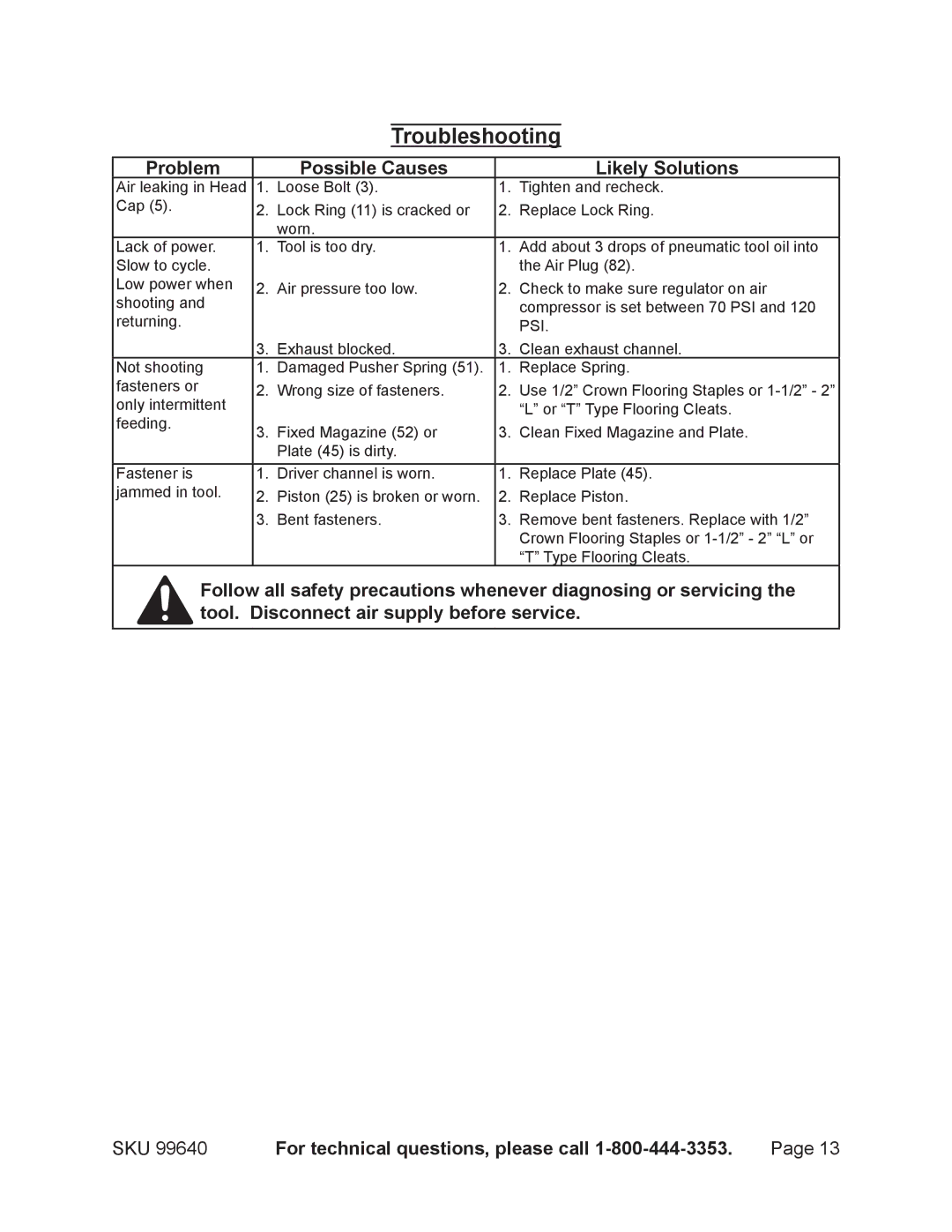

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Air leaking in Head | 1. | Loose Bolt (3). | 1. | Tighten and recheck. |

Cap (5). | 2. | Lock Ring (11) is cracked or | 2. | Replace Lock Ring. |

|

| worn. |

|

|

Lack of power. | 1. | Tool is too dry. | 1. | Add about 3 drops of pneumatic tool oil into |

Slow to cycle. |

|

|

| the Air Plug (82). |

Low power when | 2. | Air pressure too low. | 2. | Check to make sure regulator on air |

shooting and |

|

|

| compressor is set between 70 PSI and 120 |

returning. |

|

|

| PSI. |

| 3. | Exhaust blocked. | 3. | Clean exhaust channel. |

Not shooting | 1. | Damaged Pusher Spring (51). | 1. | Replace Spring. |

fasteners or | 2. | Wrong size of fasteners. | 2. | Use 1/2” Crown Flooring Staples or |

only intermittent |

|

|

| “L” or “T” Type Flooring Cleats. |

feeding. | 3. | Fixed Magazine (52) or | 3. | Clean Fixed Magazine and Plate. |

| ||||

|

| Plate (45) is dirty. |

|

|

|

|

|

|

|

Fastener is | 1. | Driver channel is worn. | 1. | Replace Plate (45). |

jammed in tool. | 2. | Piston (25) is broken or worn. | 2. | Replace Piston. |

| 3. | Bent fasteners. | 3. | Remove bent fasteners. Replace with 1/2” |

|

|

|

| Crown Flooring Staples or |

|

|

|

| “T” Type Flooring Cleats. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

SKU 99640 | For technical questions, please call | Page 13 |