Grounding

![]() WARNING

WARNING

Improper installation or alteration of grounding plug results in risk of electric shock, fire or explosion that could cause serious injury or death.

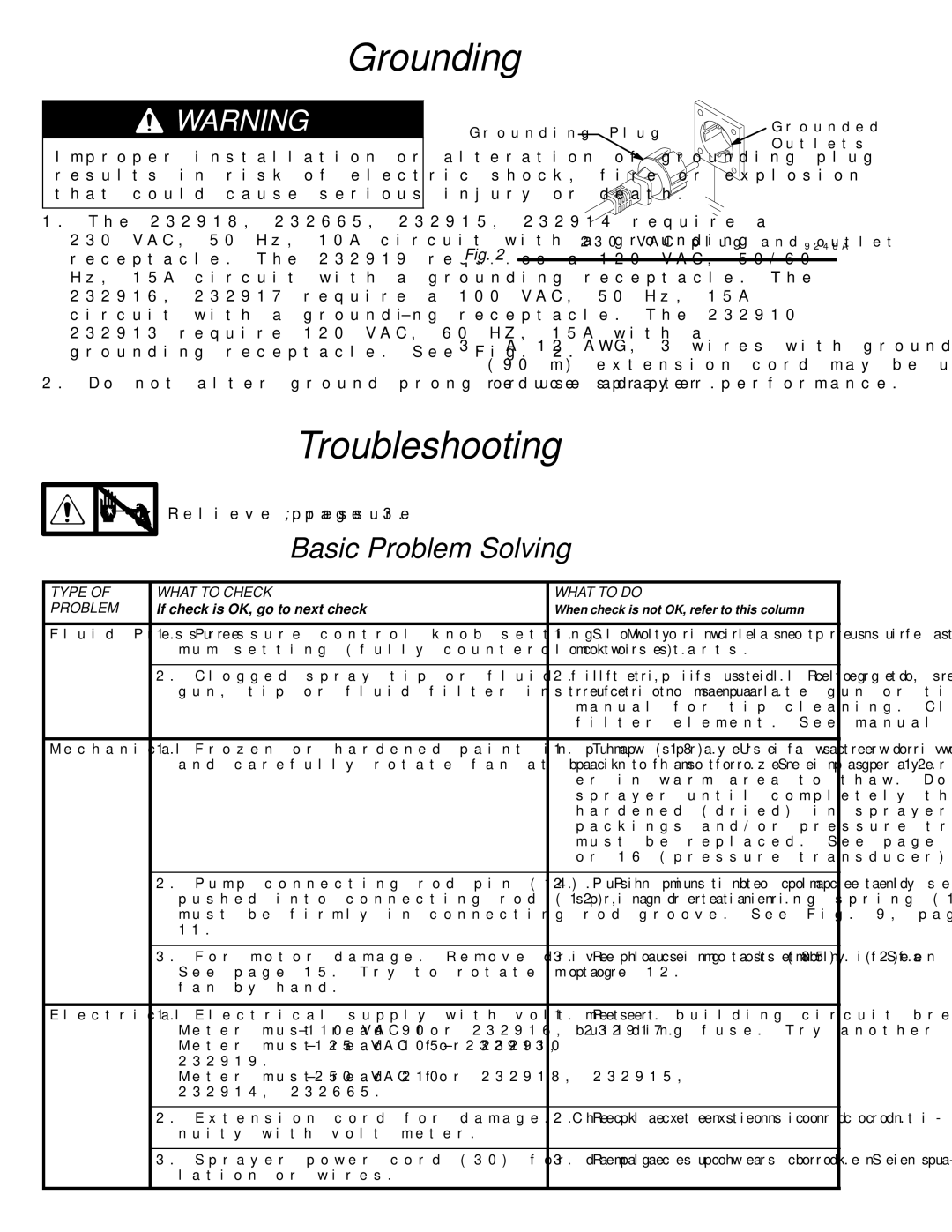

1.The 232918, 232665, 232915, 232914 require a 230 VAC, 50 Hz, 10A circuit with a grounding receptacle. The 232919 requires a 120 VAC, 50/60 Hz, 15A circuit with a grounding receptacle. The 232916, 232917 require a 100 VAC, 50 Hz, 15A circuit with a grounding receptacle. The 232910 – 232913 require 120 VAC, 60 HZ, 15A with a grounding receptacle. See Fig. 2.

2.Do not alter ground prong or use adapter.

Grounding Plug | Grounded | |

Outlets | ||

|

Fig. 2 | 230 VAC plug and outlet | 9248A |

|

|

3.A 12 AWG, 3 wires with grounding prong, 300 ft (90 m) extension cord may be used. Long lengths reduce sprayer performance.

Troubleshooting

Relieve pressure; page 3.

Basic Problem Solving

TYPE OF | WHAT TO CHECK | WHAT TO DO | ||

PROBLEM | If check is OK, go to next check | When check is not OK, refer to this column | ||

|

|

|

|

|

Fluid Pressure | 1. | Pressure control knob setting. Motor will not run if at mini- | 1. | Slowly increase pressure setting to see if |

|

| mum setting (fully counterclockwise). |

| motor starts. |

|

|

|

|

|

| 2. | Clogged spray tip or fluid filter, if used. Refer to separate | 2. | If tip is still clogged, relieve pressure; |

|

| gun, tip or fluid filter instruction manual. |

| refer to separate gun or tip instruction |

|

|

|

| manual for tip cleaning. Clean or replace |

|

|

|

| filter element. See manual 308249. |

|

|

|

|

|

Mechanical | 1. | Frozen or hardened paint in pump (18). Use a screwdriver | 1. | Thaw sprayer if water or |

|

| and carefully rotate fan at back of motor. See page 12. |

| paint has frozen in sprayer. Place spray- |

|

|

|

| er in warm area to thaw. Do not start |

|

|

|

| sprayer until completely thawed. If paint |

|

|

|

| hardened (dried) in sprayer the pump |

|

|

|

| packings and/or pressure transducer |

|

|

|

| must be replaced. See page 11 (pump) |

|

|

|

| or 16 (pressure transducer). |

|

|

|

|

|

| 2. | Pump connecting rod pin (14). Pin must be completely | 2. | Push pin into place and secure with |

|

| pushed into connecting rod (12), and retaining spring (15) |

| spring retainer. |

|

| must be firmly in connecting rod groove. See Fig. 9, page |

|

|

|

| 11. |

|

|

|

|

|

|

|

| 3. | For motor damage. Remove drive housing assembly (2). | 3. | Replace motor (85) if fan won’t turn. See |

|

| See page 15. Try to rotate motor |

| page 12. |

|

| fan by hand. |

|

|

|

|

|

|

|

Electrical | 1. | Electrical supply with volt meter. | 1. | Reset building circuit breaker; replace |

|

| Meter must read |

| building fuse. Try another outlet. |

|

| Meter must read |

|

|

|

| 232919. |

|

|

|

| Meter must read |

|

|

|

| 232914, 232665. |

|

|

|

|

|

|

|

| 2. | Extension cord for damage. Check extension cord conti- | 2. | Replace extension cord. |

|

| nuity with volt meter. |

|

|

|

|

|

|

|

| 3. | Sprayer power cord (30) for damage such as broken insu- | 3. | Replace power cord. See page 14. |

|

| lation or wires. |

|

|

|

|

|

|

|

4309067