341 specifications

Henny Penny 341 is a state-of-the-art pressure fryer that marks a significant advancement in commercial kitchen technology. Designed for high-volume production, it caters primarily to the fast-food and restaurant industries, where efficiency and food quality are paramount.One of the standout features of the Henny Penny 341 is its ability to deliver perfectly cooked fried foods with a crispy exterior and juicy interior. This is achieved through its innovative pressure-frying technology. The fryer uses an airtight cooking chamber, allowing the oil to reach high temperatures without excessive oil absorption in the food, making it healthier for consumers and more cost-effective for operators.

The Henny Penny 341 is designed with user-friendliness in mind. It comes equipped with a straightforward digital control panel that allows operators to set precise cooking times and temperatures, ensuring consistency in food quality. The programmable features enable users to save and recall multiple recipes, which is ideal for establishments that offer a diverse menu.

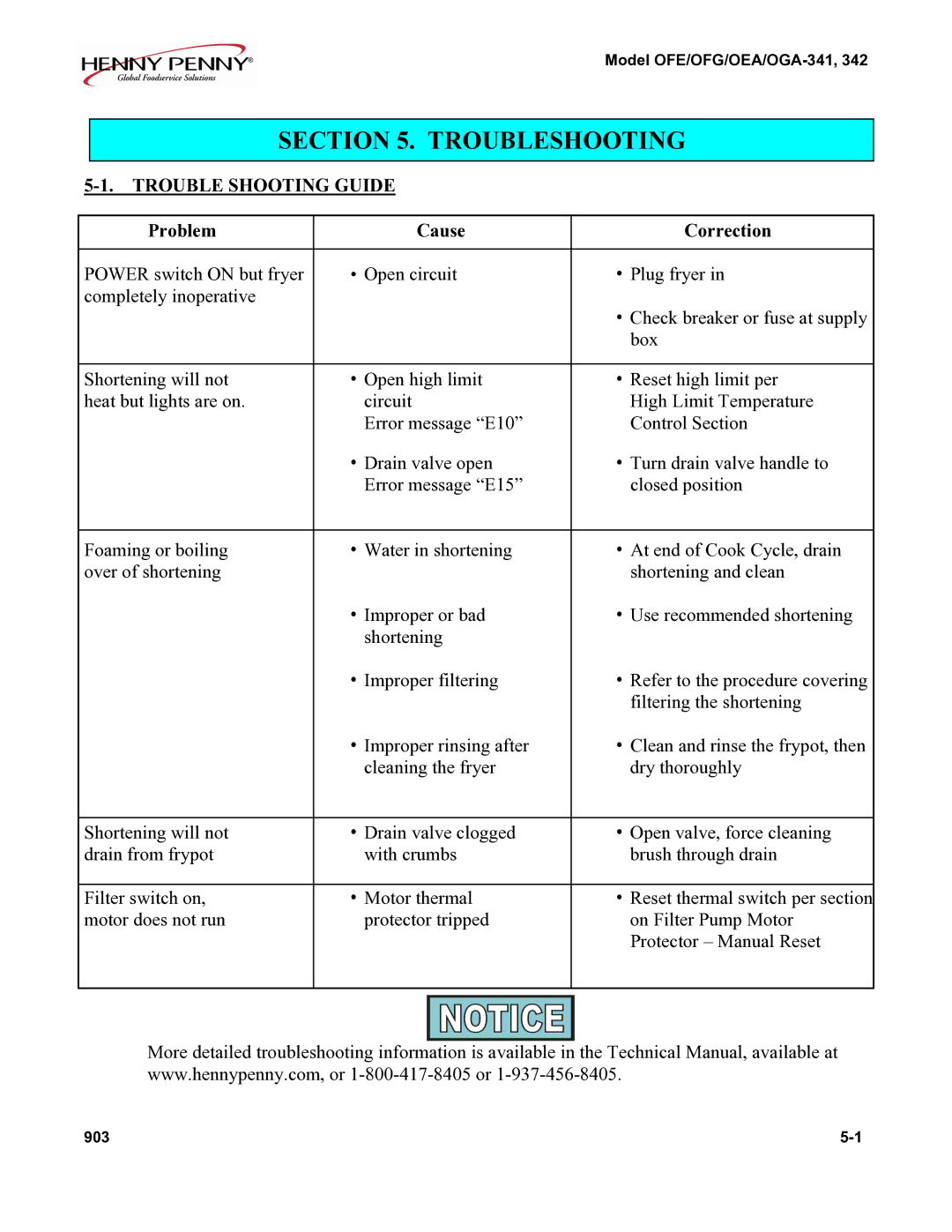

Safety is another significant attribute of the Henny Penny 341. It is equipped with a variety of safety mechanisms, including automatic pressure release valves, an insulated cover, and durable construction that withstands the rigors of a busy kitchen environment. Its efficient design minimizes the risk of burns and other hazards that can occur during frying operations.

In terms of energy efficiency, the Henny Penny 341 is designed to minimize oil usage and reduce waste. Its advanced heating system maximizes heat retention and distribution, resulting in shorter cooking times and lower energy consumption. This not only saves money but also helps restaurants contribute to environmental sustainability efforts.

The fryer also boasts easy maintenance features. Its removable oil filtration system helps extend the life of the cooking oil and enhances flavor quality by reducing the accumulation of food particles. The fryer’s design allows for easy cleaning, ensuring that hygiene standards are met without excessive downtime.

Overall, the Henny Penny 341 stands out as a reliable and innovative solution for commercial frying needs. Its combination of efficiency, safety, and ease of use makes it an essential tool for any kitchen aiming to deliver high-quality fried products while optimizing operating costs.