Pressure Control Repair

Motor control board removal

1.

Relieve pressure; page 3.

2.Remove screws (25, 26) and lower heat sink (22) and motor control board (22a). See Fig. 12.

3.Disconnect wires (C), (D), (96), (E) and 108 from motor control board (22a). See Fig. 4.

4.Disconnect potentiometer (77) and transducer (67) from motor control board (22a).

5.Remove four screws and motor control board (22a).

6.Install new motor control board (22a) with four screws. Reconnect all wires and secure heat sink (22) to junction box (20).

![]() CAUTION

CAUTION

To reduce the risk of a malfunction:

SBe sure the flat blade of the insulated male connector is centered in the

SRoute all wires carefully to avoid interference with the motor control board or junction box.

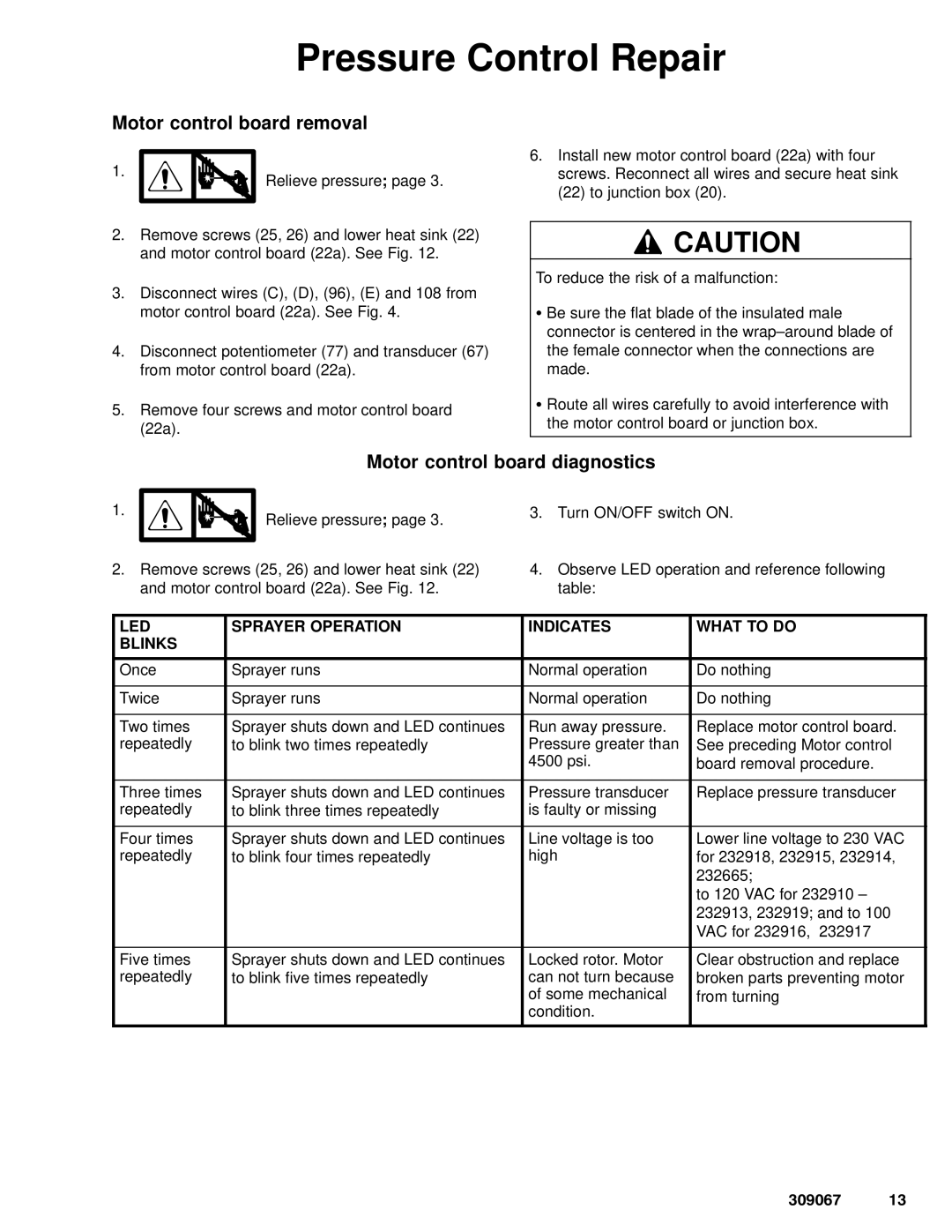

Motor control board diagnostics

1.

Relieve pressure; page 3.

2.Remove screws (25, 26) and lower heat sink (22) and motor control board (22a). See Fig. 12.

3.Turn ON/OFF switch ON.

4.Observe LED operation and reference following table:

LED | SPRAYER OPERATION | INDICATES | WHAT TO DO |

BLINKS |

|

|

|

|

|

|

|

Once | Sprayer runs | Normal operation | Do nothing |

|

|

|

|

Twice | Sprayer runs | Normal operation | Do nothing |

|

|

|

|

Two times | Sprayer shuts down and LED continues | Run away pressure. | Replace motor control board. |

repeatedly | to blink two times repeatedly | Pressure greater than | See preceding Motor control |

|

| 4500 psi. | board removal procedure. |

|

|

|

|

Three times | Sprayer shuts down and LED continues | Pressure transducer | Replace pressure transducer |

repeatedly | to blink three times repeatedly | is faulty or missing |

|

|

|

|

|

Four times | Sprayer shuts down and LED continues | Line voltage is too | Lower line voltage to 230 VAC |

repeatedly | to blink four times repeatedly | high | for 232918, 232915, 232914, |

|

|

| 232665; |

|

|

| to 120 VAC for 232910 – |

|

|

| 232913, 232919; and to 100 |

|

|

| VAC for 232916, 232917 |

|

|

|

|

Five times | Sprayer shuts down and LED continues | Locked rotor. Motor | Clear obstruction and replace |

repeatedly | to blink five times repeatedly | can not turn because | broken parts preventing motor |

|

| of some mechanical | from turning |

|

| condition. |

|

|

|

|

|

309067 13