English

MAINTENANCE AND INSPECTION

![]() WARNING: ⬤ Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

WARNING: ⬤ Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

⬤Using cracked, deformed or damaged wheels can lead to wheel breakage and resulting serious injury.

1.Replacing the depressed center wheel

Replace the depressed center wheel when it has been worn out to about

2.Inspecting the screws

Regularly inspect all screws and ensure that they are fully tightened. Should any of the screws be loosened, retighten them immediately.

![]() WARNING: Using this grinder with loosened screws is extremely dangerous.

WARNING: Using this grinder with loosened screws is extremely dangerous.

3. Confirm that there is no damage in the |

wheel guard, the electrical cord and the |

housing, etc. |

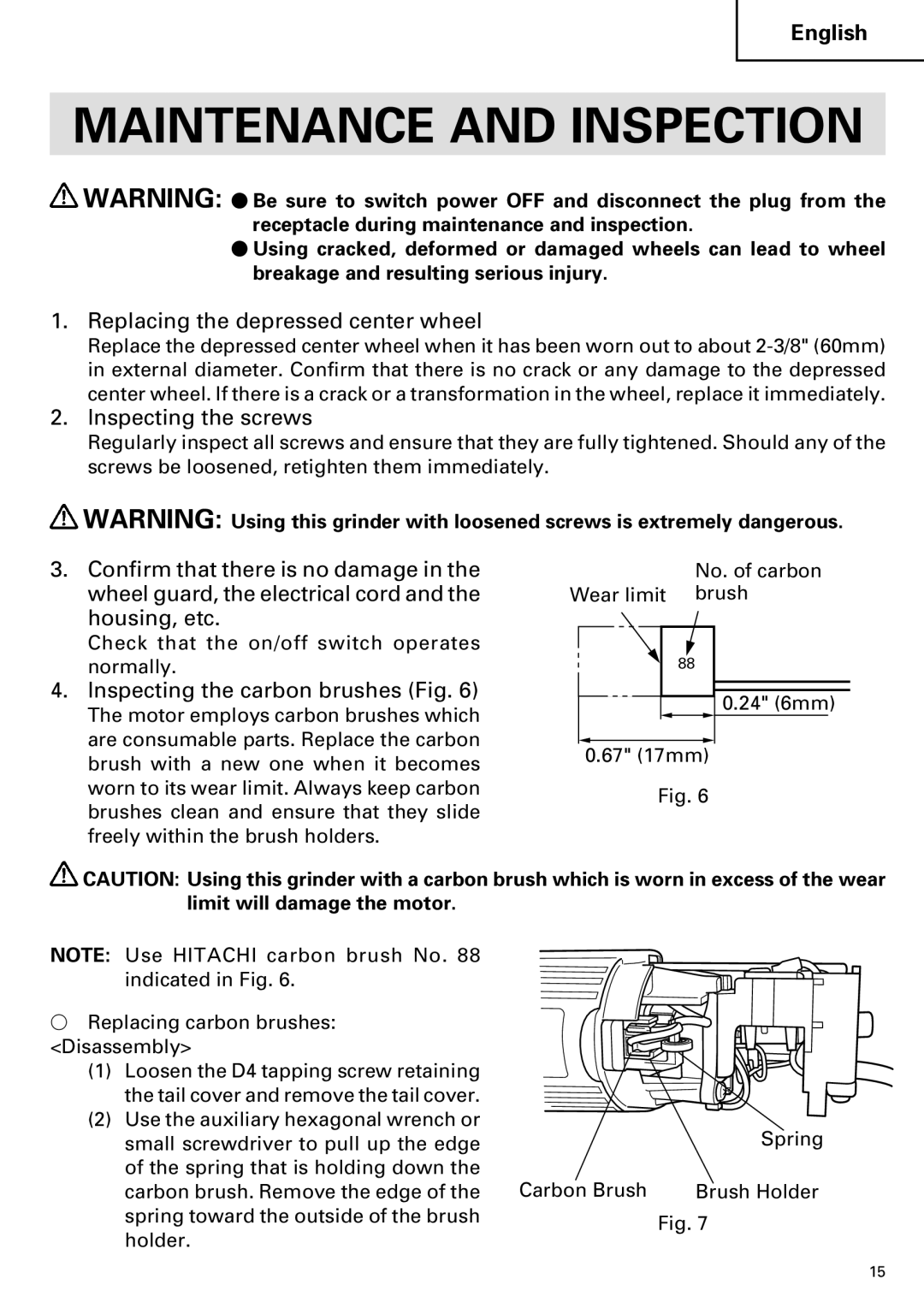

No. of carbon

Wear limit brush

Check that the on/off switch operates |

normally. |

4. Inspecting the carbon brushes (Fig. 6) |

The motor employs carbon brushes which |

are consumable parts. Replace the carbon |

brush with a new one when it becomes |

worn to its wear limit. Always keep carbon |

88 |

0.67" (17mm)

0.24" (6mm)

brushes clean and ensure that they slide |

freely within the brush holders. |

Fig. 6

![]() CAUTION: Using this grinder with a carbon brush which is worn in excess of the wear limit will damage the motor.

CAUTION: Using this grinder with a carbon brush which is worn in excess of the wear limit will damage the motor.

NOTE: Use HITACHI carbon brush No. 88 indicated in Fig. 6.

◯ Replacing carbon brushes: |

|

|

<Disassembly> |

|

|

(1) Loosen the D4 tapping screw retaining |

|

|

the tail cover and remove the tail cover. |

|

|

(2) Use the auxiliary hexagonal wrench or |

| Spring |

small screwdriver to pull up the edge |

| |

of the spring that is holding down the | Carbon Brush |

|

carbon brush. Remove the edge of the | Brush Holder | |

spring toward the outside of the brush |

| Fig. 7 |

holder. |

| |

|

|

15