5-4. Process/Polarity Table

Process | Polarity | Cable Connections | ||

|

| |||

Cable To Gun | Cable To Work | |||

|

| |||

|

|

|

| |

GMAW − Solid wire with shield- | DCEP − Reverse polarity | Connect to positive (+) out- | Connect to negative (−) output | |

ing gas |

| put terminal | terminal | |

|

|

|

| |

FCAW − | DCEN − Straight Polarity | Connect to negative (−) | Connect to positive (+) output | |

no shielding gas |

| output terminal | terminal | |

|

|

|

| |

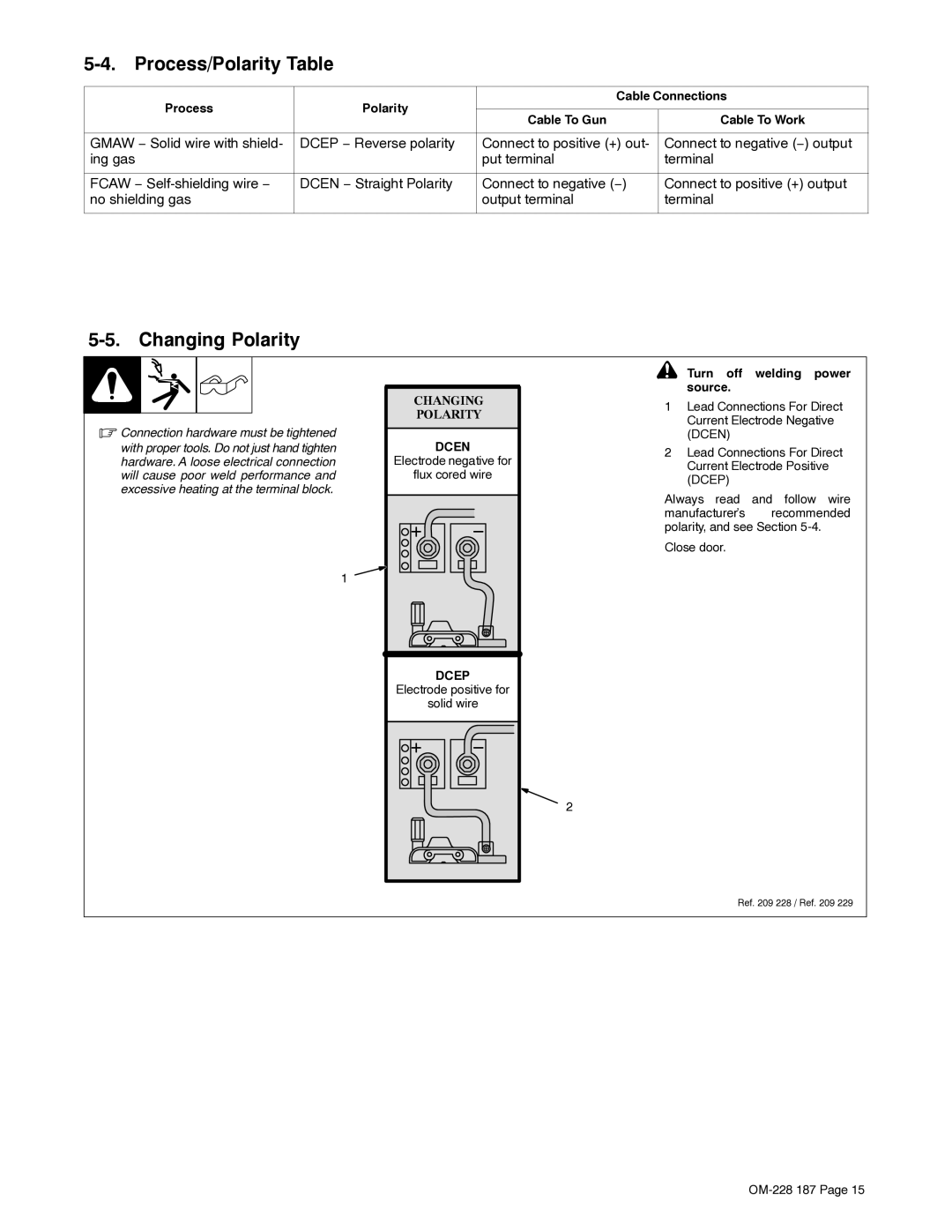

5-5. Changing Polarity

.Connection hardware must be tightened

with proper tools. Do not just hand tighten hardware. A loose electrical connection will cause poor weld performance and excessive heating at the terminal block.

CHANGING |

POLARITY |

DCEN |

Electrode negative for |

flux cored wire |

1 |

DCEP |

Electrode positive for |

solid wire |

2 |

! Turn off welding power source.

1Lead Connections For Direct Current Electrode Negative (DCEN)

2Lead Connections For Direct Current Electrode Positive (DCEP)

Always read and follow wire manufacturer’s recommended polarity, and see Section

Close door.

Ref. 209 228 / Ref. 209 229