OPERATING INSTRUCTIONS

To Start The Compressor:

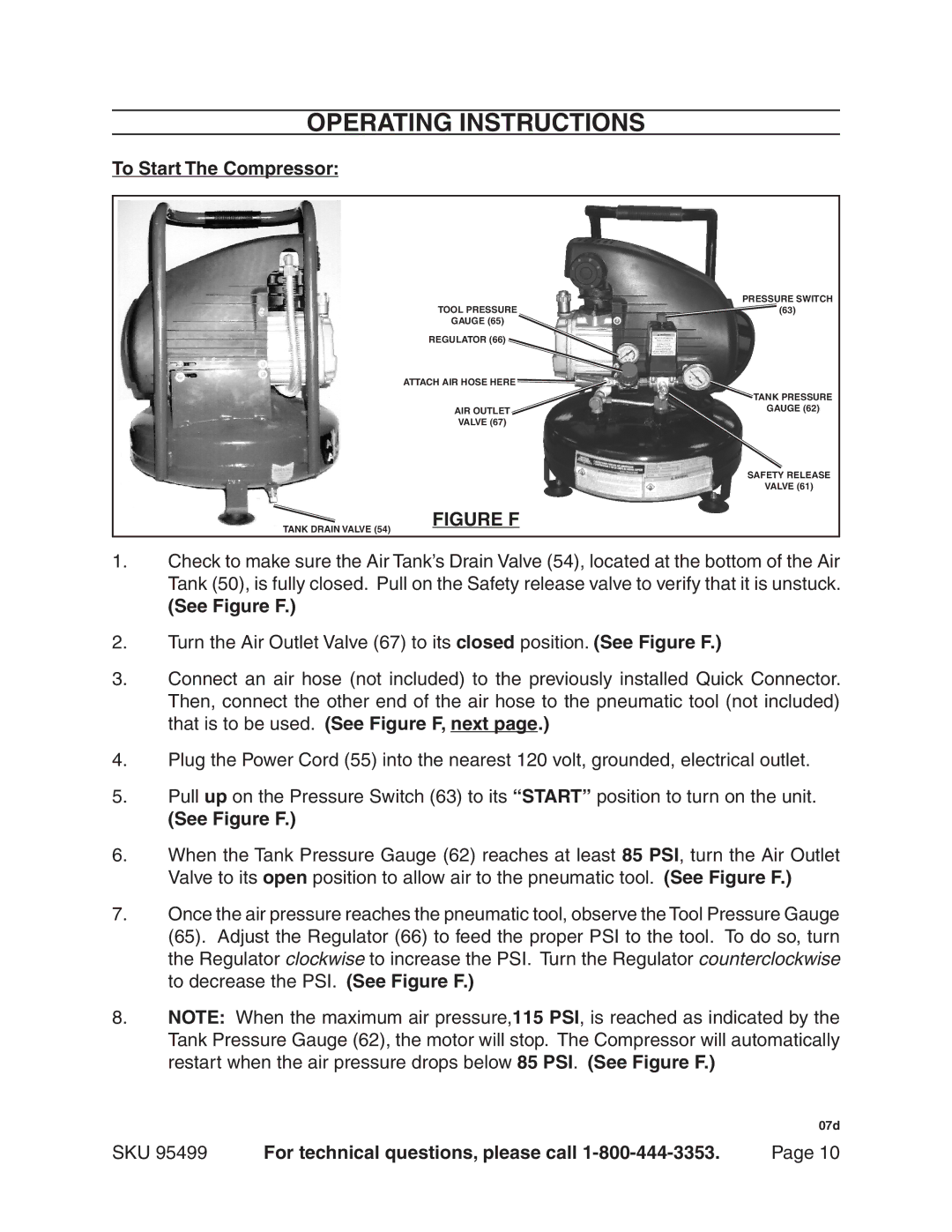

PRESSURE SWITCH

TOOL PRESSURE![]() (63)

(63)

GAUGE (65)

REGULATOR (66)

ATTACH AIR HOSE HERE ![]()

TANK DRAIN VALVE (54)

TANK PRESSURE

AIR OUTLETGAUGE (62) VALVE (67)

SAFETY RELEASE

VALVE (61)

FIGURE F

1.Check to make sure the Air Tank’s Drain Valve (54), located at the bottom of the Air Tank (50), is fully closed. Pull on the Safety release valve to verify that it is unstuck.

(See Figure F.)

2.Turn the Air Outlet Valve (67) to its closed position. (See Figure F.)

3.Connect an air hose (not included) to the previously installed Quick Connector. Then, connect the other end of the air hose to the pneumatic tool (not included) that is to be used. (See Figure F, next page.)

4.Plug the Power Cord (55) into the nearest 120 volt, grounded, electrical outlet.

5.Pull up on the Pressure Switch (63) to its “START” position to turn on the unit.

(See Figure F.)

6.When the Tank Pressure Gauge (62) reaches at least 85 PSI, turn the Air Outlet Valve to its open position to allow air to the pneumatic tool. (See Figure F.)

7.Once the air pressure reaches the pneumatic tool, observe the Tool Pressure Gauge (65). Adjust the Regulator (66) to feed the proper PSI to the tool. To do so, turn the Regulator clockwise to increase the PSI. Turn the Regulator counterclockwise to decrease the PSI. (See Figure F.)

8.NOTE: When the maximum air pressure,115 PSI, is reached as indicated by the Tank Pressure Gauge (62), the motor will stop. The Compressor will automatically restart when the air pressure drops below 85 PSI. (See Figure F.)

07d

SKU 95499 | For technical questions, please call | Page 10 |