Caution: Do not turn on the Air Compressor at this time.

Oiler and Filter Connection

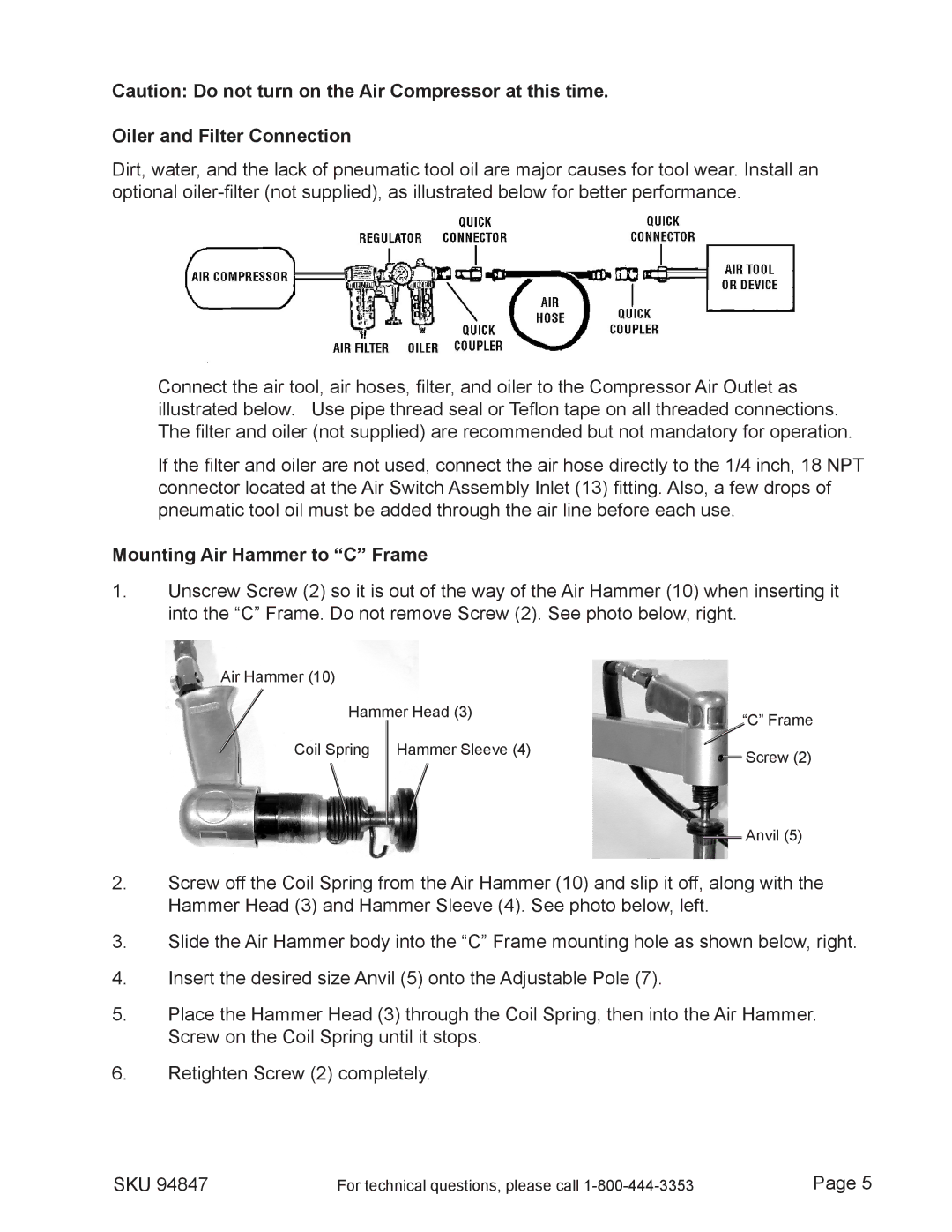

Dirt, water, and the lack of pneumatic tool oil are major causes for tool wear. Install an optional

Connect the air tool, air hoses, filter, and oiler to the Compressor Air Outlet as illustrated below. Use pipe thread seal or Teflon tape on all threaded connections. The filter and oiler (not supplied) are recommended but not mandatory for operation.

If the filter and oiler are not used, connect the air hose directly to the 1/4 inch, 18 NPT connector located at the Air Switch Assembly Inlet (13) fitting. Also, a few drops of pneumatic tool oil must be added through the air line before each use.

Mounting Air Hammer to “C” Frame

1.Unscrew Screw (2) so it is out of the way of the Air Hammer (10) when inserting it into the “C” Frame. Do not remove Screw (2). See photo below, right.

Air Hammer (10)

Hammer Head (3) |

| “C” Frame | ||

Coil Spring | Hammer Sleeve (4) |

| ||

| Screw (2) | |||

|

|

|

| |

|

|

|

| Anvil (5) |

|

|

|

| |

|

|

|

| |

2.Screw off the Coil Spring from the Air Hammer (10) and slip it off, along with the Hammer Head (3) and Hammer Sleeve (4). See photo below, left.

3.Slide the Air Hammer body into the “C” Frame mounting hole as shown below, right.

4.Insert the desired size Anvil (5) onto the Adjustable Pole (7).

5.Place the Hammer Head (3) through the Coil Spring, then into the Air Hammer. Screw on the Coil Spring until it stops.

6.Retighten Screw (2) completely.

SKU 94847 | For technical questions, please call | Page |