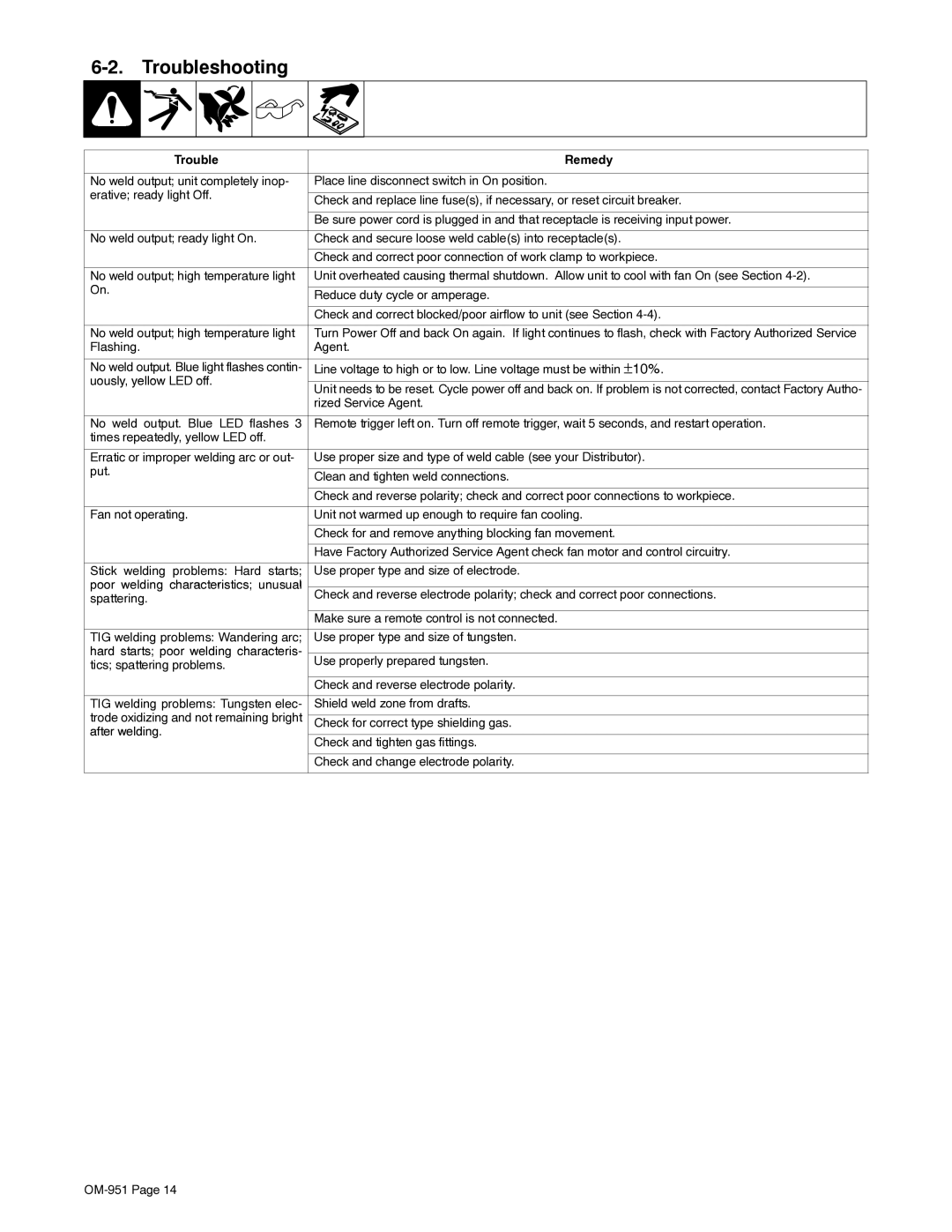

6-2. Troubleshooting

|

|

|

|

| |

|

|

|

|

| |

| Trouble | Remedy | |||

|

| ||||

No weld output; unit completely inop- | Place line disconnect switch in On position. | ||||

erative; ready light Off. |

| ||||

Check and replace line fuse(s), if necessary, or reset circuit breaker. | |||||

|

|

|

| ||

|

|

|

|

| |

|

|

|

| Be sure power cord is plugged in and that receptacle is receiving input power. | |

|

| ||||

No weld output; ready light On. | Check and secure loose weld cable(s) into receptacle(s). | ||||

|

|

|

|

| |

|

|

|

| Check and correct poor connection of work clamp to workpiece. | |

|

| ||||

No weld output; high temperature light | Unit overheated causing thermal shutdown. Allow unit to cool with fan On (see Section | ||||

On. |

| ||||

Reduce duty cycle or amperage. | |||||

|

|

|

| ||

|

|

|

|

| |

|

|

|

| Check and correct blocked/poor airflow to unit (see Section | |

|

| ||||

No weld output; high temperature light | Turn Power Off and back On again. If light continues to flash, check with Factory Authorized Service | ||||

Flashing. | Agent. | ||||

|

| ||||

No weld output. Blue light flashes contin- | Line voltage to high or to low. Line voltage must be within ±10%. | ||||

uously, yellow LED off. |

| ||||

Unit needs to be reset. Cycle power off and back on. If problem is not corrected, contact Factory Autho- | |||||

|

|

|

| ||

|

|

|

| rized Service Agent. | |

|

| ||||

No weld output. Blue LED flashes 3 | Remote trigger left on. Turn off remote trigger, wait 5 seconds, and restart operation. | ||||

times repeatedly, yellow LED off. |

| ||||

|

| ||||

Erratic or improper welding arc or out- | Use proper size and type of weld cable (see your Distributor). | ||||

put. |

| ||||

Clean and tighten weld connections. | |||||

|

|

|

| ||

|

|

|

|

| |

|

|

|

| Check and reverse polarity; check and correct poor connections to workpiece. | |

|

| ||||

Fan not operating. | Unit not warmed up enough to require fan cooling. | ||||

|

|

|

|

| |

|

|

|

| Check for and remove anything blocking fan movement. | |

|

|

|

|

| |

|

|

|

| Have Factory Authorized Service Agent check fan motor and control circuitry. | |

|

| ||||

Stick welding problems: Hard starts; | Use proper type and size of electrode. | ||||

poor welding characteristics; unusual |

| ||||

Check and reverse electrode polarity; check and correct poor connections. | |||||

spattering. |

| ||||

|

|

|

| Make sure a remote control is not connected. | |

|

| ||||

TIG welding problems: Wandering arc; | Use proper type and size of tungsten. | ||||

hard starts; poor welding characteris- |

| ||||

Use properly prepared tungsten. | |||||

tics; spattering problems. |

| ||||

|

|

|

| Check and reverse electrode polarity. | |

|

| ||||

TIG welding problems: Tungsten elec- | Shield weld zone from drafts. | ||||

trode oxidizing and not remaining bright |

| ||||

Check for correct type shielding gas. | |||||

after welding. |

| ||||

Check and tighten gas fittings. | |||||

|

|

|

| ||

|

|

|

|

| |

|

|

|

| Check and change electrode polarity. | |

|

|

|

|

| |