16.IMPORTANT: To avoid damage to the internal gears, do not change the rotation (forward/reverse) of the tool when accelerating the Engine. Change the rotation only when the Engine is at idle.

17.Squeeze the Throttle Assembly (102) for high speed to loosen or tighten the bolt or nut. (See Figure A.)

18.Once the bolt or nut is loosened or tightened, release the Throttle Assembly (102) to allow the Engine to return to idle speed. (See Figure A.)

19.Slide the Stop Button (103) downward to its “STOP” position. (See Figure A.)

20.Place the Impact Wrench on a firm stand or solid floor. Then, set the Gear Change Lever (233D) to its “NEUTRAL” position. (See Figure A.)

21.Allow the Engine of the Impact Wrench to completely cool. Then store the tool in a clean, dry, safe location out of reach of children and other unauthorized people.

INSPECTION, MAINTENANCE, AND CLEANING

1.![]() WARNING! Always make sure the Stop Button (103) is in its “STOP” position and the Spark Plug (3A) is removed prior to performing any service,

WARNING! Always make sure the Stop Button (103) is in its “STOP” position and the Spark Plug (3A) is removed prior to performing any service,

maintenance, or cleaning of the Impact Wrench.

2.Before each use: Inspect the general condition of the Impact Wrench. Check misalignment or binding of moving parts, cracked or broken parts, and any other condition that may affect the safe operation of the tool. If abnormal noise or vibration occurs, have the problem corrected before further use.

Do not use damaged equipment.

3.Impact unit and Gear Case (209D) maintenance: Prior to each use, check the Gear Oil Port (210D) for proper gear oil level. If necessary, refill the Gear Case with #10 gear oil. (See page 8 and Figure C.)

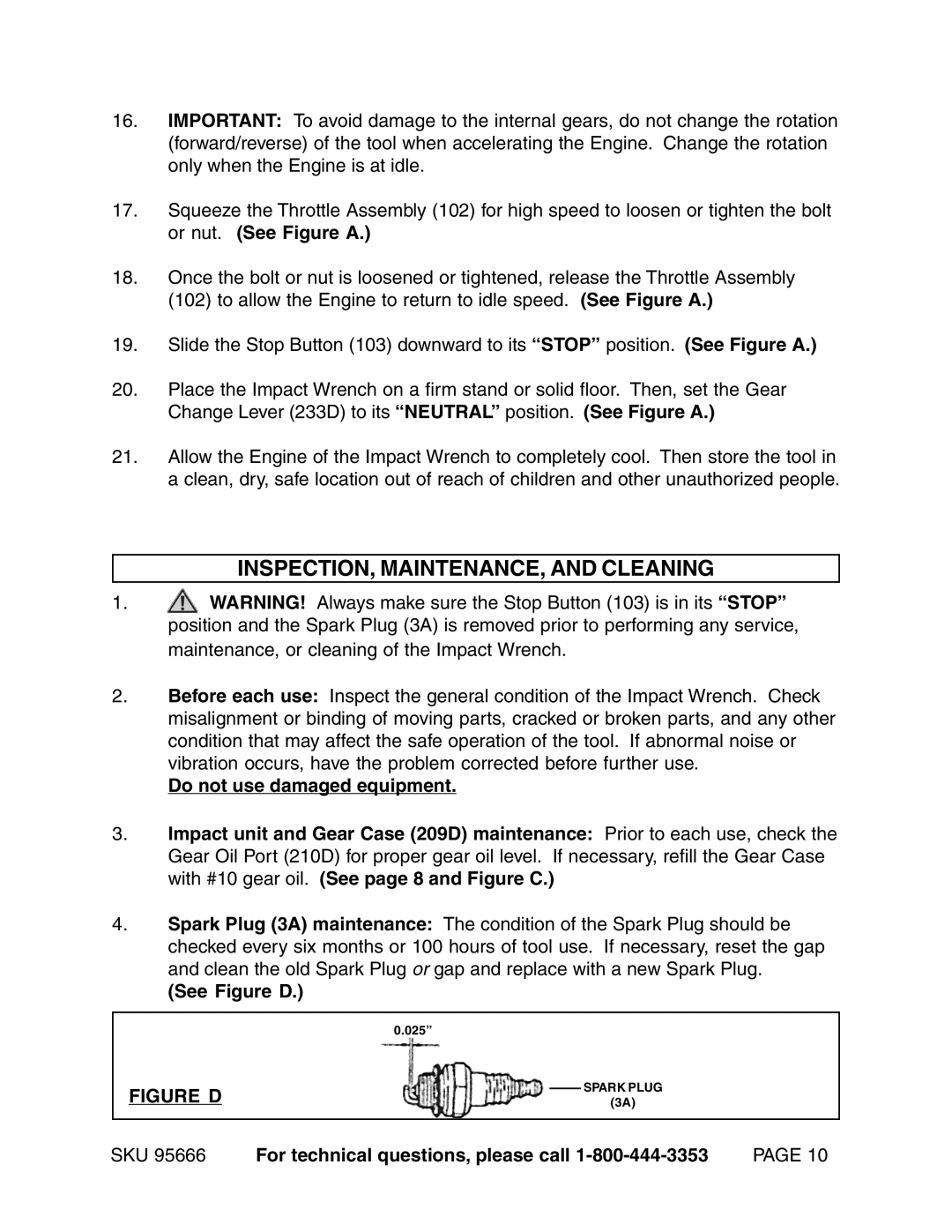

4.Spark Plug (3A) maintenance: The condition of the Spark Plug should be checked every six months or 100 hours of tool use. If necessary, reset the gap and clean the old Spark Plug or gap and replace with a new Spark Plug.

(See Figure D.)

0.025”

FIGURE D

SPARK PLUG

(3A)

SKU 95666 For technical questions, please call