English

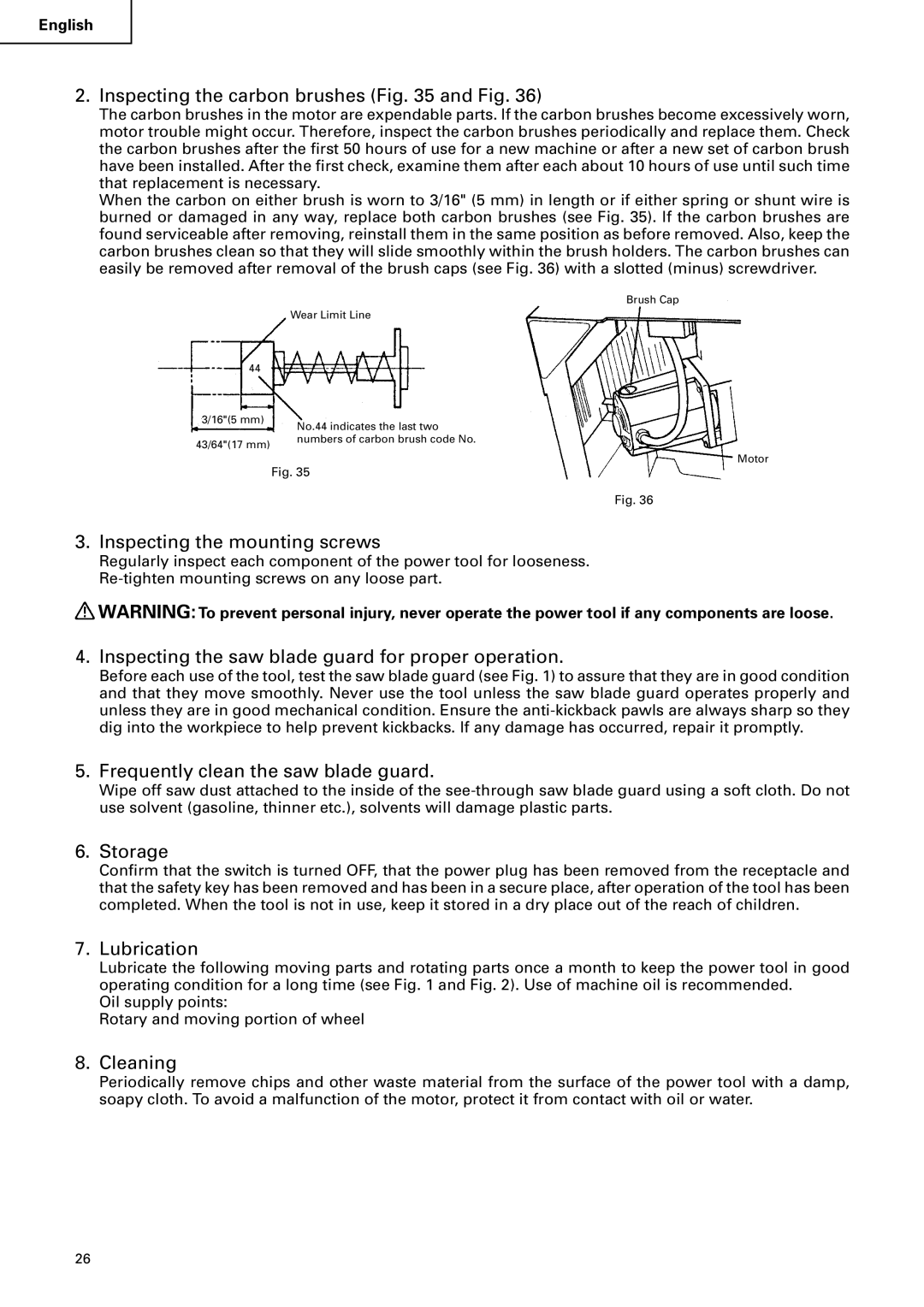

2. Inspecting the carbon brushes (Fig. 35 and Fig. 36)

The carbon brushes in the motor are expendable parts. If the carbon brushes become excessively worn, motor trouble might occur. Therefore, inspect the carbon brushes periodically and replace them. Check the carbon brushes after the first 50 hours of use for a new machine or after a new set of carbon brush have been installed. After the first check, examine them after each about 10 hours of use until such time that replacement is necessary.

When the carbon on either brush is worn to 3/16" (5 mm) in length or if either spring or shunt wire is burned or damaged in any way, replace both carbon brushes (see Fig. 35). If the carbon brushes are found serviceable after removing, reinstall them in the same position as before removed. Also, keep the carbon brushes clean so that they will slide smoothly within the brush holders. The carbon brushes can easily be removed after removal of the brush caps (see Fig. 36) with a slotted (minus) screwdriver.

Brush Cap

Wear Limit Line

44

3/16"(5 mm)

43/64"(17 mm)

No.44 indicates the last two numbers of carbon brush code No.

Motor

Fig. 35

Fig. 36

3. Inspecting the mounting screws

Regularly inspect each component of the power tool for looseness.

![]() WARNING: To prevent personal injury, never operate the power tool if any components are loose.

WARNING: To prevent personal injury, never operate the power tool if any components are loose.

4. Inspecting the saw blade guard for proper operation.

Before each use of the tool, test the saw blade guard (see Fig. 1) to assure that they are in good condition and that they move smoothly. Never use the tool unless the saw blade guard operates properly and unless they are in good mechanical condition. Ensure the

5. Frequently clean the saw blade guard.

Wipe off saw dust attached to the inside of the

6. Storage

Confirm that the switch is turned OFF, that the power plug has been removed from the receptacle and that the safety key has been removed and has been in a secure place, after operation of the tool has been completed. When the tool is not in use, keep it stored in a dry place out of the reach of children.

7. Lubrication

Lubricate the following moving parts and rotating parts once a month to keep the power tool in good operating condition for a long time (see Fig. 1 and Fig. 2). Use of machine oil is recommended.

Oil supply points:

Rotary and moving portion of wheel

8. Cleaning

Periodically remove chips and other waste material from the surface of the power tool with a damp, soapy cloth. To avoid a malfunction of the motor, protect it from contact with oil or water.

26