming

Appendix A

Main Conditions Turning ON Condition Flags

Programming

Appendix A

Equals Flag

Carry Flag

Special Program Sections

Programming

Appendix A

Instruction Combinations

Programming

Appendix A

Instructions Not Allowed in Subroutines

Note Block Program Sections

Computing the Cycle Time

FQM1 Operation Flowchart

Programming

Appendix A

Overview of Cycle Time Calculations

Programming

Appendix A

Coordinator Module

Programming

Appendix A

Module I/O Refresh Times

Programming

Appendix A

Cyclic Refresh Time in the Coordinator Module

Example of Calculating the Cycle Time

Online Editing Cycle Time Extension

Programming

Appendix A

Response Time

Programming

Appendix A

Coordinator Module I/O Response Time

Programming

Appendix A

Motion Control Module I/O Response Time

Minimum I/O Response Time General-purposeI/O 0 to

Programming

Appendix A

Motion Control Module Interrupt Response Times

Calculation Example

Programming

Appendix A

Motion Control Module Interrupt Processing Times

Scheduled Interrupt Task

Programming

Appendix A

Processing Time

Interrupt Response Time Calculation Example

Appendix A

2When using interrupt tasks frequently, be sure to consider the time required for interrupt processing and its affect on the overall system

Programming

Appendix B

I/O Memory Overview of I/O Memory

I/O Memory

Parameter Area

I/O Memory Structure

Coordinator Module

I/O Memory

Appendix B

Appendix B

Motion Control Modules

I/O Memory

CIO Area

I/O Memory

Appendix B

I/O Bit Area: CIO 0000 and CIO

I/O Memory

Appendix B

Synchronous Data Link Bit Area: CIO 0200 to

Serial PLC Link Bit Area CIO 0080 to CIO

Auxiliary Area: A000 to A649 A000.00 to A649.15

Temporary Relay Area TR

Refreshing Using the IORF097 Instruction

I/O Memory

Appendix B

Timer Area

I/O Memory

Appendix B

Counter Area

I/O Memory

Data Memory DM Area

Condition Flags

Binary-modeAddressing @D

BCD-modeAddressing *D

Using the Condition Flags

symbol

I/O Memory

Appendix B

Clock Pulses

Using the Clock Pulses

I/O Memory

Appendix B

Parameter Area

System Setup

I/O Memory

Appendix B

System Setup, Auxiliary Area Allocations

Overview of System Setups

System Setup in the Coordinator Module

Appendix C

Appendix C

Peripheral Port Settings for Host Link

Communications Settings

Standard/Custom Setting

Appendix C

Peripheral Port Settings for NT Link

Standard/Customer Setting

Appendix C

Host Link Unit Number

RS-232CPort Settings for Host Link

Appendix C

Baud Rate

Serial Communications Mode

RS-232CPort Settings for NT Link

RS-232CPort Settings for Peripheral Bus ToolBus

Standard/Custom Setting

Appendix C

Send Delay

Appendix C

Baud Rate

Serial Communications Mode

RS-232CPort Settings for PLC Link PC Link Slave

Appendix C

Start Code and End Code

Number of Received Bytes

RS-422APort Settings CX-Programmer:Drive Tab Page

RS-422APort Settings for Serial Gateway

Standard/Custom Setting

Send Delay Time

Peripheral Service Time

Appendix C

Start Code and End Code

Number of Received Bytes

System Setup in Motion Control Modules

CX-Programmer:Module Settings Tab Page

Appendix C

CX-Programmer:Cycle Time Tab Page

FQM1-MMP21Motion Control Modules with Pulse I/O

CX-Programmer:Pulse Input Tab Page

Appendix C

CX-Programmer:Pulse Output Tab Page

Pulse Output

Function Details

When setting

FQM1-MMA21Motion Control Modules with Analog I/O

Appendix C

CX-Programmer:Pulse Input Tab Page

Details on System Setup Settings

Peripheral Port Settings

RS-232CPort Settings Host Link Port

Appendix C

Appendix C

Constant Cycle Time

Watch Cycle Time

Messages Sent and Received with No-protocolMode

Appendix C

Fixed Peripheral Servicing Time

The default value for each servicing process is 6.25% of the last cycle’s cycle time. In general, it is rec- ommended that the default value be used. Set a uniform servicing time only when peripheral servicing is being delayed because each service process is being spread over several cycles

Appendix C

Auxiliary Area Allocations by Function

Appendix C

Allocations That Are the Same for All Modules

FQM1-MMP21Motion Control Modules with Pulse I/O

Appendix C

A608

Appendix C

Address

Bits

Name

Appendix C

A610

Appendix C

A611

Appendix C

A620 to

Appendix C

A626

Appendix C

FQM1-MMA21Motion Control Modules with Analog I/O

Address

Bits

Appendix C

A562

Appendix C

A564

flows/underflows are checked when the PV is read

Appendix C

Note For a Linear Counter, high-speedcounter over

change in the PV of the high-speedcounter over

Appendix C

Address

Bits

Name

Appendix C

Address

Bits

Name

Appendix C

A610

Input Interrupts

Allocations Related to Built-inInputs

Appendix C

Program Error Flags

Other Error Flags and Bits

Error Log and Error Code

Appendix C

FAL/FALS Errors

Memory Errors

System Setup

I/O Errors

Appendix C

Communications

Other

Peripheral Port

Built-inI/O Allocations

Allocations Directly Related to Instructions

Appendix C

RS-232CPort

Inputs 40-pin General-purposeI/O Connector

Outputs 40-pin General-purposeI/O Connector

Inputs 26-pin General-purposeI/O Connector

Outputs 26-pin General-purposeI/O Connector

Auxiliary Area Allocations in Order of Address

Appendix D

Auxiliary Area Allocations

Auxiliary Area Allocations

Appendix D

A414

Auxiliary Area Allocations

Appendix D

A520

Auxiliary Area Allocations

Appendix D

A559

Auxiliary Area Allocations

Appendix D

A570

Auxiliary Area Allocations

Appendix D

A606 to

Auxiliary Area Allocations

Appendix D

A610

Auxiliary Area Allocations

Appendix D

A612

Auxiliary Area Allocations

Appendix D

A626

Auxiliary Area Allocations

Appendix D

Error Codes and Error Flags

Error Log Area: A100 to A199

Detailed Explanations on the Auxiliary Area

Auxiliary Area Allocations

Memory Configuration

FQM1 Memory Addresses

Auxiliary Area Allocations

Appendix D

Memory Map

Auxiliary Area AllocationsAppendix D

Auxiliary Area Allocations

Appendix D

Sequence Input Instructions

Sequence Output Instructions

Timer and Counter Instructions

Auxiliary Area Allocations

Appendix D

Sequence Control Instructions

Data Movement Instructions

Auxiliary Area Allocations

Appendix D

Auxiliary Area Allocations

Appendix D

Data Shift Instructions

Increment/Decrement Instructions

Appendix D

Symbol Math Instructions

Auxiliary Area Allocations

Auxiliary Area Allocations

Appendix D

Conversion Instructions

Logic Instructions

Auxiliary Area Allocations

Appendix D

Special Math Instructions

Floating-pointMath Instructions

Auxiliary Area Allocations

Appendix D

Table Data Processing Instructions

Data Control Instructions

Auxiliary Area Allocations

Appendix D

Interrupt Control Instructions

High-speedCounter and Pulse Output Instructions

Auxiliary Area Allocations

Appendix D

Step Instructions

I/O Refresh Instruction

Auxiliary Area Allocations

Appendix D

Serial Communications Instructions

Debugging Instructions

Branching

Auxiliary Area Allocations

Appendix D

Auxiliary Area Allocations

Appendix D

Index

Index

Index

Index

Index

Page

Index

Index

Peripheral Devices, 6 peripheral port

Index

Index

Servo Drivers

Index

Index

Revision History

Cat. No. O010-E1-01

Page

OMRON CORPORATION

FA Systems Division H.Q 66 Matsumoto

Mishima-city,Shizuoka Japan

Tel: 8155-977-9181/Fax:

Certain Precautions on Specifications and Use

Terms and Conditions of Sale

OMRON ELECTRONICS LLC

1 Commerce Drive Schaumburg, IL

OMRON CANADA, INC

885 Milner Avenue Toronto, Ontario M1B