of the wheel, reference markings

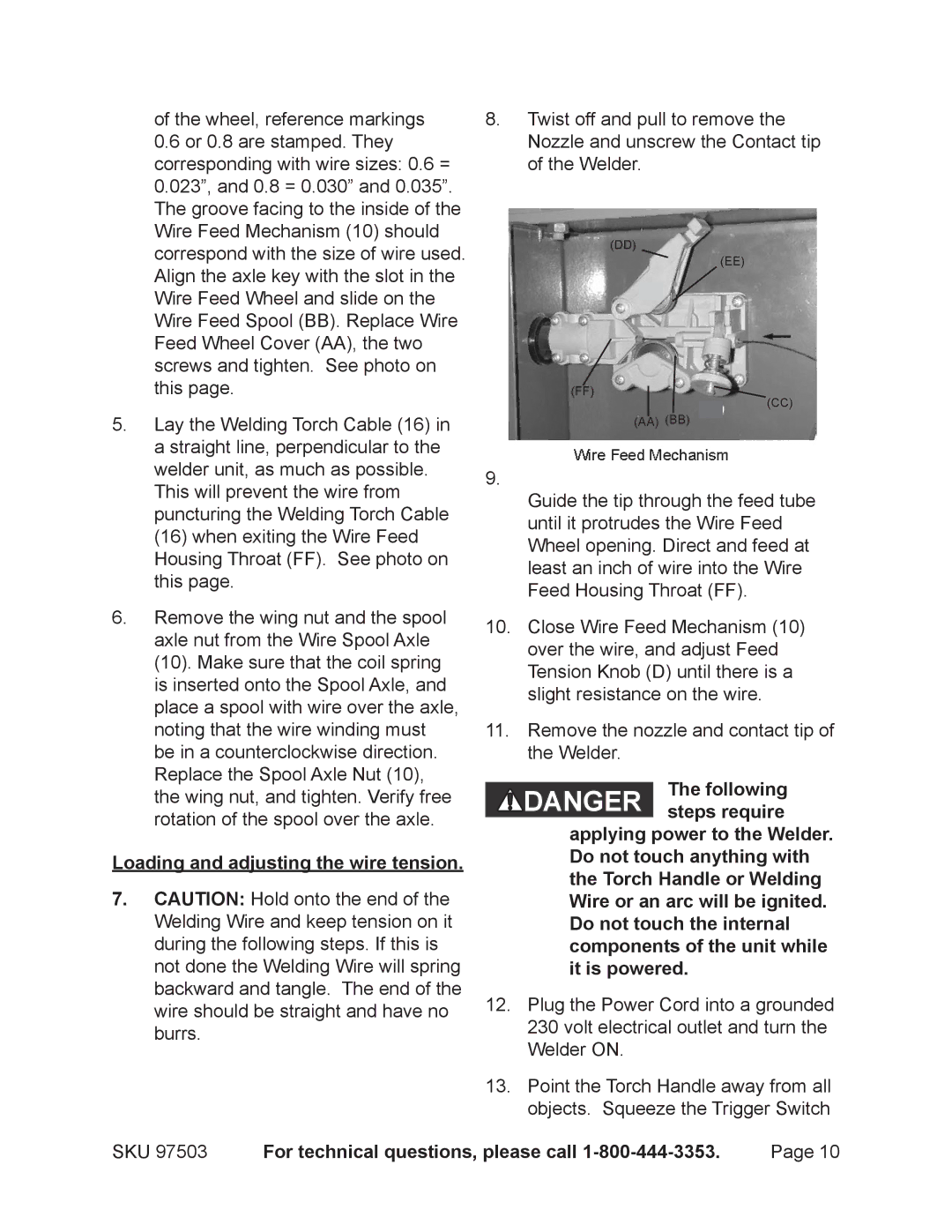

0.6 or 0.8 are stamped. They corresponding with wire sizes: 0.6 = 0.023”, and 0.8 = 0.030” and 0.035”. The groove facing to the inside of the Wire Feed Mechanism (10) should correspond with the size of wire used. Align the axle key with the slot in the Wire Feed Wheel and slide on the Wire Feed Spool (BB). Replace Wire Feed Wheel Cover (AA), the two screws and tighten. See photo on this page.

5.Lay the Welding Torch Cable (16) in a straight line, perpendicular to the welder unit, as much as possible.

This will prevent the wire from puncturing the Welding Torch Cable (16) when exiting the Wire Feed Housing Throat (FF). See photo on this page.

6.Remove the wing nut and the spool axle nut from the Wire Spool Axle (10). Make sure that the coil spring is inserted onto the Spool Axle, and place a spool with wire over the axle, noting that the wire winding must be in a counterclockwise direction. Replace the Spool Axle Nut (10), the wing nut, and tighten. Verify free rotation of the spool over the axle.

Loading and adjusting the wire tension.

7.CAUTION: Hold onto the end of the Welding Wire and keep tension on it during the following steps. If this is not done the Welding Wire will spring backward and tangle. The end of the wire should be straight and have no burrs.

8.Twist off and pull to remove the Nozzle and unscrew the Contact tip of the Welder.

(DD)

(EE)

(FF)

(CC)

(AA) (BB)

9.

Guide the tip through the feed tube until it protrudes the Wire Feed Wheel opening. Direct and feed at least an inch of wire into the Wire Feed Housing Throat (FF).

10.Close Wire Feed Mechanism (10) over the wire, and adjust Feed Tension Knob (D) until there is a slight resistance on the wire.

11.Remove the nozzle and contact tip of the Welder.

| The following | |

Danger | ||

steps require | ||

|

applying power to the Welder. Do not touch anything with the Torch Handle or Welding Wire or an arc will be ignited. Do not touch the internal components of the unit while it is powered.

12.Plug the Power Cord into a grounded 230 volt electrical outlet and turn the Welder ON.

13.Point the Torch Handle away from all objects. Squeeze the Trigger Switch

SKU 97503 | For technical questions, please call | Page 10 |