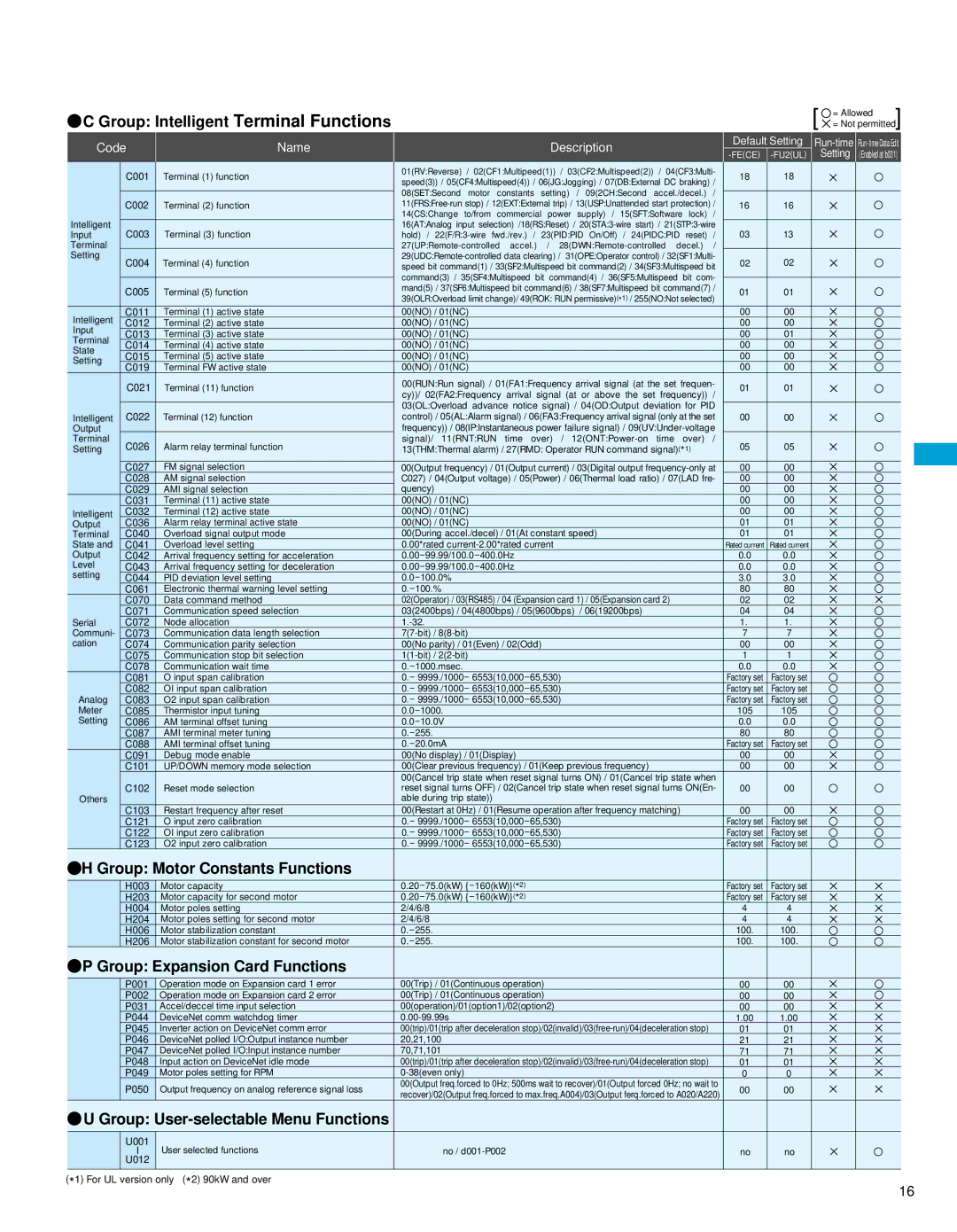

| C Group: Intelligent Terminal Functions | | | | [ | = Allowed |

| | | | = Not permitted] |

| Code | Name | Description | Default Setting | Run-timeRun-time Data Edit | | |

| -FE(CE) | -FU2(UL) | | Setting (Enabled at b031) | | |

| | | | | | |

| | C001 | Terminal (1) function | 01(RV:Reverse) / 02(CF1:Multipeed(1)) / 03(CF2:Multispeed(2)) / 04(CF3:Multi- | 18 | 18 | | | | | |

| | speed(3)) / 05(CF4:Multispeed(4)) / 06(JG:Jogging) / 07(DB:External DC braking) / | | | | | |

| | | | | | | | | | |

| | | | 08(SET:Second motor constants setting) / 09(2CH:Second accel./decel.) / | | | | | | | |

| | C002 | Terminal (2) function | 11(FRS:Free-run stop) / 12(EXT:External trip) / 13(USP:Unattended start protection) / | 16 | 16 | | | | | |

| | | | 14(CS:Change to/from commercial power supply) / 15(SFT:Software lock) / | | | | | | | |

| Intelligent | C003 | Terminal (3) function | 16(AT:Analog input selection) /18(RS:Reset) / 20(STA:3-wire start) / 21(STP:3-wire | 03 | 13 | | | | | |

| Input | hold) / 22(F/R:3-wire fwd./rev.) / 23(PID:PID On/Off) / 24(PIDC:PID reset) / | | | | | |

| Terminal | | | 27(UP:Remote-controlled accel.) / 28(DWN:Remote-controlled decel.) / | | | | | | | |

| Setting | C004 | Terminal (4) function | 29(UDC:Remote-controlled data clearing) / 31(OPE:Operator control) / 32(SF1:Multi- | 02 | 02 | | | | | |

| | speed bit command(1) / 33(SF2:Multispeed bit command(2) / 34(SF3:Multispeed bit | | | | | |

| | | | | | | | | | |

| | | | command(3) / 35(SF4:Multispeed bit command(4) / 36(SF5:Multispeed bit com- | | | | | | | |

| | | | | | | | | | |

| | C005 | Terminal (5) function | mand(5) / 37(SF6:Multispeed bit command(6) / 38(SF7:Multispeed bit command(7) / | 01 | 01 | | | | | |

| | 39(OLR:Overload limit change)/ 49(ROK: RUN permissive)(*1) / 255(NO:Not selected) | | | | | |

| | | | | | | | | | |

| Intelligent | C011 | Terminal (1) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| C012 | Terminal (2) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| Input | C013 | Terminal (3) active state | 00(NO) / 01(NC) | 00 | 01 | | | | | |

| Terminal | C014 | Terminal (4) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| State | | | | | |

| C015 | Terminal (5) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| Setting | | | | | |

| C019 | Terminal FW active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| | | | | | |

| | C021 | Terminal (11) function | 00(RUN:Run signal) / 01(FA1:Frequency arrival signal (at the set frequen- | 01 | 01 | | | | | |

| | cy))/ 02(FA2:Frequency arrival signal (at or above the set frequency)) / | | | | | |

| | | | | | | | | | |

| | | | 03(OL:Overload advance notice signal) / 04(OD:Output deviation for PID | | | | | | | |

| Intelligent | C022 | Terminal (12) function | control) / 05(AL:Alarm signal) / 06(FA3:Frequency arrival signal (only at the set | 00 | 00 | | | | | |

| Output | | | frequency)) / 08(IP:Instantaneous power failure signal) / 09(UV:Under-voltage | | | | | | | |

| Terminal | C026 | Alarm relay terminal function | signal)/ 11(RNT:RUN time over) / 12(ONT:Power-on time over) / | 05 | 05 | | | | | |

| Setting | 13(THM:Thermal alarm) / 27(RMD: Operator RUN command signal)(*1) | | | | | |

| | C027 | FM signal selection | 00(Output frequency) / 01(Output current) / 03(Digital output frequency-only at | 00 | 00 | | | | | |

| | C028 | AM signal selection | C027) / 04(Output voltage) / 05(Power) / 06(Thermal load ratio) / 07(LAD fre- | 00 | 00 | | | | | |

| | C029 | AMI signal selection | quency) | 00 | 00 | | | | | |

| | C031 | Terminal (11) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| Intelligent | C032 | Terminal (12) active state | 00(NO) / 01(NC) | 00 | 00 | | | | | |

| Output | C036 | Alarm relay terminal active state | 00(NO) / 01(NC) | 01 | 01 | | | | | |

| Terminal | C040 | Overload signal output mode | 00(During accel./decel) / 01(At constant speed) | 01 | 01 | | | | | |

| State and | C041 | Overload level setting | 0.00*rated current-2.00*rated current | Rated current | Rated current | | | | | |

| Output | C042 | Arrival frequency setting for acceleration | 0.00-99.99/100.0-400.0Hz | 0.0 | 0.0 | | | | | |

| Level | C043 | Arrival frequency setting for deceleration | 0.00-99.99/100.0-400.0Hz | 0.0 | 0.0 | | | | | |

| setting | C044 | PID deviation level setting | 0.0-100.0% | 3.0 | 3.0 | | | | | |

| | C061 | Electronic thermal warning level setting | 0.-100.% | 80 | 80 | | | | | |

| | C070 | Data command method | 02(Operator) / 03(RS485) / 04 (Expansion card 1) / 05(Expansion card 2) | 02 | 02 | | | | | |

| | C071 | Communication speed selection | 03(2400bps) / 04(4800bps) / 05(9600bps) / 06(19200bps) | 04 | 04 | | | | | |

| Serial | C072 | Node allocation | 1.-32. | 1. | 1. | | | | | |

| Communi- | C073 | Communication data length selection | 7(7-bit) / 8(8-bit) | 7 | 7 | | | | | |

| cation | C074 | Communication parity selection | 00(No parity) / 01(Even) / 02(Odd) | 00 | 00 | | | | | |

| | C075 | Communication stop bit selection | 1(1-bit) / 2(2-bit) | 1 | 1 | | | | | |

| | C078 | Communication wait time | 0.-1000.msec. | 0.0 | 0.0 | | | | | |

| | C081 | O input span calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| | C082 | OI input span calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| Analog | C083 | O2 input span calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| Meter | C085 | Thermistor input tuning | 0.0-1000. | 105 | 105 | | | | | |

| Setting | C086 | AM terminal offset tuning | 0.0-10.0V | 0.0 | 0.0 | | | | | |

| | C087 | AMI terminal meter tuning | 0.-255. | 80 | 80 | | | | | |

| | C088 | AMI terminal offset tuning | 0.-20.0mA | Factory set | Factory set | | | | | |

| | C091 | Debug mode enable | 00(No display) / 01(Display) | 00 | 00 | | | | | |

| | C101 | UP/DOWN memory mode selection | 00(Clear previous frequency) / 01(Keep previous frequency) | 00 | 00 | | | | | |

| | | | 00(Cancel trip state when reset signal turns ON) / 01(Cancel trip state when | | | | | | | |

| | C102 | Reset mode selection | reset signal turns OFF) / 02(Cancel trip state when reset signal turns ON(En- | 00 | 00 | | | | | |

| Others | | | able during trip state)) | | | | | | | |

| | C103 | Restart frequency after reset | 00(Restart at 0Hz) / 01(Resume operation after frequency matching) | 00 | 00 | | | | | |

| | C121 | O input zero calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| | C122 | OI input zero calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| | C123 | O2 input zero calibration | 0.- 9999./1000- 6553(10,000-65,530) | Factory set | Factory set | | | | | |

| H Group: Motor Constants Functions | | | | | | | | |

| | H003 | Motor capacity | 0.20-75.0(kW) {-160(kW)}(*2) | Factory set | Factory set | | | | | |

| | H203 | Motor capacity for second motor | 0.20-75.0(kW) {-160(kW)}(*2) | Factory set | Factory set | | | | | |

| | H004 | Motor poles setting | 2/4/6/8 | 4 | 4 | | | | | |

| | H204 | Motor poles setting for second motor | 2/4/6/8 | 4 | 4 | | | | | |

| | H006 | Motor stabilization constant | 0.-255. | 100. | 100. | | | | | |

| | H206 | Motor stabilization constant for second motor | 0.-255. | 100. | 100. | | | | | |

| P Group: Expansion Card Functions | | | | | | | | |

| | P001 | Operation mode on Expansion card 1 error | 00(Trip) / 01(Continuous operation) | 00 | 00 | | | | | |

| | P002 | Operation mode on Expansion card 2 error | 00(Trip) / 01(Continuous operation) | 00 | 00 | | | | | |

| | P031 | Accel/deccel time input selection | 00(operation)/01(option1)/02(option2) | 00 | 00 | | | | | |

| | P044 | DeviceNet comm watchdog timer | 0.00-99.99s | 1.00 | 1.00 | | | | | |

| | P045 | Inverter action on DeviceNet comm error | 00(trip)/01(trip after deceleration stop)/02(invalid)/03(free-run)/04(deceleration stop) | 01 | 01 | | | | | |

| | P046 | DeviceNet polled I/O:Output instance number | 20,21,100 | 21 | 21 | | | | | |

| | P047 | DeviceNet polled I/O:Input instance number | 70,71,101 | 71 | 71 | | | | | |

| | P048 | Input action on DeviceNet idle mode | 00(trip)/01(trip after deceleration stop)/02(invalid)/03(free-run)/04(deceleration stop) | 01 | 01 | | | | | |

| | P049 | Motor poles setting for RPM | 0-38(even only) | 0 | 0 | | | | | |

| | P050 | Output frequency on analog reference signal loss | 00(Output freq.forced to 0Hz; 500ms wait to recover)/01(Output forced 0Hz; no wait to | 00 | 00 | | | | | |

| | recover)/02(Output freq.forced to max.freq.A004)/03(Output ferq.forced to A020/A220) | | | | | |

| | | | | | | | | | |

| U Group: User-selectable Menu Functions | | | | | | | | |

| | U001 | User selected functions | | | | | | | | |

| | I | no / d001-P002 | no | no | | | | | |

| | U012 | | | | | | | | | |

| | | | | | | | | | | |

(*1) For UL version only (*2) 90kW and over | | | | | 16 |

| | | | | | | |