OSAA specifications

Hill Phoenix OSAA, or the Open Systems Architecture for Automation, represents a significant advancement in the field of commercial refrigeration and foodservice equipment. This innovative platform from Hill Phoenix is engineered to meet the evolving needs of retailers and foodservice operators, focusing on efficiency, sustainability, and operational flexibility.One of the main features of the Hill Phoenix OSAA is its modular design. This allows for easy customization and scalability, enabling operators to tailor their refrigeration systems according to specific needs. The modularity also facilitates future upgrades, ensuring that the system remains relevant as technology advances and business requirements change.

The OSAA platform integrates cutting-edge technologies such as IoT (Internet of Things) connectivity and advanced sensors. This integration allows for real-time monitoring and control of refrigeration units, enabling operators to track performance metrics, energy consumption, and maintenance needs remotely. With the ability to receive alerts and notifications, operators can promptly address issues before they escalate, reducing downtime and enhancing energy efficiency.

Another core characteristic of Hill Phoenix OSAA is its focus on sustainability. The platform supports eco-friendly refrigerants and emphasizes energy-efficient operation, which helps organizations reduce their carbon footprint. Additionally, Hill Phoenix provides tools and resources that assist operators in achieving their sustainability goals, such as compliance with environmental regulations and reducing waste.

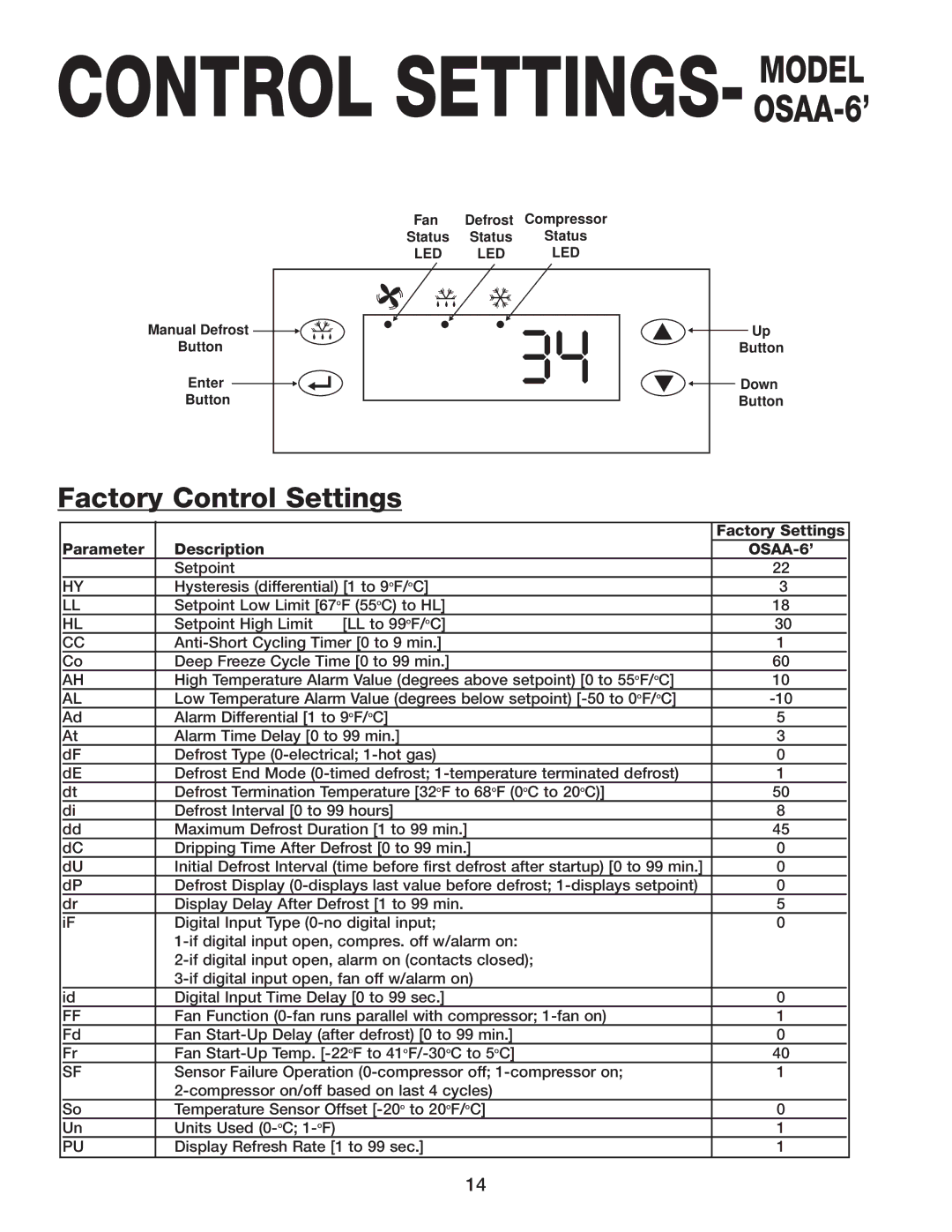

Customization extends beyond the physical system to include software solutions. The OSAA platform features intuitive software designed for easy navigation and control. Operators can set parameters, analyze data, and generate reports to gain insights into their operations. This data-driven approach empowers users to make informed decisions that can lead to cost savings and enhanced performance.

Furthermore, Hill Phoenix OSAA is designed with user-friendliness in mind. Its straightforward interface ensures that staff can quickly learn to operate it, minimizing training time and maximizing productivity. The design pays close attention to ergonomics, ensuring that equipment is accessible and easy to use.

In summary, Hill Phoenix OSAA is a groundbreaking platform that revolutionizes the refrigeration landscape with its modular design, IoT integration, sustainability focus, customizable software solutions, and user-friendly interface. These features together create a system that not only meets current demands but is also adaptable for the future, making it a preferred choice for those in the retail and foodservice sectors.