CUTTING WHEEL ASSEMBLY

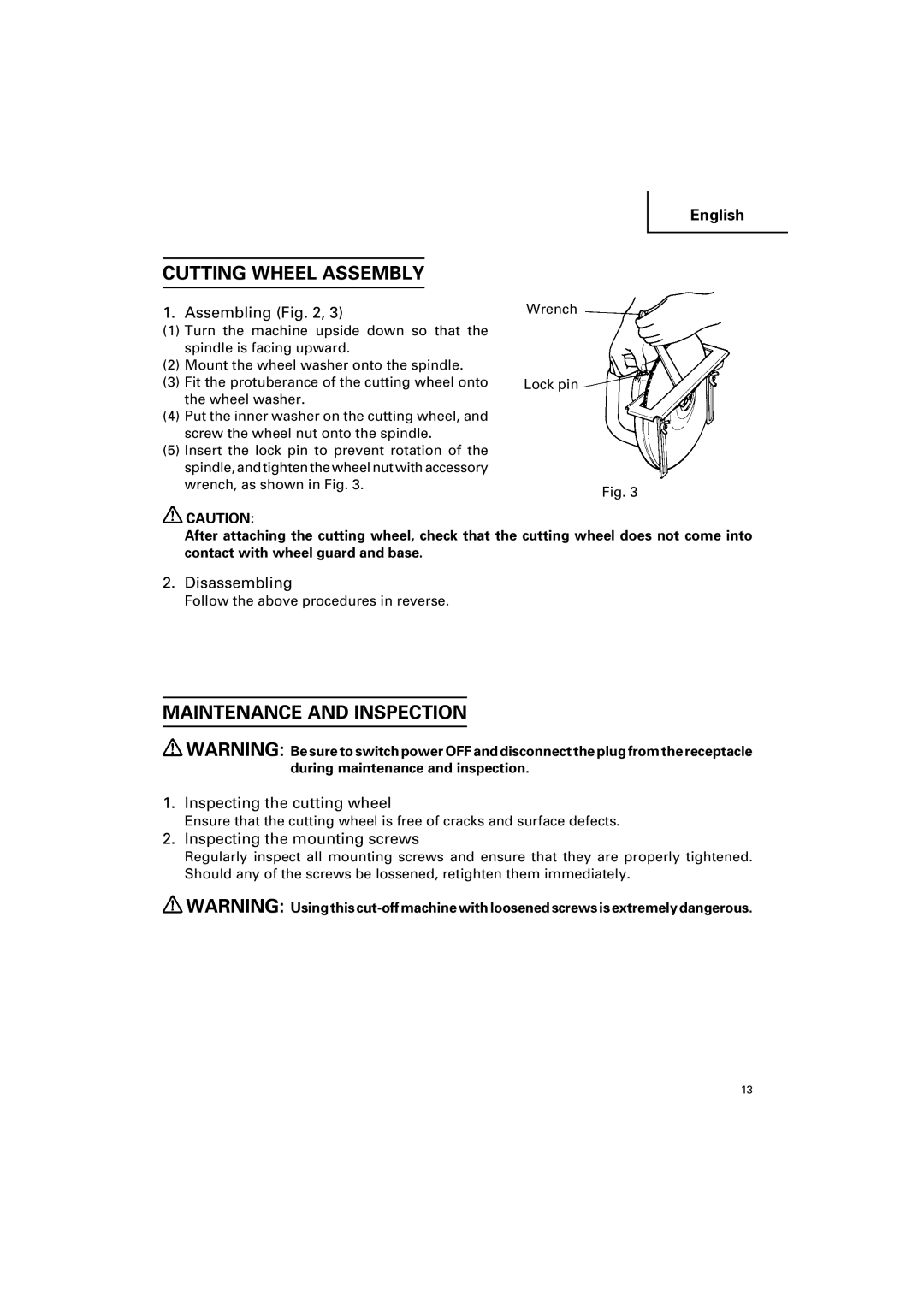

1. Assembling (Fig. 2, 3)

(1)Turn the machine upside down so that the spindle is facing upward.

(2)Mount the wheel washer onto the spindle.

(3)Fit the protuberance of the cutting wheel onto the wheel washer.

(4)Put the inner washer on the cutting wheel, and screw the wheel nut onto the spindle.

(5)Insert the lock pin to prevent rotation of the spindle, and tighten the wheel nut with accessory wrench, as shown in Fig. 3.

English

Wrench

Lock pin

Fig. 3

![]() CAUTION:

CAUTION:

After attaching the cutting wheel, check that the cutting wheel does not come into contact with wheel guard and base.

2.Disassembling

Follow the above procedures in reverse.

MAINTENANCE AND INSPECTION

![]() WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

1.Inspecting the cutting wheel

Ensure that the cutting wheel is free of cracks and surface defects.

2.Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be lossened, retighten them immediately.

![]() WARNING: Using this

WARNING: Using this

13