L300P specifications

The Hitachi L300P is a versatile and highly efficient variable frequency drive (VFD) known for its robust performance and reliability across various industrial applications. This drive is part of Hitachi's renowned L-series, designed to provide precise motor control and energy savings, making it a popular choice among engineers and system integrators.One of the standout features of the Hitachi L300P is its advanced vector control technology. This technology enables the drive to deliver superior torque control and operational efficiency, which is crucial for applications requiring high performance and accuracy. The L300P's sensorless vector control capability allows it to maintain optimal performance even in varying load conditions, ensuring that motors run smoothly and efficiently.

The L300P also boasts a wide input voltage range, accommodating different voltage requirements from 200V to 600V. This flexibility makes it suitable for diverse global applications without the need for voltage converters. Additionally, the drive supports a broad range of output frequencies, allowing for seamless integration with various motor types.

Another significant aspect of the L300P is its built-in PLC functionality. This feature enables users to implement simple control tasks directly within the drive, reducing the need for external controllers and minimizing installation space and complexity. With programmable logic capabilities, users can optimize their processes and add custom functionalities to meet specific operational requirements.

The L300P is equipped with comprehensive protection features, including overcurrent protection, overvoltage protection, and motor stall prevention. These safety mechanisms ensure that the drive and the connected motors remain protected under adverse operating conditions, enhancing system reliability and reducing maintenance costs.

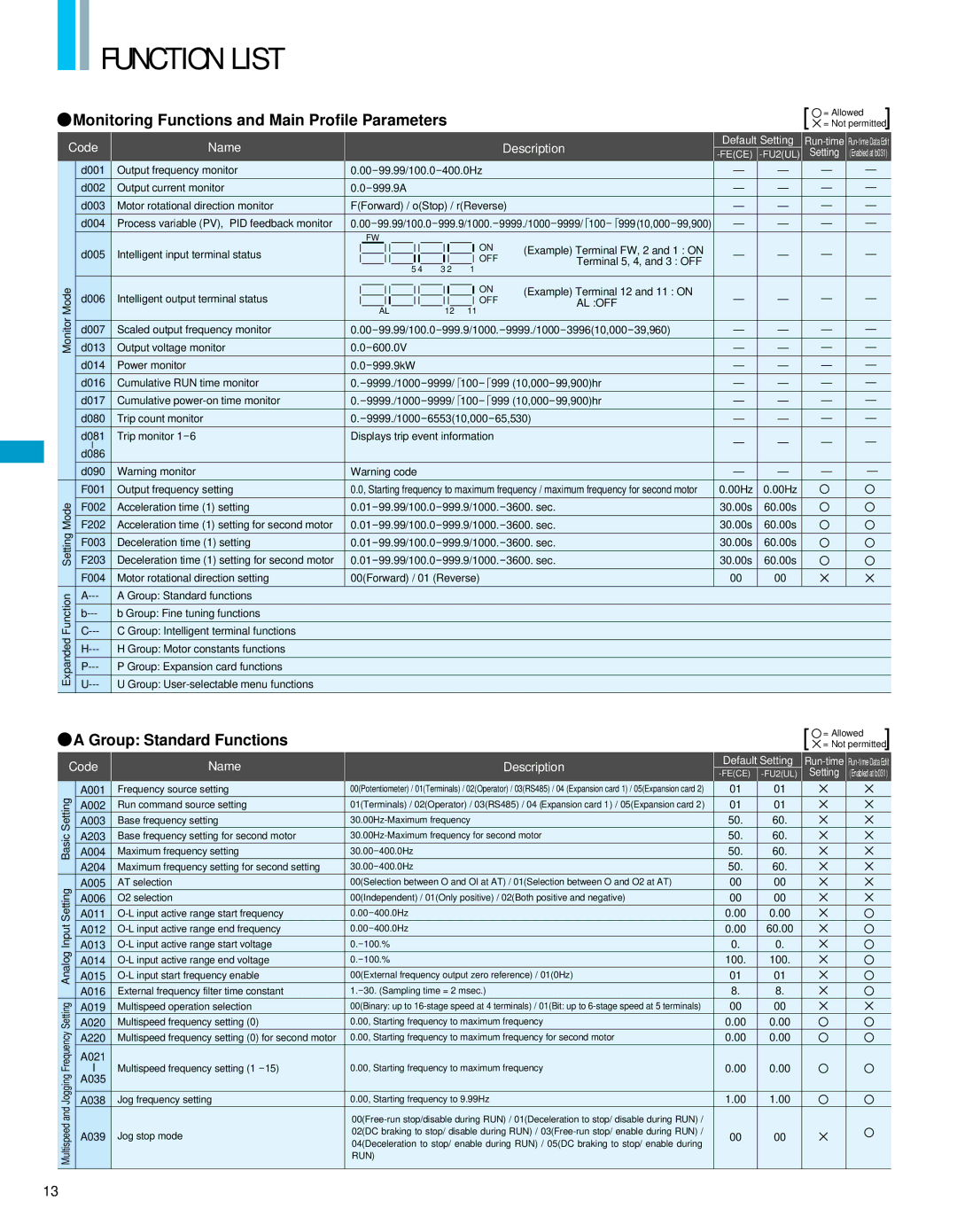

In terms of user interface, the L300P includes an intuitive keypad that allows for easy parameter setting and monitoring. The display provides real-time information about operational status and performance metrics, enabling users to make informed decisions quickly.

Energy efficiency is another key characteristic of the L300P. By utilizing advanced control algorithms and motor management techniques, the drive significantly reduces energy consumption, making it an environmentally friendly choice for industries looking to lower their carbon footprint.

Overall, the Hitachi L300P combines advanced technology, robust performance, and user-friendly features, making it a pivotal component in modern industrial automation and control systems. With its flexibility and efficiency, it stands out as a reliable solution for a wide range of applications, from HVAC systems to conveyor control and beyond.