Refrigeration Piping

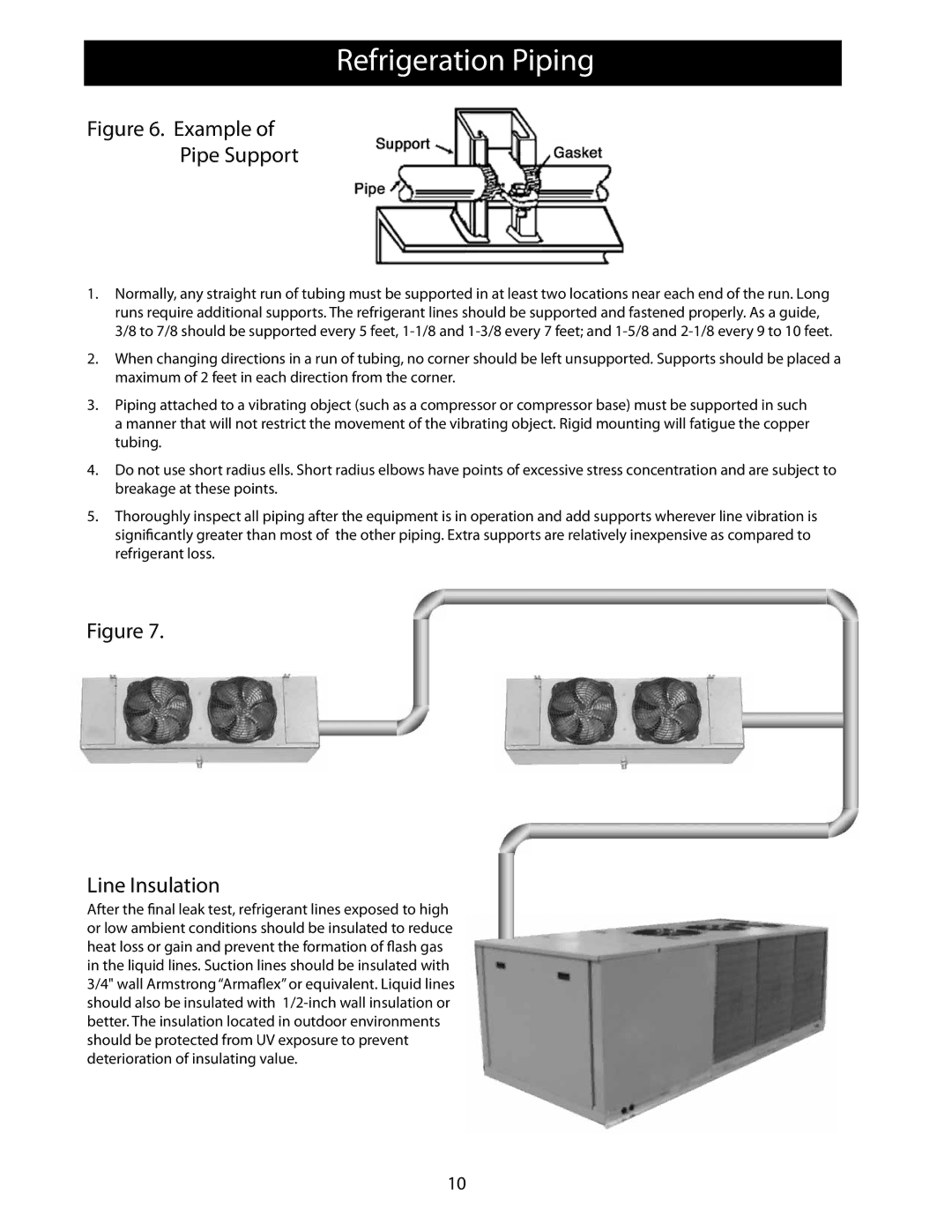

Figure 6. Example of

Pipe Support

1.Normally, any straight run of tubing must be supported in at least two locations near each end of the run. Long runs require additional supports. The refrigerant lines should be supported and fastened properly. As a guide, 3/8 to 7/8 should be supported every 5 feet,

2.When changing directions in a run of tubing, no corner should be left unsupported. Supports should be placed a maximum of 2 feet in each direction from the corner.

3.Piping attached to a vibrating object (such as a compressor or compressor base) must be supported in such a manner that will not restrict the movement of the vibrating object. Rigid mounting will fatigue the copper tubing.

4.Do not use short radius ells. Short radius elbows have points of excessive stress concentration and are subject to breakage at these points.

5.Thoroughly inspect all piping after the equipment is in operation and add supports wherever line vibration is significantly greater than most of the other piping. Extra supports are relatively inexpensive as compared to refrigerant loss.

Figure 7.

Line Insulation

After the final leak test, refrigerant lines exposed to high or low ambient conditions should be insulated to reduce heat loss or gain and prevent the formation of flash gas in the liquid lines. Suction lines should be insulated with 3/4" wall Armstrong “Armaflex” or equivalent. Liquid lines should also be insulated with

10