SECTION 4 – INSTALLATION

4-1. Installing Welding Generator

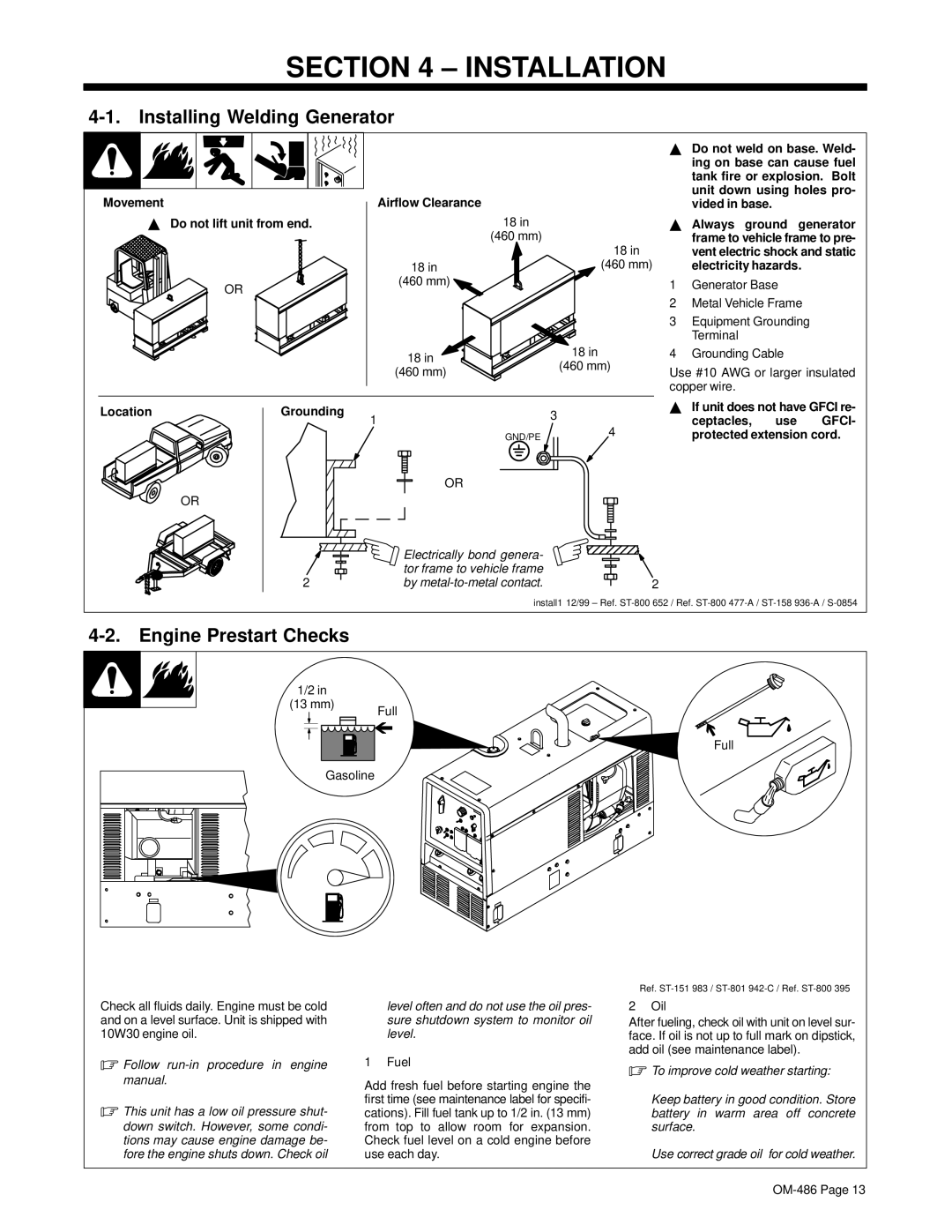

Movement

YDo not lift unit from end.

OR

Airflow Clearance

18in

(460 mm)

| 18 in |

18 in | (460 mm) |

(460 mm) |

| |

18 in | 18 in | |

(460 mm) | ||

(460 mm) | ||

|

YDo not weld on base. Weld- ing on base can cause fuel tank fire or explosion. Bolt unit down using holes pro- vided in base.

YAlways ground generator frame to vehicle frame to pre- vent electric shock and static electricity hazards.

1Generator Base

2Metal Vehicle Frame

3Equipment Grounding Terminal

4Grounding Cable

Use #10 AWG or larger insulated copper wire.

Location

OR

Grounding | 3 | Y If unit does not have GFCI re- | |||

1 | ceptacles, | use | GFCI- | ||

4 | |||||

GND/PE | protected extension cord. | ||||

OR

| Electrically bond genera- |

|

| tor frame to vehicle frame |

|

2 | by | 2 |

install1 12/99 – Ref.

4-2. Engine Prestart Checks

1/2 in

(13 mm)

Full

Full

Gasoline

Check all fluids daily. Engine must be cold and on a level surface. Unit is shipped with 10W30 engine oil.

.Follow run-in procedure in engine manual.

.This unit has a low oil pressure shut- down switch. However, some condi- tions may cause engine damage be- fore the engine shuts down. Check oil

level often and do not use the oil pres- sure shutdown system to monitor oil level.

1 Fuel

Add fresh fuel before starting engine the first time (see maintenance label for specifi- cations). Fill fuel tank up to 1/2 in. (13 mm) from top to allow room for expansion. Check fuel level on a cold engine before use each day.

Ref.

2 Oil

After fueling, check oil with unit on level sur- face. If oil is not up to full mark on dipstick, add oil (see maintenance label).

.To improve cold weather starting:

Keep battery in good condition. Store battery in warm area off concrete surface.

Use correct grade oil for cold weather.