SECTION 3 – OPERATION

3-1. Controls

12

OFF | POWER |

| |

| CUP |

ON | TEMP |

| |

| INPUT VOLTAGE |

1Power Switch

2Power Light

Use light to tell if unit is energized and ready to operate. Light goes off if input power is not with specified range (see trouble light infor- mation).

3

3 Trouble Light

Trouble light comes on for the following conditions:

aIf cup is removed from torch (unit power must be turned off and back on again)

|

| 196 630 |

b | If unit overheats | |

c | If | input power is not within |

specification (93 to 137 vac). If input power is outside of specified range, cycle power by placing the power switch in the off position and back on again. Check input power if problem continues.

3-2. Cutting Speed

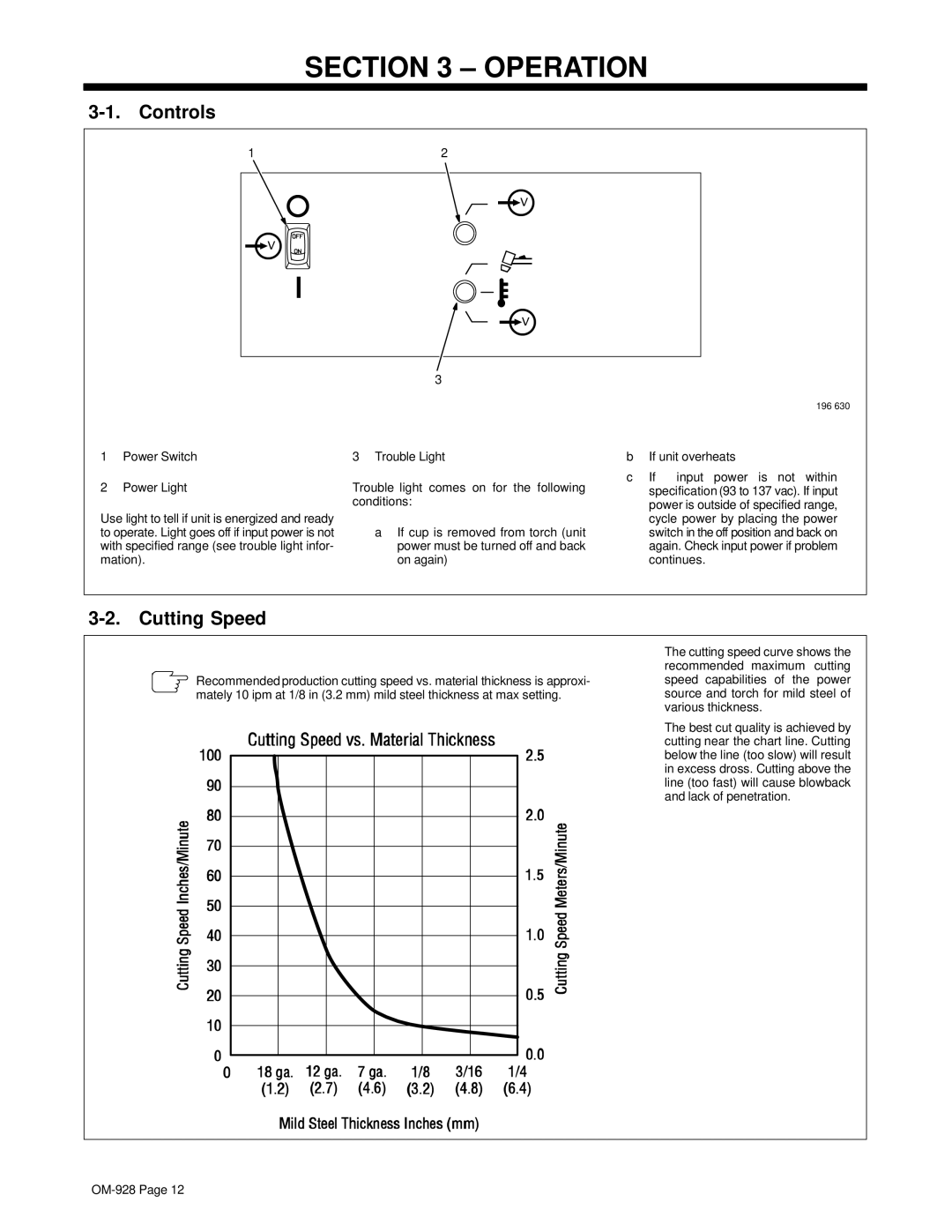

Recommended production cutting speed vs. material thickness is approxi- mately 10 ipm at 1/8 in (3.2 mm) mild steel thickness at max setting.

The cutting speed curve shows the recommended maximum cutting speed capabilities of the power source and torch for mild steel of various thickness.

The best cut quality is achieved by cutting near the chart line. Cutting below the line (too slow) will result in excess dross. Cutting above the line (too fast) will cause blowback and lack of penetration.