PROJECT

QUANTITY

ITEM NO

MODEL | ClassicCombi™ Combi Oven | ||

|

|

| Electric or gas |

|

|

| |

|

|

|

|

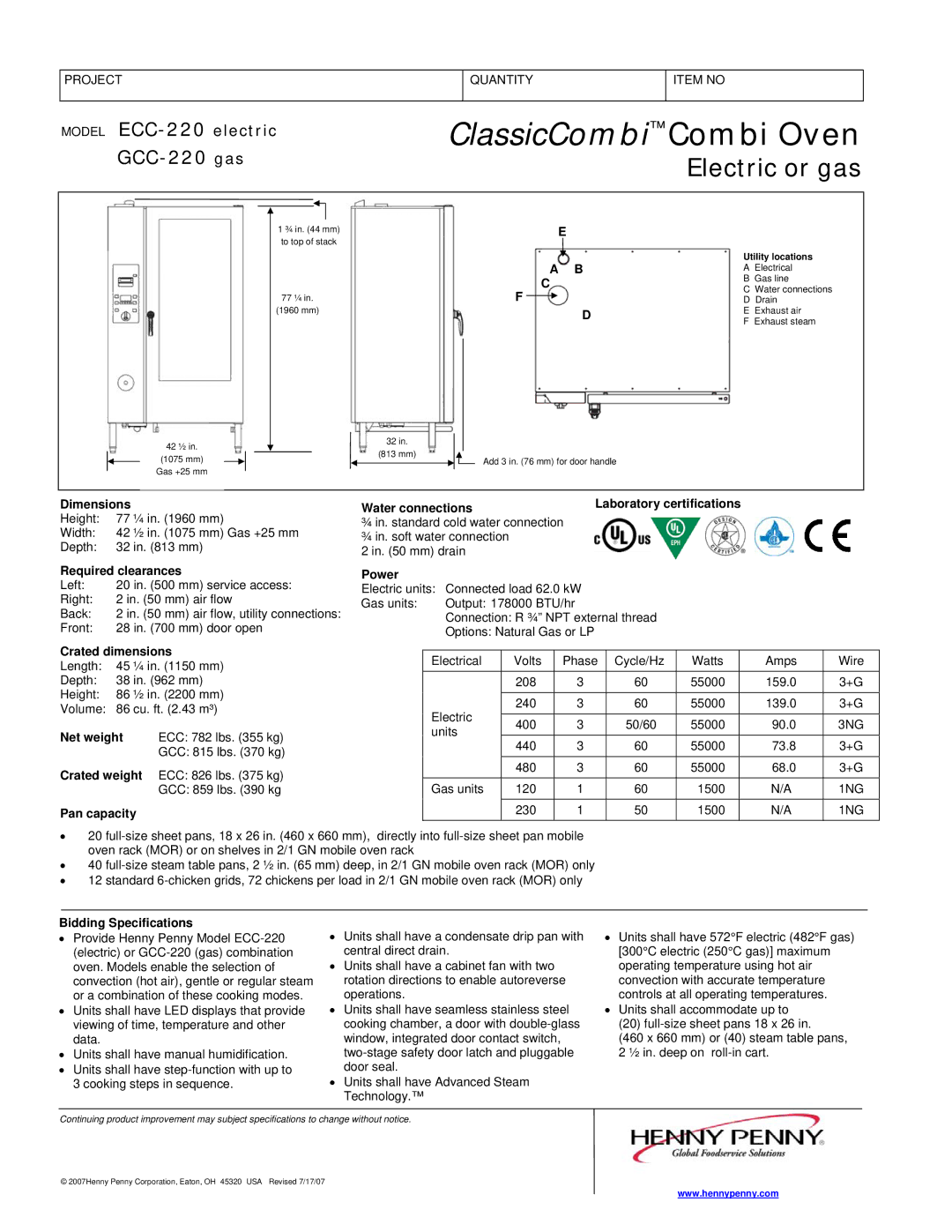

1 ¾ in. (44 mm) |

| E |

|

to top of stack |

|

|

|

| A | B | Utility locations |

| A Electrical | ||

| C |

| B Gas line |

77 ¼ in. |

| C Water connections | |

F |

| D Drain | |

(1960 mm) |

| D | E Exhaust air |

|

| F Exhaust steam | |

|

|

| |

42 ½ in.

(1075 mm)

Gas +25 mm

32 in. |

|

(813 mm) | Add 3 in. (76 mm) for door handle |

|

Dimensions

Height: 77 ¼ in. (1960 mm)

Width: 42 ½ in. (1075 mm) Gas +25 mm

Depth: 32 in. (813 mm)

Required clearances

Left: | 20 in. (500 mm) service access: |

Right: | 2 in. (50 mm) air flow |

Back: | 2 in. (50 mm) air flow, utility connections: |

Front: | 28 in. (700 mm) door open |

Crated dimensions

Length: 45 ¼ in. (1150 mm)

Depth: 38 in. (962 mm)

Height: 86 ½ in. (2200 mm)

Volume: 86 cu. ft. (2.43 m³)

Net weight ECC: 782 lbs. (355 kg) GCC: 815 lbs. (370 kg)

Crated weight ECC: 826 lbs. (375 kg) GCC: 859 lbs. (390 kg

Pan capacity

Water connections | Laboratory certifications |

|

¾in. standard cold water connection

¾in. soft water connection

2 in. (50 mm) drain

Power

Electric units: Connected load 62.0 kW

Gas units: Output: 178000 BTU/hr

Connection: R ¾” NPT external thread

Options: Natural Gas or LP

Electrical | Volts | Phase | Cycle/Hz | Watts | Amps | Wire | |

|

|

|

|

|

|

| |

| 208 | 3 | 60 | 55000 | 159.0 | 3+G | |

|

|

|

|

|

|

| |

Electric | 240 | 3 | 60 | 55000 | 139.0 | 3+G | |

|

|

|

|

|

| ||

400 | 3 | 50/60 | 55000 | 90.0 | 3NG | ||

units | |||||||

|

|

|

|

|

| ||

440 | 3 | 60 | 55000 | 73.8 | 3+G | ||

| |||||||

|

|

|

|

|

|

| |

| 480 | 3 | 60 | 55000 | 68.0 | 3+G | |

Gas units | 120 | 1 | 60 | 1500 | N/A | 1NG | |

|

|

|

|

|

|

| |

| 230 | 1 | 50 | 1500 | N/A | 1NG | |

|

|

|

|

|

|

|

•20

•40

•12 standard

Bidding Specifications

•Provide Henny Penny Model

•Units shall have LED displays that provide viewing of time, temperature and other data.

•Units shall have manual humidification.

•Units shall have

•Units shall have a condensate drip pan with central direct drain.

•Units shall have a cabinet fan with two rotation directions to enable autoreverse operations.

•Units shall have seamless stainless steel cooking chamber, a door with

•Units shall have Advanced Steam Technology.™

•Units shall have 572°F electric (482°F gas) [300°C electric (250°C gas)] maximum operating temperature using hot air convection with accurate temperature controls at all operating temperatures.

•Units shall accommodate up to

(20)

(460 x 660 mm) or (40) steam table pans,

2 ½ in. deep on

Continuing product improvement may subject specifications to change without notice.

© 2007Henny Penny Corporation, Eaton, OH 45320 USA Revised 7/17/07

www.hennypenny.com