|

|

| English | |

|

|

|

|

|

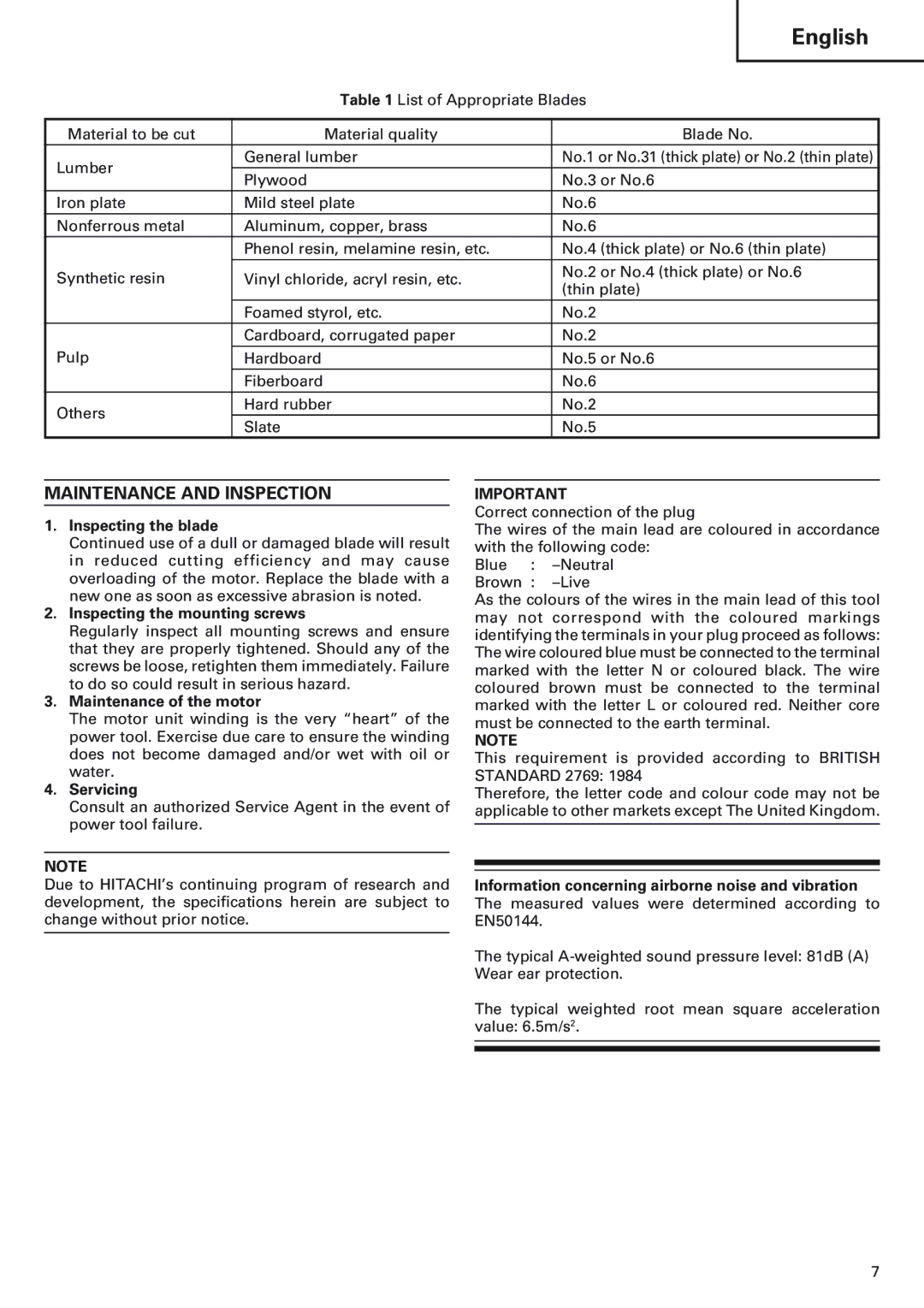

| Table 1 List of Appropriate Blades | |||

|

|

|

| |

Material to be cut | Material quality | Blade No. |

| |

Lumber | General lumber | No.1 or No.31 (thick plate) or No.2 (thin plate) |

| |

Plywood | No.3 or No.6 |

| ||

|

| |||

Iron plate | Mild steel plate | No.6 |

| |

Nonferrous metal | Aluminum, copper, brass | No.6 |

| |

| Phenol resin, melamine resin, etc. | No.4 (thick plate) or No.6 (thin plate) |

| |

Synthetic resin | Vinyl chloride, acryl resin, etc. | No.2 or No.4 (thick plate) or No.6 |

| |

(thin plate) |

| |||

|

|

| ||

| Foamed styrol, etc. | No.2 |

| |

| Cardboard, corrugated paper | No.2 |

| |

Pulp | Hardboard | No.5 or No.6 |

| |

| Fiberboard | No.6 |

| |

Others | Hard rubber | No.2 |

| |

Slate | No.5 |

| ||

|

| |||

MAINTENANCE AND INSPECTION

1.Inspecting the blade

Continued use of a dull or damaged blade will result in reduced cutting efficiency and may cause overloading of the motor. Replace the blade with a new one as soon as excessive abrasion is noted.

2.Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be loose, retighten them immediately. Failure to do so could result in serious hazard.

3.Maintenance of the motor

The motor unit winding is the very “heart” of the power tool. Exercise due care to ensure the winding does not become damaged and/or wet with oil or water.

4.Servicing

Consult an authorized Service Agent in the event of power tool failure.

NOTE

Due to HITACHI’s continuing program of research and development, the specifications herein are subject to change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance with the following code:

Blue :

Brown :

As the colours of the wires in the main lead of this tool may not correspond with the coloured markings identifying the terminals in your plug proceed as follows: The wire coloured blue must be connected to the terminal marked with the letter N or coloured black. The wire coloured brown must be connected to the terminal marked with the letter L or coloured red. Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH STANDARD 2769: 1984

Therefore, the letter code and colour code may not be applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration The measured values were determined according to EN50144.

The typical

The typical weighted root mean square acceleration value: 6.5m/s2.

7